Description

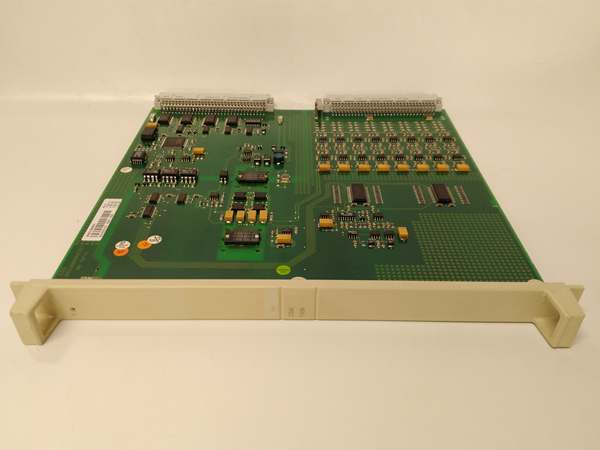

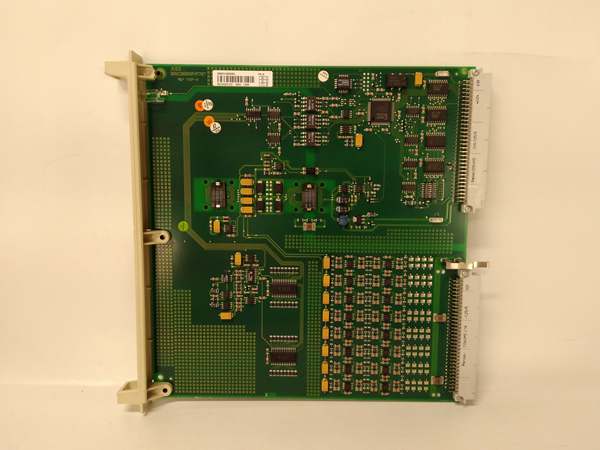

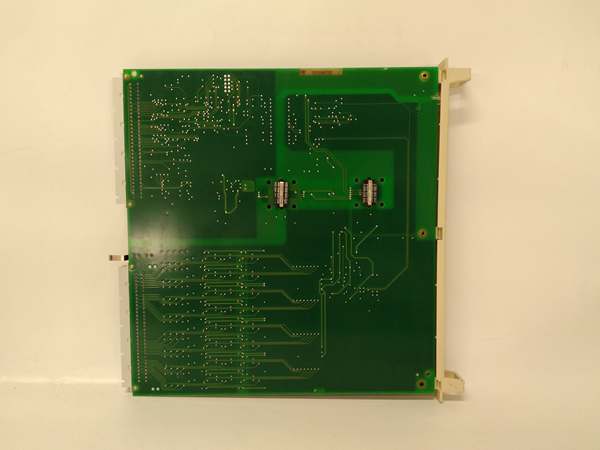

DSAI133: Product Overview

The ABB DSAI133 is a 32-channel analog input module designed for ABB’s Advant Master Process Control System, a legacy DCS platform widely used in industries like power generation, oil & gas, and chemical processing. As a critical I/O component, it enables precise acquisition of analog signals from field devices (e.g., pressure transmitters, temperature sensors, flow meters) and transmits the data to the Advant Master controller for process monitoring and control.

Role in Automation Systems:

In Advant Master architectures, the DSAI133 acts as an interface between field devices and the central controller. It performs three primary functions:

-

Signal Conditioning: Amplifies and filters weak analog signals from sensors to ensure accurate transmission.

-

Analog-to-Digital Conversion (ADC): Converts continuous analog signals (e.g., 4–20 mA) into 16-bit digital data for the controller.

-

Isolation: Provides galvanic isolation between channels and the system bus to protect the controller from electrical noise and voltage spikes.

Core Functionality:

-

32-Channel Capacity: Supports up to 32 analog inputs, reducing the number of modules required and simplifying cabinet layout.

