Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

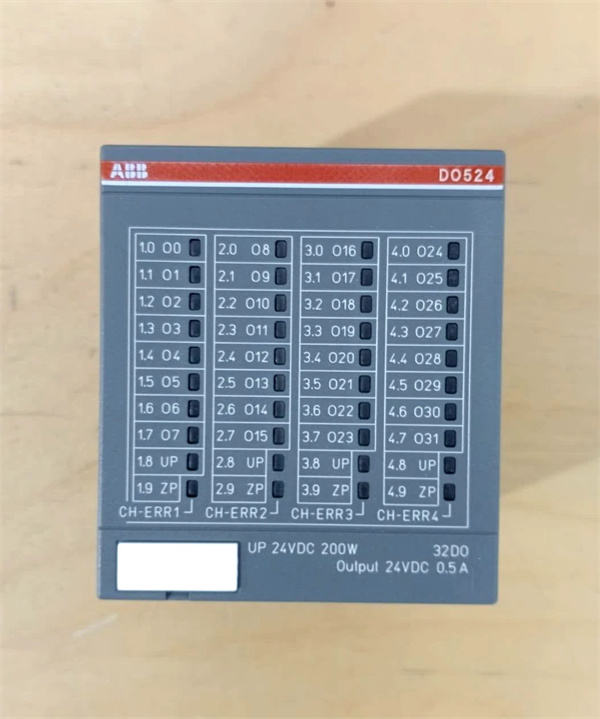

| Product Model | DO524 A3 1SAP240700R0001 |

| Manufacturer | ABB |

| Product Category | Digital output module |

| Number of Output Channels | 16 isolated digital outputs |

| Output Voltage | 24 V DC |

| Maximum Output Current per Channel | 0.5 A |

| Total Maximum Output Current | 8 A |

| Response Time | ≤ 1 ms |

| Isolation | 2.5 kV AC between channels and backplane |

| Operating Temperature Range | -25°C to +60°C |

| Protection Class | IP20 (when installed in control cabinet) |

| Dimensions (W×H×D) | 100 mm × 160 mm × 80 mm (approx.) |

| Weight | 0.3 kg (approx.) |

| Compatibility | ABB AC800M PLC system, DSQC652 robot I/O module (for integrated automation) |

| Mounting | DIN rail mounting (35 mm) |

| Certification | CE, UL, IECEx |

ABB DO524 A3 1SAP240700R0001

Product Introduction

The ABB DO524 A3 1SAP240700R0001 is a high-performance digital output module designed to serve as a reliable interface in industrial automation systems, particularly well-suited for integration with ABB’s AC800M PLC system. This module excels at converting digital control signals from the central processor into actionable commands for a wide array of industrial actuators, ensuring precise and timely operation in complex automation environments.

Equipped with 16 isolated output channels, the ABB DO524 A3 1SAP240700R0001 can drive devices such as relays, small solenoid valves, indicator lights, and low-power contactors. When combined with robot I/O modules like the ABB DSQC652 in integrated manufacturing systems, it enables seamless communication between the PLC and robotic workcells—allowing the PLC to control robotic peripherals (e.g., gripper actuators, conveyor triggers) via the module’s outputs, while receiving status feedback through associated input modules. This interoperability makes it a valuable component in industries ranging from automotive assembly to electronics manufacturing.

Core Advantages and Technical Highlights

High Channel Density

With 16 output channels in a compact form factor, the ABB DO524 A3 1SAP240700R0001 offers exceptional channel density, making it ideal for applications where space in the control cabinet is limited. For example, in a printed circuit board (PCB) assembly line, a single module can control multiple pick-and-place machine peripherals—such as feeder motors, vision system illuminators, and conveyor diverters—reducing the number of modules needed and simplifying cabinet layout.

Robust Isolation and Protection

The module features 2.5 kV AC isolation between channels and the backplane, providing robust protection against electromagnetic interference (EMI) and ground loops. This isolation ensures stable operation even in noisy industrial environments, such as near welding robots or large motors. Additionally, each channel includes short-circuit protection, preventing damage to the module if a connected actuator or wire develops a fault. When paired with the ABB DSQC652 in a robotic workcell, this protection ensures that electrical issues in the robot’s peripheral devices do not affect the main control system.

Fast and Reliable Response

With a response time of ≤ 1 ms, the ABB DO524 A3 1SAP240700R0001 ensures that control signals are executed with minimal delay, critical for time-sensitive applications. In a high-speed packaging line, for instance, the module can quickly activate a sealing jaw after a product is detected, ensuring precise synchronization with the conveyor speed. This rapid response, combined with consistent output performance, helps maintain high production throughput and product quality.

ABB DO524 A3 1SAP240700R0001

Typical Application Scenarios

In an automotive component manufacturing plant, the ABB DO524 A3 1SAP240700R0001 is integrated into the PLC system controlling a robotic assembly station. The module’s outputs are connected to solenoid valves that actuate grippers, part positioners, and fixture clamps. When the ABB DSQC652 robot I/O module sends a signal indicating the robot is ready to pick a part, the PLC triggers the appropriate output on the ABB DO524 A3 1SAP240700R0001 to open the gripper. After the part is placed, the module deactivates the valve to close the gripper, ensuring secure handling. The module’s isolation prevents electrical noise from the robot’s motors from interfering with valve control, maintaining consistent part placement accuracy.

