Description

Detailed parameter table

| Parameter name | Parameter value |

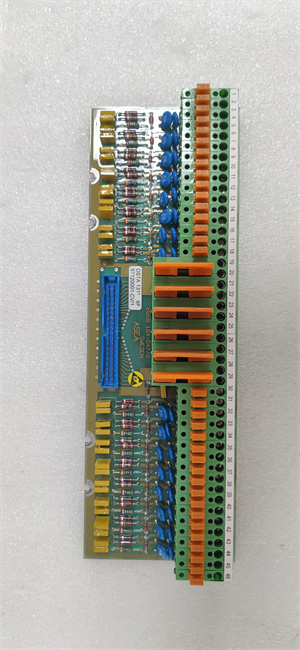

| Product model | DSTA131 |

| Manufacturer | ABB |

| Product category | Digital input module (Advant Controller 400 series) |

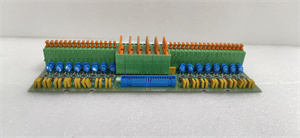

| Number of channels | 16 digital inputs |

| Input type | Dry contacts, 24 V DC (sinking/sourcing) |

| Input voltage range | 15-30 V DC |

| Input current | 3 mA (typical at 24 V DC) |

| Response time | 1 ms (configurable up to 100 ms) |

| Isolation | 2.5 kV AC (channel-to-bus, channel-to-channel) |

| Operating voltage | 24 V DC ±10% |

| Power consumption | ≤ 3 W |

| Operating temperature | 0°C to +60°C |

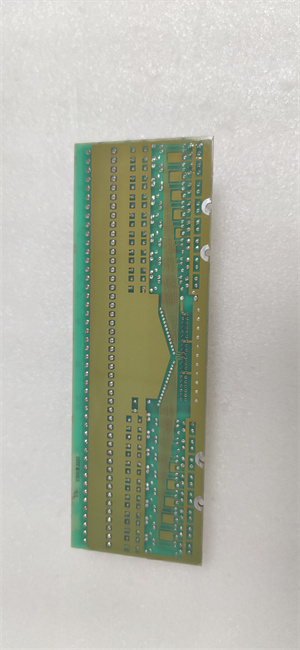

| Dimensions (W×H×D) | 100 mm × 160 mm × 80 mm |

| Installation method | Rack mounting in AC400 controller chassis |

| Diagnostic features | Channel status LEDs, open circuit detection, power failure indication |

| Compliance | IEC 61131-2, CE, UL 508 |

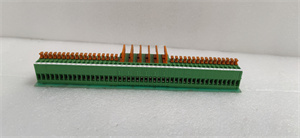

| Compatible systems | ABB Advant Controller 400, MasterPiece 200/1, XVC768115 3BHB007211R115 termination units |

ABB DSTA131

Product introduction

The DSTA131 is a reliable digital input module from ABB, designed specifically for the Advant Controller 400 series to monitor discrete signals in industrial automation systems. As a key component in legacy and mid-range control architectures, it serves as the interface between field devices such as limit switches, pushbuttons, and proximity sensors and the controller, converting physical contact states into digital data for processing.

With 16 channels supporting both dry contacts and 24 V DC signals, DSTA131 offers flexibility for diverse applications, from simple machine monitoring to complex process control. Its robust isolation and diagnostic features ensure stable operation in electrically noisy environments, making it suitable for industries like pulp and paper, metallurgy, and water treatment. Whether integrated with XVC768115 3BHB007211R115 termination units for organized wiring or used in standalone configurations, DSTA131 provides consistent performance, ensuring critical input signals are accurately captured and processed.

Core advantages and technical highlights

Proven reliability

DSTA131 builds on ABB’s legacy of durable industrial components, with a design validated through decades of use in harsh environments. In a steel mill, where temperature fluctuations and electromagnetic interference are common, the module maintains accurate signal detection, ensuring that critical limit switch inputs for rolling mill positioning are reliably transmitted to the controller—preventing costly equipment collisions.

