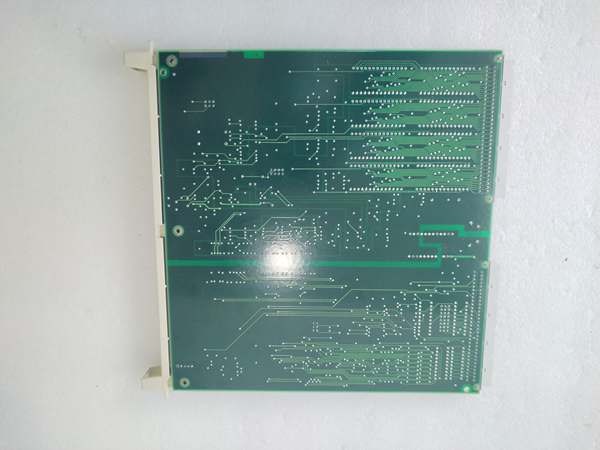

Description

ABB DSAI146

-

Model Number: DSAI146 -

Manufacturer: ABB -

Product Type: Analog Input Module -

Number of Channels: 16 (independent, software-configurable) -

Input Types: 4-20mA (2/4-wire), 0-10V DC, RTD (PT100, 2/3/4-wire) -

Resolution: 16-bit ADC (65536 steps for precise measurement) -

Accuracy: ±0.1% of reading (4-20mA/0-10V), ±0.2% of reading (RTD) -

Electrical Isolation: Channel-to-channel and channel-to-bus (1500Vrms) -

Power Supply: 24V DC (±10%, drawn from Symphony Plus I/O rack backplane) -

Operating Temperature: -25°C to +60°C -

Storage Temperature: -40°C to +85°C -

Common Mode Rejection Ratio (CMRR): >90dB at 50/60Hz -

Communication Interface: S800 I/O bus (proprietary, high-speed serial) -

Dimensions: 198mm x 25mm x 120mm (WxHxD, S800 I/O form factor) -

Weight: 0.28kg

ABB DSAI146