Description

DSMD 113: Product Overview

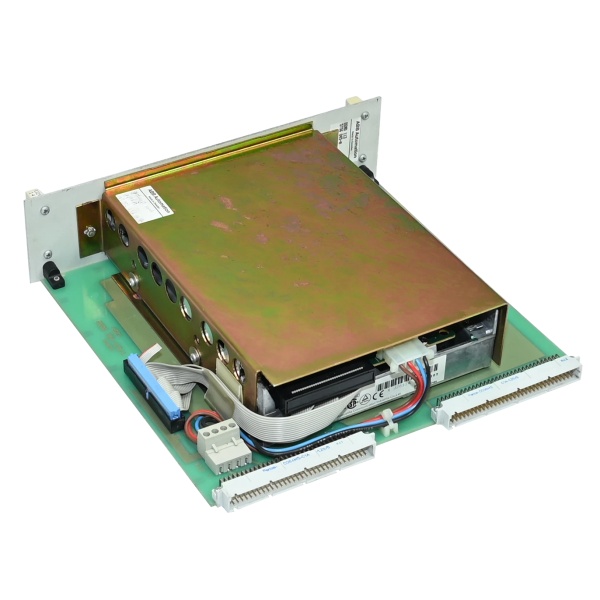

The ABB DSMD 113 (part number: 5736045-N) is an industrial control module designed for integration into ABB’s robotic systems. As a spare part, it plays a vital role in maintaining the operational reliability of ABB robots used in industries such as automotive manufacturing, aerospace, and general automation.

Role in Automation Systems:

Positioned as a support module in ABB’s robotic ecosystem, the DSMD 113 interfaces with the robot’s central controller (e.g., IRC5 or Omnicore) to handle specific tasks:

-

I/O Signal Processing: Acquires analog/digital signals from field devices (e.g., sensors, actuators) and transmits them to the controller for real-time decision-making.

-

Display Processing: Drives local displays (e.g., HMI panels) to provide operators with real-time process data (e.g., robot status, error messages).

-

Communication: Acts as a bridge between the robot controller and external systems (e.g., SCADA, MES) via industrial protocols (e.g., Profibus, Ethernet/IP).

Core Functionality:

While the exact technical specifications of the DSMD 113 are not publicly disclosed (due to its status as a spare part), its design aligns with ABB’s commitment to reliability and compatibility in industrial automation. Key features inferred from supplier listings include:

-

Compact Design: Fits seamlessly into ABB robot control cabinets, minimizing space requirements.

-

Robust Construction: Built with industrial-grade components to withstand harsh environments (e.g., vibration, temperature fluctuations).

-

Plug-and-Play Compatibility: Designed to integrate with existing ABB robot systems without requiring extensive reconfiguration.

Platform Benefits (ABB Robotics):

The DSMD 113 leverages ABB’s expertise in industrial robotics, offering:

-

Minimal Downtime: As a genuine ABB spare part, it ensures quick replacement of faulty modules, reducing robot downtime.

-

Scalability: Adapts to evolving automation needs (e.g., adding new sensors or displays) without replacing the entire control system.

-

Diagnostic Support: Compatible with ABB’s robot diagnostics tools (e.g., RobotStudio), enabling quick troubleshooting.

ABB DSMD 113

Technical Specifications

Model Number: DSMD 113

Part Number: 5736045-N

Manufacturer: ABB

Product Type: Industrial Control Module

-

Compatibility: ABB industrial robots (IRB series)

-

Functionality: I/O signal processing, display processing, or communication (exact function varies by application)

-

Form Factor: Compact (dimensions not publicly available)

-

Weight: Lightweight (suitable for cabinet installation)

-

Certifications: CE, UL (inferred from ABB’s industrial product standards)

Core Features & Customer Value

1. Reliable Spare Part Support:

As a genuine ABB spare part, the DSMD 113 ensures compatibility and performance parity with original components. This reduces the risk of integration issues and ensures that ABB robots operate at peak efficiency.

2. Flexible Functionality:

The module’s ability to handle I/O signals, display data, or communicate with external systems makes it a versatile solution for various robotic applications. For example, in an automotive assembly line, the DSMD 113 can process signals from welding sensors and display real-time status on an HMI panel.

3. Compact & Easy to Install:

The DSMD 113’s compact design allows for easy installation in ABB robot control cabinets, even in space-constrained environments. This minimizes downtime during maintenance or upgrades.

4. Cost-Effective Maintenance:

Investing in genuine ABB spare parts like the DSMD 113 reduces the total cost of ownership by extending the lifespan of ABB robots. This avoids the need for premature replacements and ensures that the robotic system operates reliably for years to come.

ABB DSMD 113

Typical Applications

The ABB DSMD 113 is widely used in industries that rely on ABB robots for process automation:

-

Automotive Manufacturing:

-

Processes signals from welding sensors and displays real-time status on an HMI panel.

-

Example: In a car factory, the DSMD 113 acquires signals from a welding robot’s sensors and transmits them to the central controller, which adjusts the welding parameters for consistent quality.

-

-

Aerospace:

-

Drives displays for robotic assembly systems, providing operators with real-time data on component placement.

-

Example: In an aerospace manufacturing plant, the DSMD 113 drives a display that shows the position of a robotic arm as it places a component onto an aircraft wing.

-

-

General Automation:

-

Acts as a communication bridge between ABB robots and external SCADA systems, enabling remote monitoring and control.

-

Example: In a packaging plant, the DSMD 113 transmits data from a robotic palletizer to a SCADA system, which monitors the palletizing process and alerts operators to any issues.

-