Description

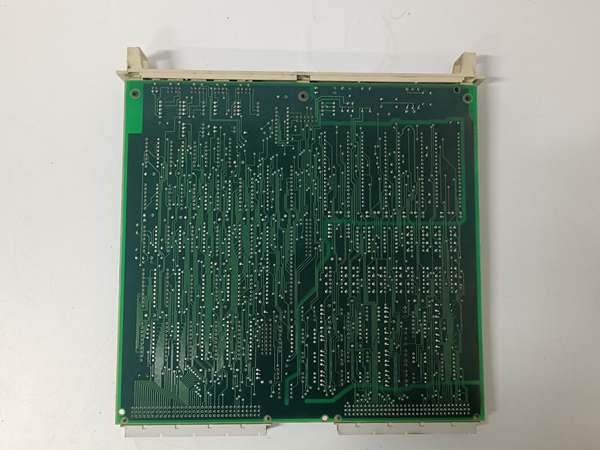

DSCA114 57510001-AA

- ••

Model Number: DSCA114 - ••

Manufacturer Part Number: 57510001-AA - ••

Manufacturer: ABB Robotics - ••

Product Type: Main Computer Board - ••

Compatible Controller: S4C+ Robot Controller - ••

Function: Central processing and system management - ••

Processor: High-performance RISC processor - ••

Memory: System RAM for operating system and user programs - ••

Operating System: RobotWare - ••

Communication Interfaces: Backplane connection to all controller modules - ••

External Interfaces: Support for teach pendant, network communication modules - ••

Power Requirement: +5VDC from controller backplane - ••

Operating Temperature: 0°C to 55°C (controller environment) - ••

Physical Interface: Eurocard format with custom backplane connector DSCA114 57510001-AA