Flexible input handling

The module’s ability to accept both dry contacts and 24 V DC signals eliminates the need for signal converters. In a municipal wastewater plant, this flexibility allows DSTA131 to simultaneously monitor:

- Dry contact float switches (pump station high/low levels)

- 24 V DC proximity sensors (valve position verification)

This versatility simplifies system design and reduces component inventory.

Simplified troubleshooting

Channel status LEDs provide immediate visual feedback, allowing technicians to quickly identify faulty signals without specialized tools. In a food processing plant, a dark LED on DSTA131 immediately indicates a broken wire to a conveyor stop sensor, reducing diagnostic time from hours to minutes and minimizing production downtime.

Typical application scenarios

In a pulp and paper mill’s paper machine control system, DSTA131 monitors key process elements:

- Inputs 1-4: Dry contacts from web break detectors (critical for preventing paper jams)

- Inputs 5-8: 24 V DC signals from roll position sensors

- Inputs 9-16: Limit switches on guide rollers and tensioners

Data from DSTA131 is sent to the Advant Controller 400, which adjusts motor speeds and actuator positions to maintain consistent paper quality. The module’s 2.5 kV isolation protects the controller from electrical noise generated by large motors and drives nearby.

In a chemical batch processing plant with legacy automation, DSTA131 integrates with XVC768115 3BHB007211R115 termination units to monitor:

- Emergency stop button contacts (inputs 1-2)

- Valve open/close limit switches (inputs 3-10)

- agitator overload relays (inputs 11-16)

This configuration allows the plant to maintain reliable operation of existing equipment while enabling gradual modernization, as DSTA131 can communicate with newer HMI systems via the controller’s network interface.

ABB DSTA131

Related model recommendations

- DSTC190: Complementary digital output module that pairs with DSTA131for complete I/O functionality.

- AC400: ABB’s Advant Controller that processes input data from DSTA131.

- XVC768115 3BHB007211R115: Termination unit that organizes field wiring for DSTA131.

- CMA136 3DDE300416: Analog input module that works alongside DSTA131in mixed-signal systems.

- DSQC334: Safety digital input module that complements DSTA131in safety-critical circuits.

- 1SVR011700R0000: 24 V DC power supply for DSTA131and connected field devices.

- TB521: Terminal block that expands wiring capacity when using multiple DSTA131

- DSPA110: Digital signal processor module that enhances DSTA131’s data processing capabilities.

Installation, commissioning and maintenance instructions

Installation preparation

Power off the AC400 controller chassis before installing DSTA131. Insert the module into the designated I/O slot, ensuring proper alignment with the backplane connector, and secure with front-panel screws (torque to 0.5 Nm). Connect field wiring via XVC768115 3BHB007211R115 termination units or directly to the module’s terminals using 0.5-1.5 mm² wires. Separate input wiring from power cables to minimize noise. Verify 24 V DC power supply stability before energizing, ensuring voltage remains within ±10% of nominal. Configure input types (dry contact/voltage) via the controller’s programming software.

Maintenance suggestions

Inspect DSTA131 monthly by verifying green power LED and checking channel LEDs against expected signal states. Clean module connectors quarterly with compressed air to prevent dust buildup. Test open circuit detection annually by disconnecting a known good sensor and confirming the controller registers a fault. If a channel fails, swap the sensor to a spare channel to isolate the issue—replace DSTA131 with an ABB-approved spare if internal faults are confirmed, ensuring the replacement is configured identically to the original module.

Service and guarantee commitment

The DSTA131 is backed by a 2-year warranty, covering defects in materials and workmanship under normal operating conditions. ABB’s legacy systems support team provides technical assistance for integration with both current and discontinued Advant Controller systems, including guidance on pairing with XVC768115 3BHB007211R115 termination units.

Customers receive access to archived manuals and configuration guides for DSTA131. ABB offers repair services for faulty modules, with a focus on extending the lifecycle of legacy systems. With global parts distribution, replacement modules are available to minimize downtime in critical applications. Trust DSTA131 to deliver reliable digital input monitoring, backed by ABB’s commitment to supporting both legacy and modern automation systems.