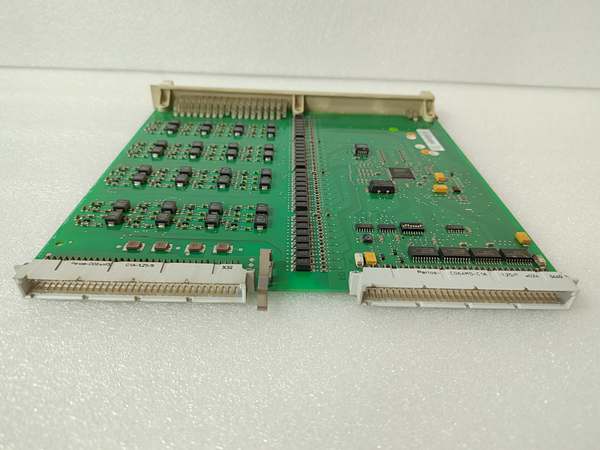

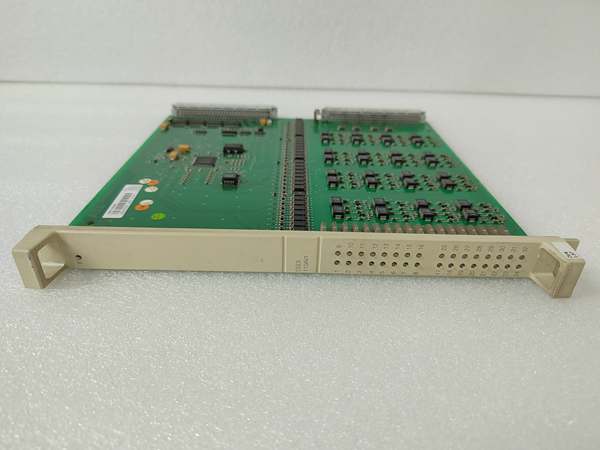

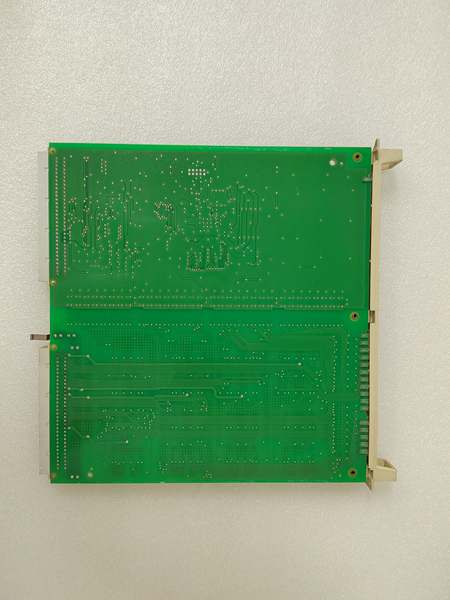

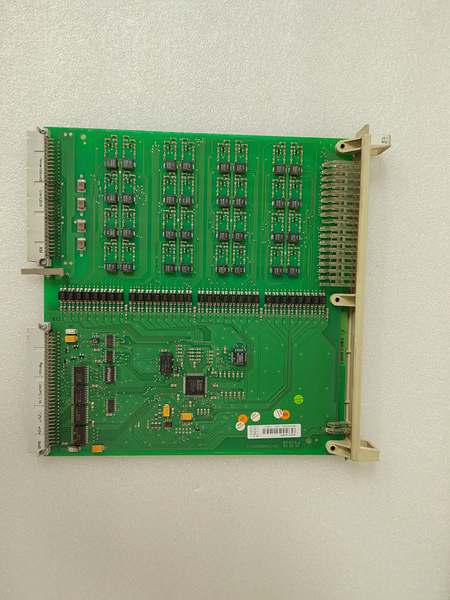

Description

ABB DSDI110A

-

Model Number: DSDI110A -

Manufacturer: ABB -

Product Type: Digital Input Module -

Number of Channels: 16 (independent, software-configurable) -

Input Type: Dry contact (normally open/closed), transistor (NPN/PNP sinking/sourcing) -

Input Voltage: 24VDC (±10% tolerance, 5mA per channel typical) -

Electrical Isolation: Channel-to-channel and channel-to-bus (1500Vrms) -

Power Supply: 24V DC (±10%, drawn from Symphony Plus I/O rack backplane) -

Operating Temperature: -25°C to +60°C -

Storage Temperature: -40°C to +85°C -

Protection Rating: IP20 (panel-mount, finger-safe terminals) -

Signal Filtering: Configurable debounce time (0-100ms) -

Communication Interface: S800 I/O bus (proprietary, high-speed serial) -

Dimensions: 198mm x 25mm x 120mm (WxHxD, S800 I/O form factor) -

Weight: 0.26kg

ABB DSDI110A