Description

Detailed parameter table

| Parameter name | Parameter value |

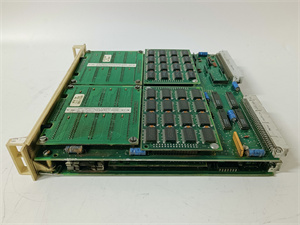

| Product model | DSPC174 3BSE005461R1 |

| Manufacturer | ABB |

| Product category | Digital Signal Processing Control Module |

| Weight | 0.25 kg |

| Dimensions (LxWxH) | 15 cm x 10 cm x 5 cm |

| Input channels | 8 |

| Output channels | 8 |

| Operating voltage | 24 V DC |

| Operating temperature range | – 20°C to + 60°C |

| Communication protocols | Modbus, Profibus |

| Processor type | High – performance DSP chip |

| Data processing speed | High – speed data processing for real – time applications |

ABB DSPC174 3BSE005461R1

Product introduction

The ABB DSPC174 3BSE005461R1 is a high – performance digital signal processing control module, designed to meet the complex demands of industrial automation scenarios. As part of ABB’s extensive range of industrial control products, it plays a crucial role in enhancing the precision and reliability of digital signal processing within industrial systems.

This module is engineered to seamlessly integrate into various industrial control setups, whether it’s a Programmable Logic Controller (PLC) system, a Distributed Control System (DCS), or a Supervisory Control and Data Acquisition (SCADA) system. It serves as a key component that enables the efficient handling of digital signals, ensuring that industrial processes are executed with utmost accuracy. By processing input signals from sensors and devices, the DSPC174 3BSE005461R1 can generate appropriate control signals to actuators, thereby maintaining the smooth operation of industrial machinery and production lines.

Core advantages and technical highlights

Advanced processing capabilities: Equipped with a high – performance DSP chip, the ABB DSPC174 3BSE005461R1 offers fast and accurate signal processing. This allows it to handle complex algorithms and real – time data with ease. In high – speed manufacturing processes, such as automotive assembly lines, it can quickly analyze sensor data related to component positioning and robot arm movements, enabling precise control to avoid errors and improve production efficiency.

Robust design: Built to withstand the rigors of industrial environments, this module has a durable construction. With an operating temperature range of – 20°C to + 60°C, it can function reliably in harsh conditions, whether it’s a cold storage facility or a hot and humid factory floor. Its ability to endure temperature variations and environmental stress makes it a reliable choice for long – term industrial applications.

Flexible communication: Supporting popular communication protocols like Modbus and Profibus, the DSPC174 3BSE005461R1 can easily interface with other devices in an industrial network. This compatibility enables seamless integration into existing automation systems, regardless of the make or model of other components. A power plant can use this module to communicate with different types of control devices, ensuring coordinated operation across the entire power generation and distribution infrastructure.

Typical application scenarios

Industrial automation production lines: In a food and beverage bottling plant, the ABB DSPC174 3BSE005461R1 is used to control the filling and capping processes. It receives input signals from sensors that detect the presence of bottles, the level of liquid in the filling machines, and the torque of the capping mechanisms. Based on this data, it adjusts the speed of conveyors, the flow rate of the filling nozzles, and the capping force, ensuring consistent product quality and high – speed production.

Power generation and distribution: In a power substation, this module is employed to monitor and control electrical parameters. It processes signals from current and voltage sensors, calculates power factors, and controls circuit breakers and capacitor banks. By doing so, it helps maintain the stability of the power grid, ensuring efficient power distribution and protecting electrical equipment from overloading or voltage fluctuations.

Manufacturing machinery control: A textile factory uses the DSPC174 3BSE005461R1 to manage the operation of weaving machines. It analyzes signals related to thread tension, loom speed, and fabric quality, and then adjusts the machine settings in real – time. This results in better – quality fabric production and reduced downtime due to machine malfunctions.

ABB DSPC174 3BSE005461R1

Related model recommendations

DSPC170: A predecessor model in the same series, it has similar basic functions but with a slightly lower processing speed. It can be a cost – effective alternative for less demanding applications, such as small – scale manufacturing plants where the complexity of signal processing tasks is not as high.

DSPC180: An upgraded version with enhanced processing power and additional I/O channels. It is suitable for large – scale industrial projects that require more extensive data handling and control capabilities, like integrated steel mills with numerous sensors and actuators.

PM864: A control module from ABB that can be paired with the DSPC174 3BSE005461R1 in complex DCS setups. The PM864 focuses on overall process management, while the DSPC174 handles the detailed digital signal processing, working together to optimize industrial processes.

CI854: A communication interface module that can expand the communication options of the DSPC174 3BSE005461R1. It adds support for protocols like IEC 61850, which is beneficial for applications in the smart grid or modern industrial networks that require advanced communication features.

AI810: An analog input module that can be used in conjunction with the DSPC174 when there is a need to interface with more analog sensors in an industrial process. For example, in a chemical plant where multiple analog sensors are used to monitor temperature, pressure, and pH levels, the AI810 can feed this analog data to the DSPC174 for processing.

Installation, commissioning and maintenance instructions

Installation preparation: Before installation, ensure that the environment meets the temperature and humidity requirements specified for the ABB DSPC174 3BSE005461R1 ( – 20°C to + 60°C temperature and normal industrial humidity levels). Mount the module in a suitable control cabinet, making sure to follow the proper grounding procedures. Use appropriate tools, such as a screwdriver with the correct torque setting, to securely fasten the module to the mounting brackets. When connecting the power supply, double – check the voltage and polarity to avoid any damage to the module. Also, ensure that the communication cables are properly shielded and terminated to prevent signal interference.

Maintenance suggestions: Regularly inspect the module for any signs of physical damage, such as cracks or loose connections. Clean the module periodically to remove dust and debris that could affect its performance. Monitor the operating temperature of the module, as overheating can lead to reduced lifespan and performance degradation. In case of communication failures, first check the integrity of the communication cables and the settings of the connected devices. If the module experiences abnormal behavior, refer to the troubleshooting guide provided by ABB. Spare parts such as replacement capacitors and connectors should be kept on hand for quick replacement in case of component failures.

Service and guarantee commitment

ABB offers a comprehensive service and guarantee for the DSPC174 3BSE005461R1. The product comes with a standard 1 – year warranty, during which any manufacturing defects will be covered. ABB’s global technical support team is available 24/7 to provide assistance with installation, commissioning, and troubleshooting. They can offer detailed guidance and solutions to ensure the proper operation of the module. ABB also ensures the long – term availability of spare parts, minimizing downtime in case of component failures. Additionally, customers can access ABB’s online resources for firmware updates and product documentation. This commitment reflects ABB’s confidence in the quality and reliability of the DSPC174 3BSE005461R1 and its dedication to providing a seamless experience for industrial customers.