Description

DSQC236T: Product Overview

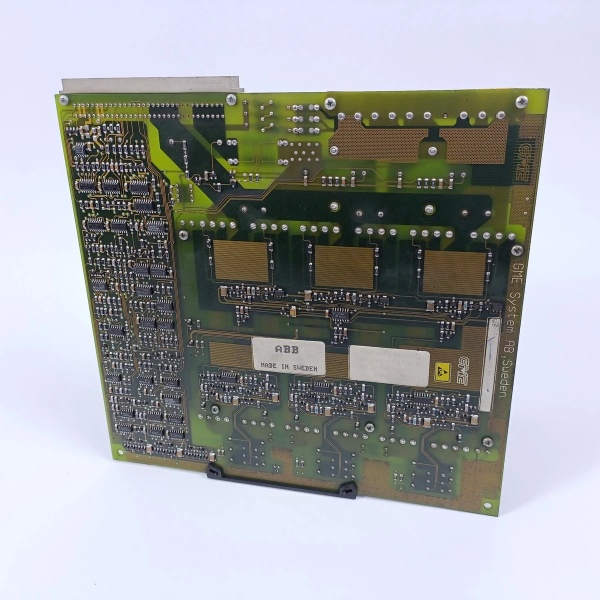

ABB DSQC236T

DSQC236T: Technical Specifications

-

Model Number: DSQC236T -

Manufacturer: ABB -

Product Type: Robot Axis Drive Control Board (Servo Controller) -

Operating Voltage: 24V DC (nominal), ±10% tolerance -

Operating Temperature: -20°C to +60°C (suitable for industrial environments) -

Communication Protocol: EtherCAT (high-speed, real-time industrial Ethernet) -

Axis Control: Supports 1–4 axes (configurable via software) -

Feedback Interface: Encoder (incremental or absolute), analog sensors (e.g., potentiometers) -

Protection Features: Overcurrent, overheating, overvoltage, communication error detection -

Dimensions: Compact (exact dimensions vary by configuration; typically <100mm x 100mm x 50mm) -

Weight: Lightweight (typically <500g) for easy installation

DSQC236T: Core Features & Customer Value

-

High-Precision Motion Control: The DSQC236T uses advanced servo algorithms to achieve micrometer-level accuracy in robot axis movement. This is critical for applications like precision assembly (e.g., electronics manufacturing) or welding (e.g., automotive body construction), where even minor deviations can lead to defects. For example, in a smartphone assembly line, the DSQC236T ensures that robotic arms place components (e.g., chips, screens) with sub-millimeter precision, reducing rework rates by up to 30%. -

Real-Time Feedback and Adjustment: The board continuously monitors feedback from robot axis sensors (e.g., encoders) and adjusts the drive output in real time. This closed-loop control minimizes errors caused by load changes, friction, or mechanical wear. For instance, in a material handling robot, if the load on an axis increases (e.g., picking up a heavy part), the DSQC236T automatically adjusts the motor torque to maintain consistent speed and position, preventing dropped parts or damage to the robot. -

Fault Detection and Prevention: Built-in protection features (e.g., overcurrent, overheating) detect abnormal conditions and trigger alarms or shutdowns to prevent damage to the robot and the board. This reduces downtime and maintenance costs—for example, if a motor overheats due to excessive load, the DSQC236T shuts down the axis and sends a fault signal to the robot controller, allowing maintenance personnel to address the issue before it causes permanent damage. -

Modular and Scalable Design: The DSQC236T supports multiple axis configurations (1–4 axes) and integrates easily with other ABB robot components (e.g., I/O modules, safety systems). This scalability makes it suitable for both small-scale robots (e.g., SCARA robots) and large industrial robots (e.g., articulated robots). For example, a manufacturer can start with a 1-axis DSQC236T for a simple pick-and-place robot and upgrade to a 4-axis configuration as production needs grow. -

Energy Efficiency: The board uses energy-efficient components (e.g., low-power microcontrollers, high-efficiency power supplies) to minimize power consumption. This is important for reducing operating costs in large-scale automation systems—for example, a factory with 10 robots using DSQC236T boards could save thousands of dollars annually in electricity costs. ABB DSQC236T

DSQC236T: Typical Applications

-

Automotive Manufacturing: The DSQC236T is widely used in automotive assembly lines to control robotic arms for tasks like welding, painting, and component installation. For example, in a car body welding line, the board controls 6 axes of a robotic arm to precisely weld chassis components together, ensuring consistent weld quality and reducing cycle times. -

Electronics Manufacturing: In electronics assembly, the DSQC236T controls robotic arms for tasks like placing chips on circuit boards, assembling smartphones, or packaging electronic components. Its high precision ensures that tiny components are placed correctly, reducing defects and improving yield. -

Material Handling: The board is used in material handling robots to control axes for picking up, moving, and placing heavy parts (e.g., engine blocks, steel sheets). Its overload protection prevents damage to the robot when handling large loads. -

Packaging and Palletizing: In packaging lines, the DSQC236T controls robotic arms for tasks like sealing boxes, palletizing products, or labeling packages. Its speed and precision ensure that packaging operations are efficient and consistent.