Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | DSDP140B |

| Manufacturer | ABB |

| Product category | Digital input module |

| Number of channels | 16 (isolated) |

| Input type | 24 V DC, sinking/sourcing (configurable) |

| Input voltage range | 15-30 V DC |

| Response time | 1 ms (standard), 0.1 ms (fast mode) |

| Isolation | Channel-to-channel: 500 V AC; Channel-to-backplane: 2.5 kV AC |

| Maximum current per channel | 7 mA @ 24 V DC |

| Power supply | 24 V DC ±10% (from backplane) |

| Power consumption | Max 3 W |

| Operating temperature | -25°C to 60°C |

| Protection rating | IP20 |

| Mounting type | Backplane mount (compatible with GRBTU 3BSE013175R1) |

| Dimensions | 100mm × 80mm × 60mm |

| Certifications | CE, UL, ATEX, IEC 61131-2 |

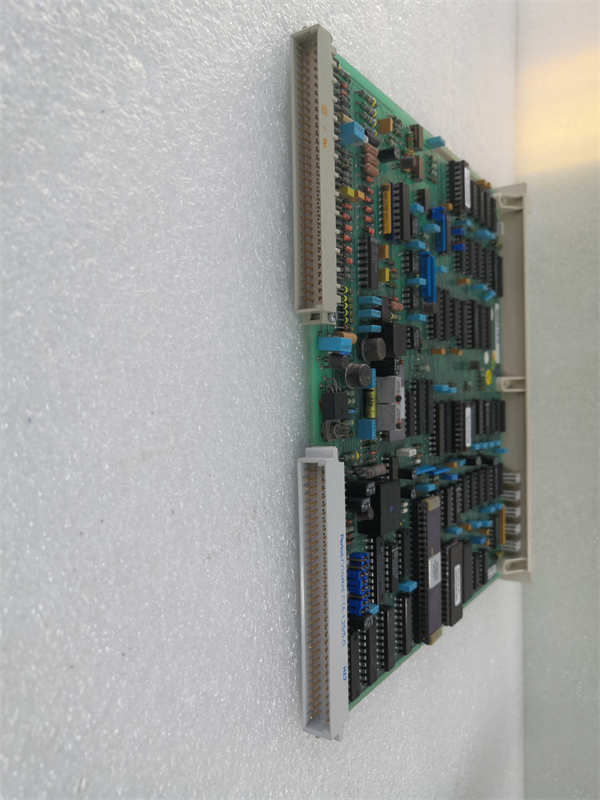

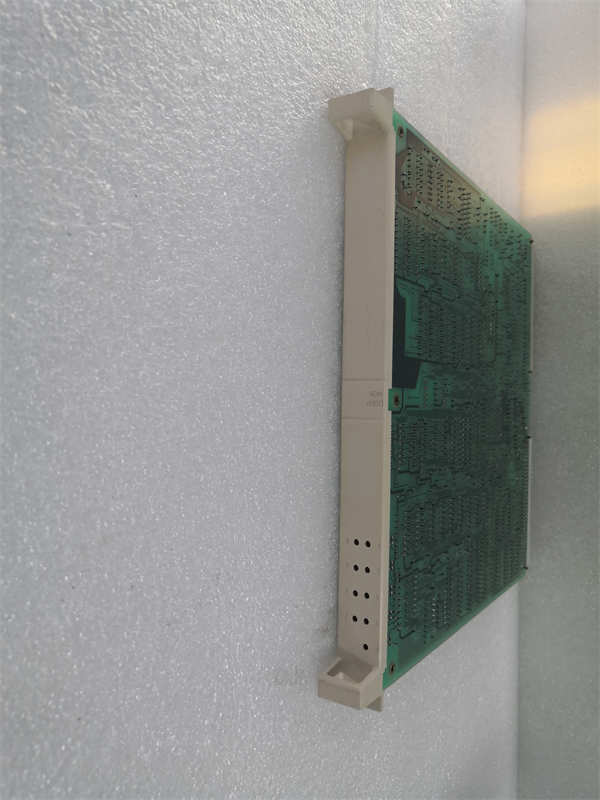

ABB DSDP140B

Product introduction

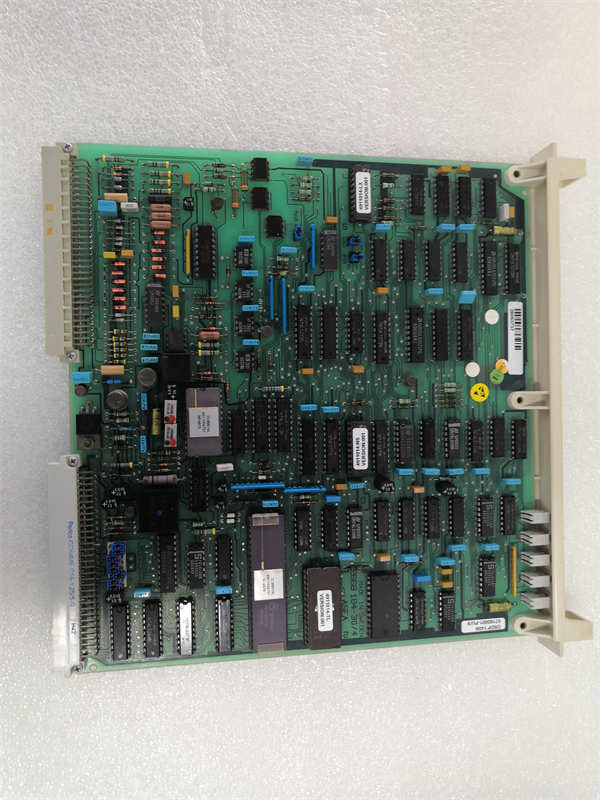

The DSDP140B is a high-performance 16-channel digital input module from ABB, designed to interface with industrial sensors, switches, and other discrete devices in automation systems. As a key component in ABB’s distributed I/O portfolio, DSDP140B converts digital signals from field devices into data readable by control systems, seamlessly integrating with communication bus terminal units like the GRBTU 3BSE013175R1 and PLCs such as the 500CPU05 1MRB150081R1/E.

This module offers configurable input modes (sinking/sourcing) and fast response times, making it suitable for diverse applications—from monitoring limit switches in conveyor systems to capturing high-speed events in packaging machinery. Unlike basic digital input cards, DSDP140B provides robust channel isolation and wide operating margins, ensuring reliable operation in noisy industrial environments. Whether deployed in automotive plants, food processing facilities, or water treatment systems, DSDP140B delivers accurate, real-time digital data to support critical control decisions.

Core advantages and technical highlights

High-density channel configuration: With 16 isolated channels in a compact form factor, DSDP140B maximizes I/O density, reducing the number of modules needed in control cabinets. In a logistics warehouse, this allows monitoring of 16 conveyor belt sensors (e.g., presence detectors, end stops) using a single module, saving 40% of backplane space compared to 8-channel alternatives.

