Description

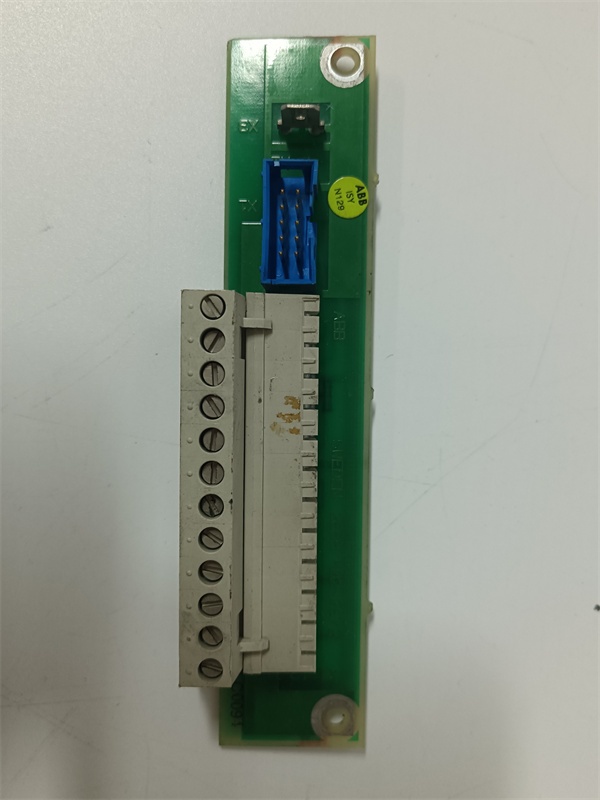

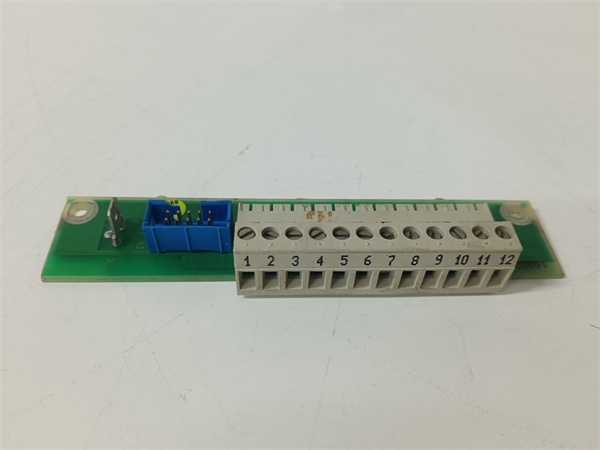

ABB DSTC175

- ••

Model Number: DSTC175 - ••

Manufacturer: ABB (Triconex) - ••

Product Type: Engineering Software License & Media Kit - ••

Core Software: TriStation 1131 Developer - ••

Programming Languages: IEC 61131-3 (FBD, LD, ST, SFC) - ••

Configuration: Hardware and communication configuration - ••

Online Functions: System monitoring, diagnostics, variable forcing, trip history review - ••

Documentation: Integrated system documentation generator - ••

Simulation: Offline logic simulation and testing - ••

Target Controllers: Tricon CX (v10-v11), Trident - ••

License Type: Node-locked or floating license options - ••

Operating System: Microsoft Windows 7/10/11 (Professional or Enterprise) - ••

Prerequisites: Requires specific .NET Framework and other system components ABB DSTC175