Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | DSMB-01C |

| Manufacturer | ABB |

| Product category | Motor control and protection module |

| Rated supply voltage | 24 – 240 V AC/DC |

| Rated current range | 0.1 – 125 A (adjustable) |

| Overload protection accuracy | ±5% |

| Short – circuit protection response time | < 10 ms |

| Communication interface | Modbus RTU, Profibus DP (optional) |

| Operating temperature | -25°C to +60°C |

| Dimensions (W×H×D) | 100 mm × 150 mm × 80 mm |

| Mounting method | DIN – rail mounting |

| Protection class | IP20 (when installed in a suitable enclosure) |

| Diagnostic functions | Overload, short – circuit, under – voltage, phase – loss diagnosis |

| Control outputs | Relay outputs for motor start/stop and alarm indication |

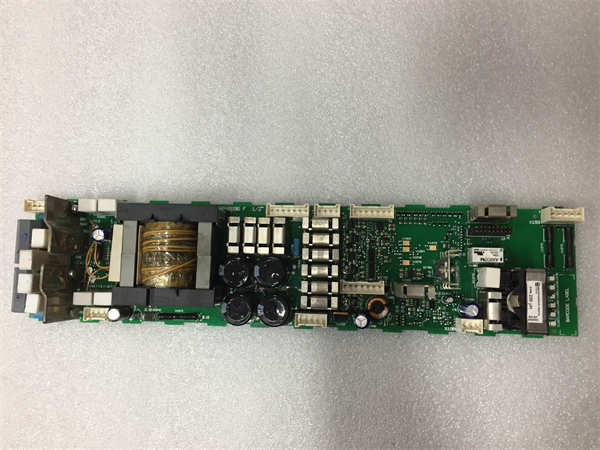

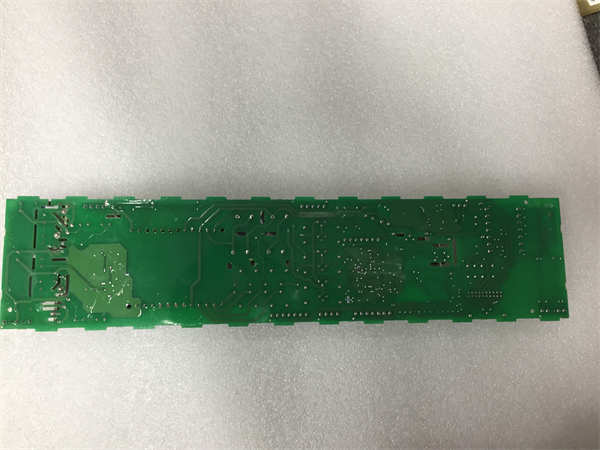

ABB DSMB-01C

Product introduction

The ABB DSMB – 01C is a high – performance motor control and protection module designed to ensure the reliable operation of motors in industrial applications. As part of ABB’s comprehensive range of motor control solutions, it combines advanced protection features with efficient control capabilities.

This module offers precise motor protection against various electrical faults. For instance, its overload protection mechanism continuously monitors the motor current, and in case of an overload, it can take prompt action to prevent motor damage. With a wide rated current range from 0.1 – 125 A, it can be easily adjusted to suit different motor sizes. The DSMB – 01C also provides reliable short – circuit protection with a response time of less than 10 ms, safeguarding the motor and associated equipment from catastrophic failures.

In an industrial automation system, the DSMB – 01C plays a crucial role. It can be easily integrated into motor control centers (MCCs) or distributed control systems (DCS). Its communication interfaces, such as Modbus RTU and optional Profibus DP, enable seamless data exchange with other components in the system. This allows for remote monitoring and control of the motor, enhancing the overall efficiency of the automation process.

Core advantages and technical highlights

High – accuracy protection

The DSMB – 01C offers overload protection with an accuracy of ±5%. This precise protection ensures that motors are not unnecessarily tripped during normal load fluctuations, while also providing timely protection when an actual overload occurs. In a manufacturing plant where motors are constantly operating under varying loads, this accuracy helps in minimizing production downtime due to false tripping.

Fast response short – circuit protection

With a short – circuit protection response time of less than 10 ms, the module can quickly isolate the faulty motor from the power supply. In applications where short – circuits can cause significant damage to equipment and disrupt production, such as in a chemical processing plant, this rapid response can prevent major accidents and reduce repair costs.