Flexible input configuration: Each channel of DSDP140B can be individually set to sinking or sourcing mode via software, eliminating the need for hardware modifications when connecting different types of field devices. For example, in a machine tool application, it can interface with both NPN (sinking) proximity sensors and PNP (sourcing) limit switches without additional adapters, simplifying system design and reducing inventory costs.

Fast response for time-critical applications: DSDP140B supports a configurable response time of 1 ms (standard) or 0.1 ms (fast mode), enabling it to capture high-speed events such as bottle jams in filling lines or emergency stop signals. In a high-speed packaging machine, the 0.1 ms mode ensures the control system receives jam alerts within microseconds, triggering immediate shutdowns to prevent equipment damage.

Robust noise immunity: With 500 V AC channel-to-channel isolation and 2.5 kV AC isolation from the backplane, DSDP140B rejects electromagnetic interference (EMI) and ground loops common in industrial environments. In a steel mill, this isolation ensures reliable signal detection despite nearby high-voltage motors and welders, reducing false triggers that could disrupt production.

Seamless system integration: DSDP140B integrates seamlessly with ABB’s GRBTU 3BSE013175R1 bus terminal unit, enabling data transmission over PROFINET or PROFIBUS networks to the central PLC. Its hot-swappable design allows replacement without powering down the system—a critical feature in continuous processes like chemical production, where unplanned downtime is costly.

Typical application scenarios

In an automotive assembly line, DSDP140B modules monitor the status of robotic welders, including clamp position sensors, torch trigger switches, and safety interlocks. Connected to a GRBTU 3BSE013175R1 via backplane, they transmit real-time data to the 500CPU05 PLC, which coordinates welding sequences. The module’s fast response time (0.1 ms) ensures the PLC detects torch misalignment instantly, pausing the process to prevent defective welds. Its rugged design withstands the mechanical vibrations and electrical noise of the production environment.

In a water treatment plant, DSDP140B units monitor valve position switches, pump status contacts, and level float switches across filtration and disinfection stages. Configured in sinking mode to match the plant’s NPN sensors, they send status data to the SCADA system via GRBTU 3BSE013175R1’s PROFINET interface. The module’s wide operating temperature range (-25°C to 60°C) ensures reliable performance in outdoor pump stations, while its channel isolation prevents ground loops from affecting measurement accuracy.

