Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

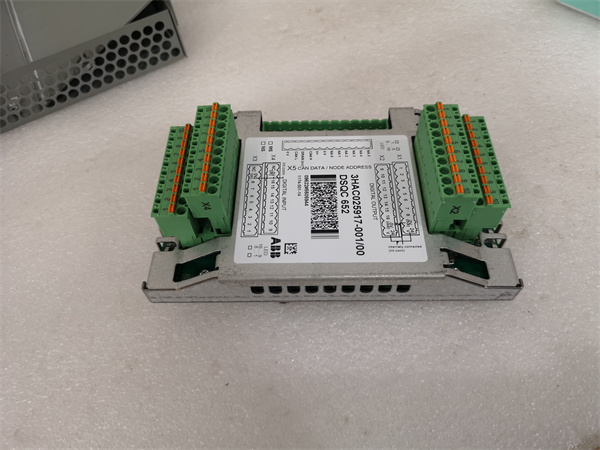

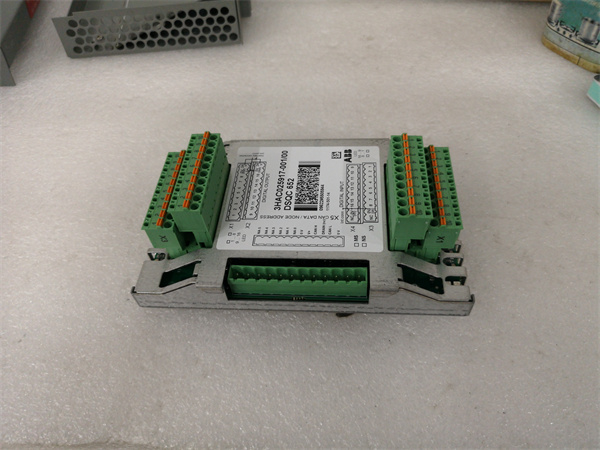

| Product Model | DSQC652 |

| Manufacturer | ABB |

| Product Category | Robot I/O module |

| Number of Digital Inputs | 16 |

| Number of Digital Outputs | 16 |

| Input Voltage | 24 V DC (±10%) |

| Output Voltage | 24 V DC (±10%) |

| Maximum Output Current | 0.5 A per channel, 8 A total |

| Communication Interface | DeviceNet |

| Operating Temperature Range | 0°C to +45°C |

| Protection Class | IP20 (when installed in control cabinet) |

| Dimensions (W×H×D) | 130 mm × 80 mm × 60 mm (approx.) |

| Weight | 0.3 kg (approx.) |

| Compatibility | ABB IRC5 robot controller, TR104 temperature relay (for thermal monitoring) |

| Mounting | DIN rail mounting (35 mm) |

| Certification | CE, UL |

ABB DSQC652

Product Introduction

The ABB DSQC652 is a dedicated I/O module designed for seamless integration with ABB industrial robots, specifically the IRC5 controller series. As a critical interface between the robot controller and external equipment, it enables the exchange of digital signals, allowing the robot to interact with sensors, actuators, and other automation components in the production line.

This module features 16 digital inputs and 16 digital outputs, providing ample connectivity for various field devices. Its DeviceNet communication interface ensures reliable data transmission with the robot controller, facilitating real-time control and monitoring. When paired with the ABB TR104 temperature relay, it can incorporate thermal feedback into the robot’s operation—for example, stopping the robot if a motor or workspace temperature exceeds safe limits, enhancing operational safety.

Core Advantages and Technical Highlights

Seamless Robot Integration

The ABB DSQC652 is specifically engineered to work with ABB IRC5 controllers, ensuring plug-and-play compatibility and eliminating the need for complex configuration. This tight integration allows for low-latency signal transmission, critical for synchronized robot operations. In an automotive welding cell, for instance, the module can receive signals from proximity sensors (via inputs) indicating part presence, then trigger the welding gun (via outputs) with precise timing, ensuring accurate and efficient welds.

Flexible I/O Expansion

With 16 inputs and 16 outputs, the ABB DSQC652 provides sufficient I/O points for most robot workcells, while supporting daisy-chaining of multiple modules for larger systems. This scalability makes it suitable for both simple pick-and-place tasks and complex assembly operations. For example, in an electronics manufacturing plant, a single module can handle signals from conveyor sensors, gripper position switches, and part detectors, while additional modules can control label printers, packaging machines, and quality inspection cameras.

Robust Industrial Design

Built to withstand the rigors of factory environments, the ABB DSQC652 operates reliably within 0°C to +45°C and resists electromagnetic interference from nearby motors and welding equipment. Its outputs are protected against short circuits, preventing damage from wiring errors or actuator faults. When connected to the ABB TR104 temperature relay, it adds an extra layer of protection—if the TR104 detects overheating in the robot’s motor cabinet, the DSQC652 can receive the signal and halt the robot, preventing costly downtime.