Flexible communication options

The availability of Modbus RTU and optional Profibus DP communication interfaces makes the DSMB – 01C highly compatible with different industrial communication networks. In a large – scale industrial complex with a mix of different devices and systems, it can easily communicate with programmable logic controllers (PLCs), human – machine interfaces (HMIs), and other control components, facilitating centralized monitoring and control.

Typical application scenarios

In manufacturing plants, the DSMB – 01C is widely used to protect and control motors that drive conveyor belts, pumps, and compressors. For example, in a food and beverage factory, conveyor belt motors are constantly moving products along the production line. The DSMB – 01C can monitor the motor current and detect any signs of overload caused by jams or excessive product load. If an overload is detected, it can either send an alarm or automatically stop the motor to prevent damage.

In water treatment plants, pumps are crucial for the proper functioning of the facility. The DSMB – 01C can protect these pumps from electrical faults. For instance, in case of a phase – loss situation, which can cause uneven loading on the pump motor and lead to premature failure, the module can quickly detect the problem and take corrective action, such as shutting down the motor to avoid further damage.

In power generation plants, compressors are used to supply air for combustion processes. The DSMB – 01C can ensure the reliable operation of these compressors by providing protection against short – circuits and overloads. In a gas – fired power plant, if a compressor motor experiences a short – circuit due to insulation breakdown, the module’s fast – acting short – circuit protection will isolate the motor, preventing damage to the expensive compressor equipment and ensuring the continuous operation of the power plant.

ABB DSMB-01C

Related model recommendations

DSMB – 02C: An upgraded version of DSMB – 01C with additional communication protocols like Ethernet/IP, suitable for modern industrial Ethernet – based automation systems where high – speed data transfer is required.

DSMA – 01C: A more basic motor protection module from ABB, which has similar protection functions as DSMB – 01C but with a more limited current range (0.1 – 50 A), ideal for smaller – scale applications with less demanding motor requirements.

ACS580 – M – 01A: ABB’s variable – speed drive that can be paired with DSMB – 01C in applications where motor speed control is also needed. The DSMB – 01C provides protection, while the ACS580 – M – 01A adjusts the motor speed according to the process requirements.

SACE Emax 2: A circuit breaker that can be used in combination with DSMB – 01C in high – current applications. The SACE Emax 2 provides overall circuit protection, and the DSMB – 01C focuses on motor – specific protection and control.

AFE580: ABB’s active front – end module that can be integrated with DSMB – 01C in systems where power quality improvement and motor protection are both important. The AFE580 helps in reducing harmonics and improving power factor, while the DSMB – 01C protects the motor.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the DSMB – 01C, ensure that the installation environment is clean, dry, and free from excessive dust and humidity. The ambient temperature should be within the specified range of – 25°C to +60°C. Use a DIN – rail suitable for the module’s size and securely mount it. When connecting power cables and communication wires, make sure to follow the wiring diagrams provided in the user manual. Use appropriate tools such as wire strippers and crimping tools to ensure proper connections. Also, verify that the supply voltage matches the rated voltage of the module.

Maintenance suggestions: Regularly inspect the DSMB – 01C for any signs of physical damage, such as cracks or loose connections. Check the LED indicators on the module to monitor its operating status. If an alarm is indicated, refer to the user manual to identify the fault cause. Periodically test the protection functions using a suitable test equipment to ensure that the overload and short – circuit protection are working correctly. In case of a fault, replace the faulty components with genuine ABB spare parts. Backup the module’s configuration data regularly to avoid losing important settings in case of a module failure.

Service and guarantee commitment

The ABB DSMB – 01C comes with a standard 3 – year warranty against manufacturing defects. ABB’s global service network provides comprehensive technical support. Customers can access online resources, including user manuals, technical documentation, and software updates. In case of any technical issues, ABB’s experts are available to provide remote troubleshooting or on – site support. ABB also offers preventive maintenance services to ensure the long – term reliable operation of the DSMB – 01C. With a vast inventory of spare parts, ABB can quickly supply replacement parts, minimizing downtime. ABB’s commitment to quality and customer satisfaction ensures that the DSMB – 01C will meet the highest performance standards throughout its service life.