Description

Detailed parameter table

| Parameter name | Parameter value |

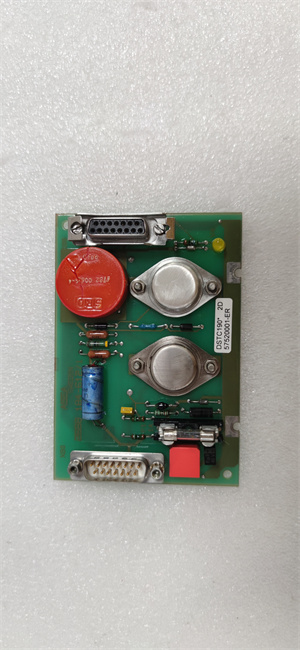

| Product model | DSTC190 |

| Manufacturer | ABB |

| Product category | Digital input module for S800 I/O system |

| Number of channels | 16 digital input channels |

| Input signal type | Dry contacts, 24 V DC (sinking/sourcing) |

| Input voltage range | 15-30 V DC |

| Input current | 3 mA (typical at 24 V DC) |

| Response time | 1 ms (configurable up to 100 ms) |

| Isolation | 2.5 kV AC (channel-to-bus, channel-to-channel) |

| Operating voltage | 24 V DC ±10% |

| Power consumption | ≤ 3 W |

| Operating temperature | -40°C to +70°C |

| Dimensions (W×H×D) | 22 mm × 105 mm × 115 mm |

| Installation method | DIN rail mounting via TB820V2 terminal base |

| Protection class | IP20 |

| Diagnostic features | Channel status LEDs, open circuit detection, overvoltage protection |

| Compliance | IEC 61131-2, EN 61131-2, CE, UL 508 |

| Compatible systems | ABB AC800M controller, S800 I/O rack, CI840A communication module, SPASO11 safety modules |

ABB DSTC190

Product introduction

The DSTC190 is a high-density digital input module from ABB, designed for the S800 I/O system to collect and process discrete signals from industrial sensors and switches. As a critical interface between field devices and the AC800M controller, it converts physical on/off states—from limit switches, proximity sensors, and emergency stops—into digital data for real-time monitoring and control.

With 16 channels in a compact 22 mm width, DSTC190 maximizes space efficiency in control cabinets, making it ideal for applications where panel space is limited. Its flexible support for both sinking and sourcing inputs allows seamless integration with diverse sensor types, eliminating the need for signal converters. Whether deployed in automotive assembly lines monitoring robotic end-effectors or in packaging machines tracking conveyor position, DSTC190 ensures reliable signal acquisition, forming the foundation of responsive automation systems.

Core advantages and technical highlights

High channel density

DSTC190’s 16 channels in a 22 mm housing enable dense mounting—up to 45 modules per meter of DIN rail. In a semiconductor fab’s tool control cabinet, this density allows monitoring of 720 discrete sensors (e.g., door interlocks, vacuum switches) using minimal space, reducing cabinet size by 30% compared to lower-density modules.

Rapid response time

With a configurable 1 ms response time, DSTC190 captures fast-moving events, critical for high-speed processes. In a bottle filling line, it detects a missing bottle via a photoelectric sensor and triggers a reject mechanism via a SPASO11 safety module within 2 ms, preventing unlabeled products from reaching packaging.

Enhanced noise immunity

2.5 kV AC isolation between channels and the system bus protects against electromagnetic interference (EMI) from nearby motors or drives. In a steel mill’s rolling line—where high-voltage equipment generates intense noise—DSTC190 maintains stable readings from temperature switch contacts, avoiding false shutdowns of the mill’s cooling systems.

ABB DSTC190

Typical application scenarios

In an automotive paint shop, DSTC190 serves as the central input hub for process monitoring:

Channels 1-8: Proximity sensors detecting car body position on the conveyor.

Channels 9-12: Limit switches verifying door closure on paint booths.

Channels 13-16: Emergency stop button contacts from workstations.

Data from DSTC190 is sent to the AC800M controller via the S800 I/O bus, which coordinates paint sprayers and conveyor speed. The module’s fast response ensures the system stops within 50 ms if a booth door opens, preventing paint contamination and ensuring operator safety.

In a food processing plant’s packaging area, DSTC190 monitors:

Metal detector status signals (pass/fail).

Film roll end-of-life sensors.

Seal integrity verification switches.

By integrating with a CI840A communication module, the module shares data with a SCADA system, enabling real-time alerts for low film stock or seal failures—reducing waste by 15% and improving packaging quality.

Related model recommendations

DSTC180: 8-channel version of DSTC190 for smaller-scale applications with fewer sensors.

TB820V2: Terminal base required for DSTC190 mounting, featuring secure screw terminals for field wiring.

AC800M PM864: Controller that processes digital input data from DSTC190 to execute control logic.

SPDSO14: Digital output module that pairs with DSTC190 to create complete input-output loops (e.g., sensor-to-actuator control).

CI840A: Profibus module enabling remote monitoring of DSTC190 status in distributed networks.

1SVR011700R0000: 24 V DC power supply providing reliable voltage to DSTC190 and connected sensors.

DSTC290: DSTC190 variant with extended temperature range (-50°C to +85°C) for extreme environments.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing DSTC190, power off the S800 I/O rack and verify isolation with a multimeter. Mount the TB820V2 terminal base on a 35 mm DIN rail, leaving 20 mm clearance between modules for airflow. Use 0.5-1.5 mm² shielded cables to connect field devices to terminals 1-32 (channels 1-16, each with positive and common inputs). Separate sensor wiring from power cables to minimize EMI. Connect 24 V DC power to the terminal base, ensuring correct polarity, and verify compatibility with the AC800M controller before energizing.

Maintenance suggestions

Daily checks of DSTC190 involve confirming green LEDs for power and active channels; red LEDs indicate faults (e.g., open circuits). Test each channel monthly by activating the connected sensor and verifying the module’s digital output in the controller software—this identifies degraded channels early. Inspect terminals quarterly for corrosion, tightening screws to 0.6 Nm if loose. If a channel fails, swap the sensor to a spare channel to isolate issues; replace DSTC190 with an ABB-approved spare if internal faults are confirmed, ensuring the replacement is configured with matching input parameters.

Service and guarantee commitment

The DSTC190 is backed by a 3-year warranty, covering defects in materials and workmanship under normal operating conditions. ABB’s technical support team provides 24/7 assistance for integration with S800 I/O systems, including guidance on wiring, configuration, and troubleshooting with modules like CI840A.

Customers receive access to detailed manuals, including wiring diagrams and diagnostic procedures specific to DSTC190. ABB offers on-site training for maintenance teams, ensuring proper handling and maximum module lifespan. With global distribution centers, replacement DSTC190 modules are available within 48 hours, minimizing downtime in critical automation loops. Trust DSTC190 for reliable digital input processing, backed by ABB’s expertise in industrial control components.