Typical Application Scenarios

In a robotic palletizing system, the ABB DSQC652 acts as the central I/O hub. It receives inputs from photoelectric sensors that detect pallet position and box presence, then sends outputs to control conveyor motors, gripper actuators, and pallet release mechanisms. The robot controller uses these signals to coordinate palletizing movements: when a full layer of boxes is detected, the DSQC652 triggers the conveyor to advance the pallet, and the robot adjusts its placement pattern accordingly. Integration with the ABB TR104 ensures the gripper’s pneumatic system remains within safe temperature ranges, preventing component wear.

In a robotic painting cell, the ABB DSQC652 manages safety interlocks and process controls. Inputs from door sensors and light curtains ensure the robot only operates when the cell is closed, while outputs control paint valves, ventilation fans, and drying heaters. If the ABB TR104 detects excessive temperature in the paint heater, it sends a signal to the DSQC652, which shuts off the heater and pauses the robot until the temperature normalizes, ensuring paint quality and preventing fire risks.

In a collaborative robot (cobot) application, the ABB DSQC652 enables safe human-robot interaction. Inputs from force sensors and emergency stop buttons allow the cobot to stop immediately if contact is detected, while outputs control status lights (green for safe operation, red for stop) to alert nearby workers. The module’s low-latency response ensures the cobot reacts instantly to safety signals, meeting strict collaborative safety standards.

ABB DSQC652

Related Model Recommendations

- ABB DSQC651: A compact I/O module with 8 inputs and 8 outputs, suitable for smaller robot workcells with fewer devices.

- ABB IRC5 Controller: The central robot controller that integrates with the ABB DSQC652to process I/O signals and execute robot movements.

- ABB TR104: Temperature relay that works with the DSQC652 to monitor thermal conditions in the robot’s environment or components.

- ABB TU847: Terminal unit that organizes wiring between the DSQC652 and field devices, simplifying installation and maintenance.

- ABB DO820 3BSE008514R1: Digital output module that can extend the DSQC652’s output capacity in large-scale automation systems.

- ABB SPBRC400: Busbar trunking system that provides stable power to the robot controller and DSQC652 module, ensuring consistent operation.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing the ABB DSQC652, ensure the mounting location (robot control cabinet or nearby enclosure) is clean, dry, and free from excessive vibration. The ambient temperature should be within 0°C to +45°C. Required tools include a screwdriver (PH2) and torque wrench (set to 0.5 – 0.7 Nm). Mount the module on a 35 mm DIN rail, ensuring it is close to the IRC5 controller to minimize cable length. Connect the DeviceNet cable to the controller and module, using shielded cable with the shield grounded at both ends. Wire field devices to the input/output terminals, using 0.5 – 1.5 mm² wires and following the module’s labeling for polarity.

Commissioning Steps

After installation, power on the IRC5 controller and verify the ABB DSQC652 is recognized using the robot’s teach pendant. Configure input/output assignments via the controller’s software, mapping each terminal to a specific device (e.g., “Input 1 = Pallet Present Sensor”). Test each input by activating the connected device (e.g., blocking a photoelectric sensor) and confirming the signal is received in the controller’s I/O monitor. Test outputs by triggering them from the teach pendant and verifying the actuator (e.g., a relay) responds. If integrated with the ABB TR104, simulate a high-temperature condition and ensure the DSQC652 receives the signal and triggers the appropriate robot response (e.g., pause).

Maintenance Suggestions

For daily maintenance, inspect the ABB DSQC652 for dust buildup and clean with compressed air (low pressure). Check wiring connections periodically to ensure tightness, especially at terminal blocks and DeviceNet connectors. Monitor the module’s status LEDs—steady green indicates normal operation, while flashing or red LEDs signal faults (refer to the manual for troubleshooting). Test input/output functionality monthly by manually triggering devices and verifying controller feedback. If the module fails to communicate with the IRC5 controller, check the DeviceNet cable and terminators; replace the module if the issue persists. Coordinate maintenance with ABB TR104 checks to ensure thermal monitoring remains reliable.

Service and Guarantee Commitment

The ABB DSQC652 comes with a 1-year warranty, covering defects in materials and workmanship under normal operating conditions. During the warranty period, ABB will repair or replace faulty modules free of charge. Our technical support team, specialized in robot systems, is available 24/7 to assist with installation, configuration, and troubleshooting via phone, email, or on-site service.

We provide detailed integration guides and software tools to simplify setup with IRC5 controllers. Optional service contracts include preventive maintenance visits, training for technicians, and priority access to replacement parts. ABB is committed to ensuring the ABB DSQC652 delivers reliable performance, maximizing uptime for your robot automation system.