Description

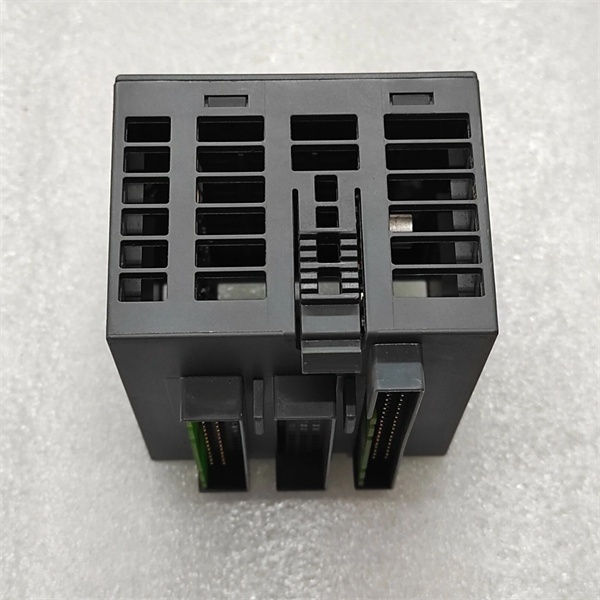

ABB 1SAP240000R0001 DI524

-

Model Number: DI524 -

Product Code: 1SAP240000R0001 -

Manufacturer: ABB -

Product Type: Digital Input Module -

Number of Channels: 16 (individually isolated) -

Input Type: Dry contact (relay, 24V DC), Solid-state (transistor, 24V DC) -

Input Voltage: 24V DC nominal (18-30V DC range) -

Isolation Voltage: 2500VAC (channel-to-channel, channel-to-bus) -

Signal Response Time: <5 ms (input change to CPU update) -

Operating Temperature: -25°C to +60°C -

Humidity Range: 5% to 95% non-condensing -

Power Supply: 24V DC (from AC500 rack backplane, 18-32V DC range) -

Power Consumption: 1.2W (typical, all channels active) -

Diagnostics: Channel short/open circuit, power monitoring, communication heartbeat -

Hot Swap Support: Yes (plug-and-play replacement without system shutdown) -

Dimensions: 25mm x 128mm x 115mm (width x height x depth, fits AC500 I/O rack) -

Weight: 0.18kg -

Certifications: CE, UL, cULus, RoHS

ABB 1SAP240000R0001 DI524

-

Automotive Assembly: Connects 16 proximity switches on a conveyor line to monitor part presence. 2500VAC isolation prevents EMI from robotic arms from causing false triggers. -

Water Treatment: Acquires signals from 12 level switches (dry contact) and 4 valve position sensors (solid-state) across lift stations. Data sent to SCADA via AC500 CPU. -

Chemical Batch Reactor: Monitors 8 agitator overload switches (dry contact) and 8 temperature limit switches (solid-state). Hot-swap functionality allows maintenance during planned turnarounds.