ABB DSDP140B

Related model recommendations

DSDO140B: ABB’s 16-channel digital output module that complements DSDP140B for controlling actuators and valves.

DSDP180B: A 8-channel high-current variant of DSDP140B (20 mA per channel) for powering inductive sensors.

GRBTU 3BSE013175R1: ABB’s bus terminal unit that integrates DSDP140B into PROFINET/PROFIBUS networks.

500CPU05 1MRB150081R1/E: ABB’s PLC that processes digital input data from DSDP140B.

UAD154A 3BHE026866R0101: ABB’s analog input module that, when paired with DSDP140B, provides mixed-signal monitoring.

TB857: ABB’s surge protection terminal block that safeguards DSDP140B from voltage transients in industrial environments.

HMI60: ABB’s touchscreen panel that visualizes DSDP140B input status, enabling operators to monitor field device health.

Installation, commissioning and maintenance instructions

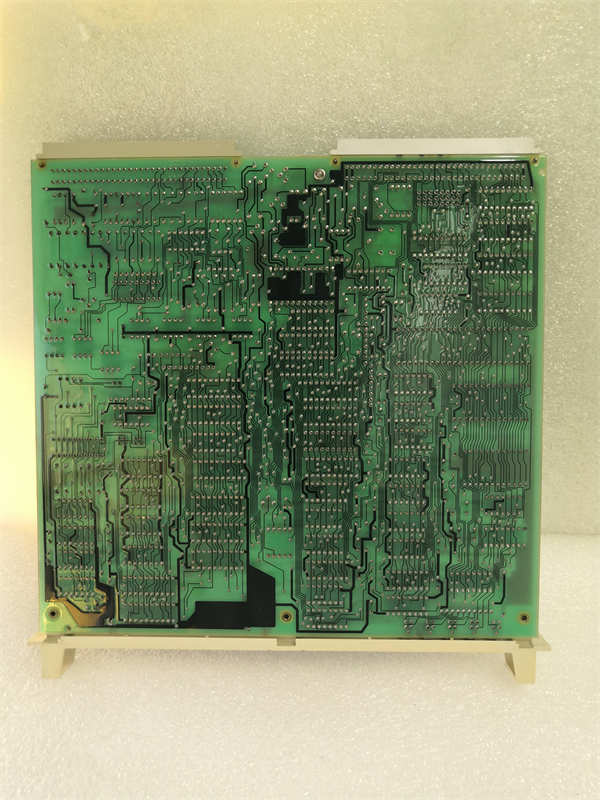

Installation preparation: Insert DSDP140B into the designated slot of a compatible backplane (e.g., connected to GRBTU 3BSE013175R1), ensuring proper alignment with the connector. Secure with the front-panel screw (torque to 0.5 Nm). Connect field devices using 0.5-1 mm² shielded cable, with each channel wired to its corresponding terminal (signal and common). For sinking mode, connect the field device’s common to 24 V DC; for sourcing mode, connect to 0 V DC. Required tools include a screwdriver, wire strippers, and a multimeter for continuity checks. Power off the backplane during installation.

Configuration steps: Use ABB’s Control Builder M software to configure DSDP140B’s input mode (sinking/sourcing) and response time (standard/fast) for each channel. Map channels to the PLC’s address space via the GRBTU 3BSE013175R1 bus unit. Perform a signal test by activating each field device (e.g., pressing a limit switch) and verifying the corresponding channel status in the PLC. Save configurations to ensure retention after power cycles.

Maintenance suggestions: Inspect DSDP140B quarterly for loose terminal connections and dust accumulation, cleaning with compressed air if necessary. Check LED indicators (per-channel status) to confirm proper operation—steady green indicates active input, while no light indicates an open circuit. Test response time annually using a signal generator, ensuring it meets application requirements. If channels fail to respond or exhibit erratic behavior, check field device wiring and power before replacing the module. Use only ABB-certified replacements to maintain system compatibility.

Service and guarantee commitment

DSDP140B comes with a 5-year warranty from installation, covering manufacturing defects and ensuring compliance with published performance specifications. ABB guarantees technical support response within 4 hours for critical applications, with on-site service available in 72 hours for qualified industrial facilities. The module includes free access to configuration software tools. Extended service contracts offer annual preventive maintenance, calibration verification, and priority support, ensuring DSDP140B maintains reliable operation throughout its 15-year design lifespan. Customers receive dedicated online resources, including wiring diagrams, configuration guides, and troubleshooting manuals specific to this model.