-

Flexible Signal Compatibility: Accepts multiple signal types (voltage/current) and ranges, adapting to diverse field devices without additional hardware.

-

High Precision: 16-bit resolution and ±0.05% accuracy ensure reliable measurement of critical process variables (e.g., turbine temperature, pipeline pressure).

Platform Benefits (Advant Master System):

The DSAI133 leverages ABB’s legacy of reliability in industrial automation. Key benefits include:

-

Backward Compatibility: Compatible with earlier Advant Master components, enabling phased modernization of existing facilities.

-

Scalability: Supports expansion with additional I/O modules to accommodate growing operational needs.

-

Diagnostic Capabilities: Built-in status LEDs and fault logging simplify troubleshooting, reducing mean time to repair (MTTR).

ABB DSAI133

Technical Specifications

Model Number: DSAI133

Manufacturer: ABB

Product Type: Analog Input Module

-

Channels: 32 (single-ended/differential)

-

Signal Types: 0–10 V, ±10 V, 0–20 mA, 4–20 mA

-

Resolution: 16-bit

-

Accuracy: ±0.05% (full scale)

-

Input Impedance: 250 Ω (current), 10 MΩ (voltage)

-

Isolation: 1500 V AC (channel-to-system)

-

Communication: ABB Advant Master System Bus

-

Power Supply: 24 V DC (±10%)

-

Operating Temperature: -20°C to +70°C (-4°F to 158°F)

-

Storage Temperature: -40°C to +85°C (-40°F to 185°F)

-

Humidity: 5% to 95% non-condensing

-

Dimensions (W×H×D): 324 mm × 234 mm × 9 mm (12.76 in × 9.21 in × 0.35 in)

-

Weight: 0.4 kg (0.88 lbs)

-

Certifications: CE, UL, RoHS (exempt per EU Directive 2011/65/EU)

Core Features & Customer Value

1. High-Precision Signal Acquisition:

The DSAI133’s 16-bit resolution and ±0.05% accuracy ensure that critical process variables (e.g., boiler pressure, reactor temperature) are measured with precision. This accuracy is essential for maintaining product quality in chemical processing or complying with environmental regulations in power generation.

2. Flexible Signal Compatibility:

With support for multiple signal types (voltage/current) and ranges, the DSAI133 adapts to diverse field devices without requiring additional signal conditioning hardware. This flexibility reduces installation costs and simplifies inventory management for engineers.

3. Robust Isolation:

The module’s 1500 V AC galvanic isolation protects the Advant Master controller from electrical noise and voltage spikes generated by field devices (e.g., motors, solenoids). This ensures reliable data transmission and reduces the risk of controller damage.

4. Easy Integration:

Designed specifically for ABB’s Advant Master System, the DSAI133 installs in standard I/O chassis and communicates with the controller via the System Bus. This plug-and-play compatibility reduces setup time and effort for engineers.

ABB DSAI133

Typical Applications

The ABB DSAI133 is widely used in industries relying on ABB’s Advant Master Process Control System:

-

Power Generation:

-

Monitors turbine temperature, pressure, and flow using 4–20 mA sensors.

-

Example: In a coal-fired power plant, the DSAI133 acquires temperature signals from a turbine and transmits data to the Advant Master controller, which adjusts fuel flow to maintain optimal efficiency.

-

-

Oil & Gas:

-

Interfaces with pipeline pressure transmitters and flow meters to monitor crude oil/gas transportation.

-

Example: In an offshore oil rig, the DSAI133 collects pressure data from a subsea sensor and sends it to the controller, enabling operators to adjust valve positions and prevent overpressure.

-

-

Chemical Processing:

-

Measures pH, temperature, and concentration in chemical reactors using analog sensors.

-

Example: In a petrochemical refinery, the DSAI133 acquires pH signals from a reactor and transmits data to the controller, which adjusts the flow of neutralizing agents to maintain optimal reaction conditions.

-