Description

Detailed Parameter Table

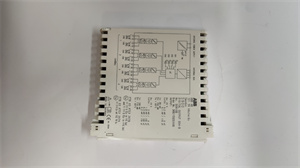

| Parameter Name | Parameter Value |

| Product model | DO910 |

| Manufacturer | ABB |

| Product category | Digital output module |

| Compatible systems | ABB AC800M controller, S800 I/O system |

| Number of channels | 16 digital output channels |

| Output type | Relay outputs (changeover contacts) |

| Rated switching voltage | 250 V AC / 30 V DC |

| Rated switching current | 5 A (resistive load) |

| Maximum switching power | 1250 VA (AC) / 150 W (DC) |

| Operating voltage | 24 V DC ±10% |

| Power consumption | ≤ 6 W |

| Operating temperature | -25°C to +70°C |

| Storage temperature | -40°C to +85°C |

| Dimensions (W×H×D) | 22 mm × 105 mm × 115 mm (approx.) |

| Weight | Approximately 0.3 kg |

| Installation method | DIN rail mounting (35 mm standard rail) via terminal base (e.g., TB820V2) |

| Protection class | IP20 |

| Compliance | CE, UL, IEC 61131-2 |

| Diagnostic features | LED indicators for power, channel status, and faults; short-circuit and overload protection |

| Connection type | Plug-in interface with terminal base (TB820V2) |

| Isolation | Channel-to-channel: 2.5 kV AC; Channel-to-bus: 2.5 kV AC |

ABB DO910

Product introduction

The DO910 is a high-performance digital output module from ABB, designed to convert digital control signals from the AC800M controller into switching actions for field devices in industrial automation systems. As a key component of the S800 I/O family, it serves as the “execution interface” of the automation system, enabling the controller to activate or deactivate devices such as motors, valves, solenoids, and alarms.

This module integrates seamlessly with ABB’s AC800M controller and relies on terminal bases like the TB820V2 for secure wiring connections to field devices. With 16 relay output channels, each featuring changeover contacts (NO/NC), the DO910 offers exceptional flexibility for controlling both AC and DC loads, making it suitable for a wide range of industrial applications—from simple on/off control of pumps in water treatment plants to activating complex machinery in manufacturing lines.

Built to withstand harsh industrial environments, the DO910 features robust channel-to-channel isolation and wide temperature tolerance, ensuring reliable operation in settings like chemical plants, power stations, and automotive factories. Its plug-in design simplifies installation and maintenance, while advanced diagnostics minimize downtime by quickly identifying issues such as short circuits or overloads. Unlike the AI810 3BSE008516R1 (which focuses on analog input measurement), the DO910 specializes in digital control, providing a critical counterpart in complete automation systems.

Core advantages and technical highlights

High channel density

The DO910 offers 16 digital output channels in a compact 22 mm width, maximizing space utilization in control cabinets. In a manufacturing facility with numerous actuators to control, this high density reduces the number of modules needed, simplifying wiring and lowering overall system costs. Compared to modules with fewer channels, the DO910 minimizes cabinet footprint while maintaining easy access to individual channels for troubleshooting.

Versatile load compatibility

With relay outputs rated for 250 V AC and 30 V DC, the DO910 can control a wide range of industrial devices, including AC motors, DC solenoids, and heating elements. Each channel’s changeover contacts (NO/NC) provide flexibility in circuit design—for example, using the normally closed contact to trigger an alarm if power to a pump is lost, while the normally open contact controls the pump itself. This versatility surpasses that of solid-state output modules, which are often limited to specific voltage types.

Robust protection features

The DO910 incorporates comprehensive protection mechanisms, including short-circuit and overload protection on each channel. If a connected device develops a short circuit, the module’s internal protection prevents damage to the channel, and the corresponding LED indicator turns red to alert technicians. This fault tolerance is crucial in critical applications like oil refineries, where a single channel failure should not disrupt the entire system.

Enhanced diagnostics

Equipped with LED indicators for each channel, the DO910 provides real-time visibility into output status: a green LED indicates an active output (contact closed), while a red LED signals a fault. This simplifies troubleshooting—technicians can quickly identify whether a problem lies in the module, wiring, or field device without specialized tools. The module also transmits detailed fault data to the AC800M controller, enabling predictive maintenance and reducing downtime.

