Description

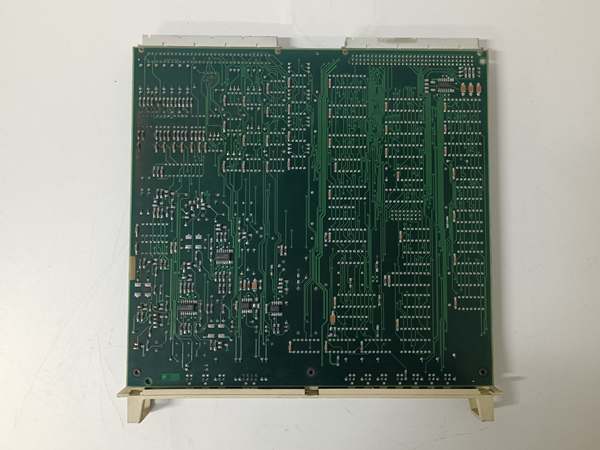

ABB DSBC172 57310001-KD

- ••

Model Number: DSBC172 - ••

Manufacturer Part Number: 57310001-KD - ••

Manufacturer: ABB Robotics - ••

Product Type: Bus Computer Module - ••

Compatible Controller: S4C+ Robot Controller - ••

Function: Backplane communication management and bus arbitration - ••

Communication Interface: Proprietary backplane protocol - ••

Data Transfer Rate: High-speed synchronous communication - ••

Module Support: Interfaces with main computer, axis computer, I/O modules - ••

Power Requirement: +5VDC and +24VDC from controller backplane - ••

Operating Temperature: 0°C to 55°C (controller environment) - ••

Physical Interface: Eurocard format with custom backplane connector - ••

Status Indicators: LED indicators for power and communication status ABB DSBC172 57310001-KD