Description

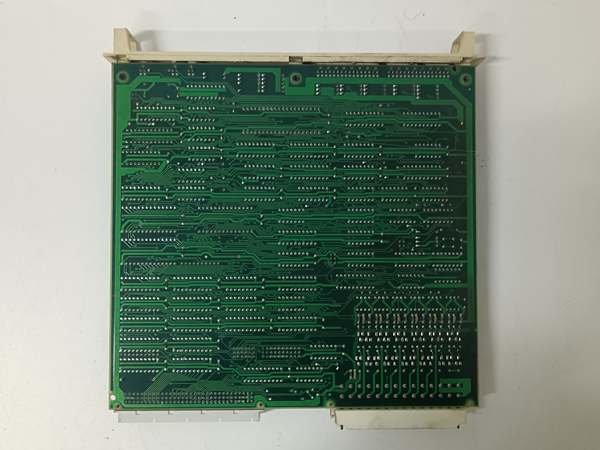

ABB DSCS131 57310001-LM

- ••

Model Number: DSCS131 - ••

Manufacturer Part Number: 57310001-LM - ••

Manufacturer: ABB Robotics - ••

Product Type: Servo Control Board - ••

Compatible Controller: S4C+ Robot Controller - ••

Function: Servo control and drive interface - ••

Axis Control: Supports standard 6-axis robots - ••

Feedback Interface: Resolver or encoder input - ••

Communication: Backplane connection to axis computer and drive modules - ••

Update Rate: High-speed servo update (typically 1kHz or higher) - ••

Power Requirement: +5VDC and +24VDC from controller backplane - ••

Operating Temperature: 0°C to 55°C (controller environment) - ••

Physical Interface: Eurocard format with custom connector ABB DSCS131 57310001-LM