In a food and beverage bottling line, the module controls label applicators, bottle diverters, and cap tighteners. It receives signals from the PLC, which processes data from sensors monitoring bottle position and fill levels. When a bottle is detected as underfilled, the PLC sends a command to the ABB DO524 A3 1SAP240700R0001, which activates a diverter valve to redirect the bottle to a reject conveyor. The module’s ability to operate in temperatures up to 60°C ensures reliable performance even in warm environments near pasteurization equipment. Integration with temperature relays like the ABB TR104 (via the PLC) adds an extra layer of safety—if a cap tightener overheats, the module can shut it down to prevent product contamination.

In a warehouse automation system, the ABB DO524 A3 1SAP240700R0001 controls the motors of shuttle cars and conveyor sections in an automated storage and retrieval system (AS/RS). The PLC uses the module to start/stop motors, activate brakes, and trigger position locks based on signals from barcode scanners and proximity sensors. When a shuttle car reaches a target location, the module deactivates the motor and engages the brake, ensuring precise positioning of the car. The module’s high channel count allows it to control multiple conveyors and shuttles from a single unit, simplifying system architecture.

Related Model Recommendations

- ABB DI524 1SAP240000R0001: A digital input module that complements the ABB DO524 A3 1SAP240700R0001, collecting signals from sensors to provide input data for the control system.

- ABB DSQC652: A robot I/O module that works with the ABB DO524 A3 1SAP240700R0001in integrated robotic systems, enabling communication between the PLC and robot peripherals.

- ABB AC800M PLC: The central processor module that integrates with the ABB DO524 A3 1SAP240700R0001to process data and issue control commands, forming the core of the automation system.

- ABB TB820V2 3BSE013208R0001: A terminal base that simplifies wiring between the ABB DO524 A3 1SAP240700R0001and field devices, reducing installation time and improving reliability.

- ABB RVAR-5612: A voltage regulator module that provides stable 24 V DC power to the ABB DO524 A3 1SAP240700R0001, ensuring consistent output performance.

- ABB 1SFB527068D7084: A safety relay module that, when paired with the ABB DO524 A3 1SAP240700R0001, can shut down critical outputs in emergency situations, enhancing workplace safety.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing the ABB DO524 A3 1SAP240700R0001, ensure the control cabinet is clean, dry, and free from excessive vibration. The ambient temperature should be within -25°C to +60°C, with relative humidity below 95% (non-condensing). Required tools include a screwdriver (PH2), wire strippers, and a torque wrench (set to 0.5 – 0.7 Nm for terminal connections). Disconnect the power supply to the control system to avoid electrical hazards. Mount the module on a 35 mm DIN rail, ensuring a secure fit to prevent movement. Use shielded twisted-pair cables for output connections, with the shield grounded at both ends, to minimize EMI. Follow the module’s labeling and system wiring diagram to connect each channel to the corresponding actuator, ensuring correct polarity.

Commissioning Steps

After installation, power on the control system and verify that the ABB DO524 A3 1SAP240700R0001 is recognized by the AC800M PLC using ABB’s configuration software. Configure the module’s parameters, such as output signal inversion (if needed), via the PLC software. Test each output channel by sending a control signal from the PLC and confirming that the connected actuator (e.g., a relay) activates correctly. Use a multimeter to measure the output voltage, ensuring it is within the specified 24 V DC range. Verify the module’s status LEDs—each channel has a green LED that illuminates when the output is active, providing visual confirmation of operation. If integrated with the ABB DSQC652, test the communication between the PLC and robot system by triggering a joint output (e.g., robot gripper activation via the module) and confirming proper synchronization.

Maintenance Suggestions

For daily maintenance of the ABB DO524 A3 1SAP240700R0001, inspect the module and connections for dust accumulation and clean with a soft, dry cloth or compressed air (low pressure). Check terminal screws periodically to ensure they are tight; loose connections can cause intermittent output issues or overheating. Monitor the module’s temperature during operation to ensure it remains within the specified range. If a channel fails to activate, first check the connected actuator and wiring; if they are functional, use the PLC’s diagnostic tools to check for module faults. Replace the module with an ABB-approved spare if necessary. It is recommended to perform a full functional test of all channels quarterly, including testing integration with associated devices like the ABB DSQC652, to ensure reliable operation.

Service and Guarantee Commitment

The ABB DO524 A3 1SAP240700R0001 comes with a 2-year warranty, covering defects in materials and workmanship under normal operating conditions. During the warranty period, ABB will repair or replace faulty modules free of charge. Our global technical support team is available 24/7 to provide assistance with installation, configuration, and troubleshooting via phone, email, or online chat.

We offer comprehensive online resources, including user manuals, wiring diagrams, and firmware updates, to support efficient system deployment. Optional service contracts provide on-site technical support, training sessions, and priority response times, ensuring optimal performance of the ABB DO524 A3 1SAP240700R0001 throughout its lifecycle. ABB’s commitment to quality ensures that this module delivers reliable performance, supporting the seamless operation of your industrial automation systems.