ABB DO910

Typical application scenarios

In a food and beverage processing plant, the DO910 acts as the primary control interface for packaging line equipment. Connected to the TB820V2 terminal base, it receives digital commands from the AC800M controller and activates:

- Conveyor belt motors (240 V AC) via normally open contacts

- Solenoid valves (24 V DC) for filling nozzles

- Alarm buzzers (120 V AC) for fault conditions

- Heaters in shrink-wrapping machines (230 V AC)

The DO910‘s 16 channels control all these devices from a single module, streamlining cabinet design. When paired with the AI810 3BSE008516R1 analog input module, which monitors sensor data (e.g., bottle position, temperature), the system forms a closed-loop control network—adjusting outputs based on real-time process conditions to ensure packaging quality.

In a water treatment plant, the DO910 integrates with the CI810B 3BSE020520R Profibus module to control valves and pumps based on signals from the SCADA system. The AI810 3BSE008516R1 measures water levels and pressure, sending data to the AC800M controller, which then uses the DO910 to open or close valves as needed, maintaining optimal flow rates.

Related model recommendations

- DO820 3BSE008546R1: An 8-channel digital output module with solid-state outputs, ideal for high-speed switching applications where relay wear is a concern.

- AI810 3BSE008516R1: An analog input module that, when paired with the DO910, creates a complete control loop—e.g., measuring tank level with the AI810and activating a drain valve via the DO910.

- TB820V2: A terminal base that provides secure wiring connections for the DO910, enabling plug-and-play installation and easy maintenance.

- DI810 3BSE008539R1: A digital input module that complements the DO910by monitoring the status of field devices (e.g., limit switches) and sending feedback to the controller.

- 3BHE009017R0102: A power supply module that delivers stable 24 V DC to the DO910and connected terminal base, ensuring reliable operation.

- CI801: A Modbus communication module that transmits control signals from the AC800M controller to the DO910in systems with legacy Modbus infrastructure.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the DO910, ensure the control cabinet is clean, dry, and free from conductive debris. The ambient temperature must be within -25°C to +70°C, with relative humidity ≤95% (non-condensing). Required tools include a screwdriver, wire strippers, and a multimeter.

Mount the TB820V2 terminal base on a 35 mm DIN rail, then plug the DO910 into the base until it clicks into place. For field device connections:

- Use appropriate gauge wires (0.5-2.5 mm²) based on load current

- Separate high-voltage wiring (e.g., 240 V AC motor lines) from low-voltage control signals to minimize interference

- Connect loads to either normally open (NO) or normally closed (NC) contacts based on circuit design

Connect the 24 V DC power supply (from 3BHE009017R0102) to the terminal base, verifying polarity. Configure channel behavior (e.g., fail-safe state) via the AC800M controller software before powering on.

Maintenance suggestions

For daily maintenance, check the DO910‘s LEDs: a steady green power LED and channel LEDs indicate normal operation, with green LEDs lighting when outputs are active. A red channel LED signals a fault (e.g., short circuit or overload)—refer to the user manual for specific codes.

Inspect terminal connections quarterly for corrosion, looseness, or overheating (discolored insulation), which can cause contact resistance. Clean the module with compressed air to remove dust; avoid liquids that may damage electronics.

Test relay contacts annually using a multimeter to check for wear—look for increased resistance or intermittent continuity, which indicate the need for replacement. If a channel fails, swap loads between channels to isolate the issue—if the fault follows the load, replace the field device; otherwise, replace the DO910 with an ABB-approved spare.

Service and guarantee commitment

The DO910 is backed by ABB’s 3-year warranty, covering defects in materials and workmanship under normal operating conditions. During the warranty period, ABB will repair or replace faulty modules at no cost, minimizing operational disruptions.

ABB’s technical support team provides 24/7 assistance for installation, configuration, and troubleshooting, including guidance on integrating the DO910 with the AC800M controller, AI810 3BSE008516R1 input module, and TB820V2 terminal base. We offer detailed wiring diagrams and application notes to ensure optimal performance.

Extended service contracts are available, including on-site testing, priority support, and software updates. ABB’s global network ensures fast delivery of replacement modules, reducing downtime in critical applications. Trust the DO910 to deliver reliable digital control, backed by ABB’s expertise in industrial automation.