Description

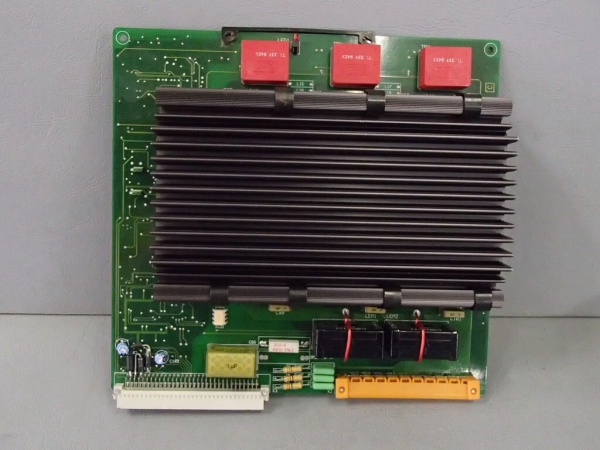

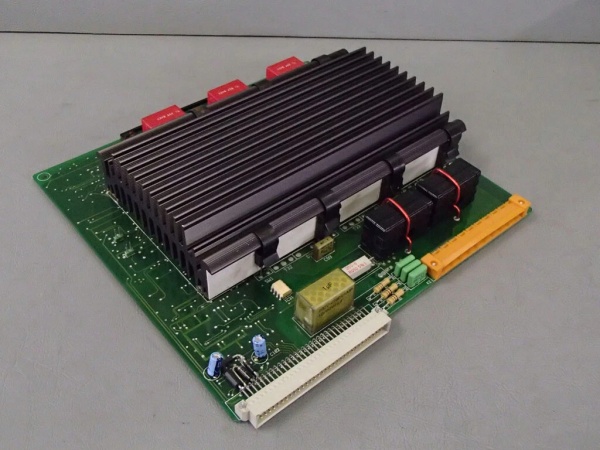

ABB DSQC-236C

DSQC-236C: Product Overview

The ABB DSQC-236C is a compact robot drive control board designed for integration with industrial robotic systems. Positioned as a critical interface in automation architectures, it facilitates real-time communication and control between the robot controller and peripheral devices (e.g., sensors, actuators, servo drives).

Role in Automation Systems:

-

Signal Conversion: Translates analog/digital signals from field devices (e.g., 4–20 mA pressure transmitters, discrete limit switches) into formats compatible with the robot controller.

-

Data Acquisition: Collects process data (e.g., joint torque, positional feedback) for monitoring and closed-loop control.

-

System Integration: Bridges legacy field devices with modern robotic controllers, enabling phased upgrades without full system overhauls.

Core Functionality:

-

Isolated Input/Output Channels: Galvanic isolation (up to 1,500 V AC) protects the controller from electrical noise generated by motors or solenoids.

-

Compact Design: DIN rail-mountable form factor (52 mm × 84 mm × 26 mm) minimizes cabinet space, ideal for retrofits or space-constrained installations.

-

Multi-Protocol Support: Compatible with Modbus RTU and other industrial protocols for seamless integration with third-party devices.

Platform Benefits (ABB Robotics):

-

Legacy Compatibility: Supports ABB’s legacy robotic systems, ensuring continuity for aging infrastructure.

-

Scalability: Modular design allows expansion with additional I/O modules to accommodate growing operational needs.

-

Diagnostic Capabilities: Built-in LED indicators and fault logging simplify troubleshooting, reducing mean time to repair (MTTR).

Technical Specifications

Model Number: DSQC-236C

Manufacturer: ABB

Product Type: Robot Drive Control Board

-

Power Supply: 24 V DC (±10%)

-

Input Channels: 16 configurable digital I/O (sink/source)

-

Output Channels: 16 digital outputs (relay/solid-state)

-

Communication Interfaces:

-

1 × RS-485 (Modbus RTU)

-

1 × CANopen

-

-

Operating Temperature: -20°C to +70°C (-4°F to 158°F)

-

Storage Temperature: -40°C to +85°C (-40°F to 185°F)

-

Humidity: 5% to 95% non-condensing

-

Dimensions (W×H×D): 52 mm × 84 mm × 26 mm (2.05″ × 3.31″ × 1.02″)

-

Weight: 0.04 kg (0.088 lbs)

-

Protection Rating: IP20 (front panel)

-

Certifications: CE, UL, RoHS

ABB DSQC-236C

Core Features & Customer Value

1. Robust Signal Isolation:

The DSQC-236C’s galvanic isolation ensures noise immunity in electrically harsh environments (e.g., motor-driven machinery, high-voltage equipment). This prevents false readings and control system failures, critical for applications like automotive assembly or power generation.

2. Flexible Signal Configuration:

Supports both analog and digital I/O, allowing engineers to adapt the module to diverse field devices (e.g., pressure transmitters, proximity switches). Configurable input ranges (e.g., 0–20 mA, 4–20 mA) eliminate the need for signal conditioning hardware, reducing installation costs.

3. Compact and Modular Design:

The module’s DIN rail-mountable design simplifies installation in control panels, even in retrofitted systems. Its small footprint (52 mm × 84 mm) maximizes cabinet space utilization, a key advantage in upgrades where space is limited.

4. Enhanced Reliability:

-

Component Quality: Industrial-grade components ensure longevity in 24/7 operations.

-

Diagnostic Tools: Built-in fault indicators (e.g., overvoltage, short circuit) enable rapid troubleshooting, minimizing downtime.

Typical Applications

-

Automotive Manufacturing:

-

Controls robotic arms and conveyor systems via digital I/O.

-

Example: In a body shop, the DSQC-236C drives solenoid valves to actuate welding arms based on sensor inputs.

-

-

Power Generation:

-

Interfaces with turbine control systems to regulate cooling valves.

-

Example: In a gas turbine plant, the DSQC-236C converts 4–20 mA temperature signals to Modbus RTU for transmission to the central controller.

-

-

Oil & Gas Pipeline Control:

-

Manages actuator positions for pipeline valves.

-

Example: In a pipeline SCADA system, the DSQC-236C processes 0–10 V pressure signals to adjust valve openings.

-

-

Food Processing:

-

Monitors hygiene sensors and controls CIP (Clean-in-Place) systems.

-

Example: The DSQC-236C acquires 4–20 mA flow signals from pumps and triggers cleaning cycles.

-