Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | DSTXW110 |

| Manufacturer | ABB |

| Product category | Digital input module (Advant Controller 400 series) |

| Number of channels | 16 digital inputs |

| Input type | 24 V DC (sinking, PNP compatible) |

| Input voltage range | 19.2-30 V DC |

| Input current | 4 mA (typical at 24 V DC) |

| Response time | 0.1 ms (minimum), configurable up to 100 ms |

| Isolation | 2.5 kV AC (channel-to-bus, channel-to-channel) |

| Operating voltage | 24 V DC ±10% |

| Power consumption | ≤ 4 W |

| Operating temperature | -40°C to +70°C |

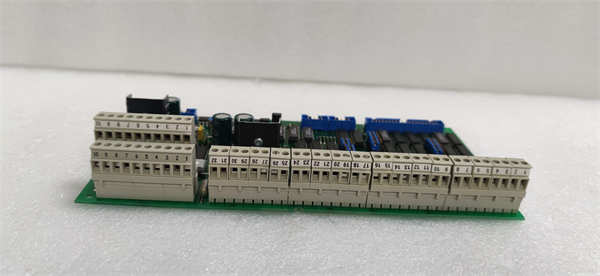

| Dimensions (W×H×D) | 100 mm × 160 mm × 80 mm |

| Installation method | Rack mounting in AC400 controller chassis |

| Diagnostic features | Channel status LEDs, open circuit detection, overvoltage protection |

| Compliance | IEC 61131-2, CE, UL 508, ATEX (Zone 2) |

| Compatible systems | ABB Advant Controller 400, MasterPiece 200/1, XVC768115 3BHB007211R115 termination units, AO910 analog output modules (for closed-loop control) |

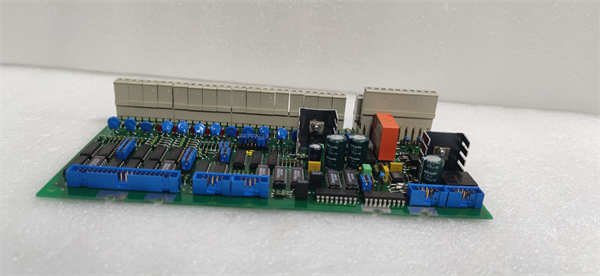

ABB DSTXW110

Product introduction

The DSTXW110 is a high-speed digital input module from ABB, engineered for the Advant Controller 400 series to capture fast-changing discrete signals in industrial automation systems. As a critical interface between high-speed field devices—such as proximity sensors, encoder pulses, and high-frequency limit switches—and the controller, it converts physical events into digital data with microsecond-level precision.

With 16 channels optimized for 24 V DC sinking inputs, DSTXW110 excels in applications requiring rapid signal detection, such as conveyor synchronization, high-speed packaging, and precision machining. Its wide operating temperature range (-40°C to +70°C) ensures reliability in extreme environments, from frozen food processing plants to steel mill control rooms. Whether paired with XVC768115 3BHB007211R115 termination units for organized wiring or integrated with AO910 modules in closed-loop control systems, DSTXW110 delivers consistent performance, enabling real-time decision-making in dynamic industrial processes.

Core advantages and technical highlights

Ultra-fast response time

DSTXW110’s 0.1 ms minimum response time ensures capture of fleeting signals, such as encoder pulses in high-speed rotating machinery. In a bottling line running at 1,000 bottles per minute, this speed allows the module to detect bottle jams within 0.05 ms of occurrence, triggering an immediate stop via a connected AO910 module—preventing equipment damage and product waste.

Robust noise immunity

Designed with enhanced filtering and 2.5 kV AC isolation, DSTXW110 rejects electrical noise from nearby motors and drives. In a metal stamping facility with high-voltage presses, this immunity ensures that electromagnetic interference doesn’t trigger false input signals, maintaining accurate monitoring of die position switches critical for operator safety.

Channel-level diagnostics

Each channel of DSTXW110 features individual status LEDs and open circuit detection, simplifying troubleshooting. In an automotive paint shop, if a conveyor position sensor fails (creating an open circuit), the module’s red LED immediately identifies the faulty channel, allowing technicians to replace the sensor without disrupting the entire line—reducing diagnostic time by up to 70%.

Typical application scenarios

In a high-speed electronics assembly line, DSTXW110 serves as the primary input module for real-time process monitoring:

- Channels 1-8: Monitor 24 V DC proximity sensors tracking printed circuit board (PCB) position on a 5 m/s conveyor, with 0.1 ms response time ensuring no PCBs are missed.

- Channels 9-16: Detect robot gripper position signals, enabling synchronization between pick-and-place robots and the conveyor system.

Paired with an AC400 controller and AO910 modules, DSTXW110 forms a closed-loop system that adjusts conveyor speed based on PCB arrival rates, maximizing throughput while preventing collisions.

In a frozen food packaging plant, DSTXW110 operates reliably in sub-zero temperatures:

- Monitors 24 V DC photoelectric sensors detecting package presence on a refrigerated conveyor (-20°C operating environment).

- Captures limit switch signals from sealing machines, ensuring packages are properly sealed before freezing.

- Works with XVC768115 3BHB007211R115termination units to organize wiring in condensation-prone cabinets, maintaining signal integrity despite moisture.

DSTXW110’s wide temperature tolerance ensures consistent performance in this harsh environment, critical for meeting food safety regulations.

ABB DSTXW110

Related model recommendations

- DSTC190: Digital output module that pairs with DSTXW110for complete I/O functionality in control loops.

- AC400: Advant Controller that processes high-speed inputs from DSTXW110for real-time decision-making.

- XVC768115 3BHB007211R115: Termination unit that organizes field wiring for DSTXW110in high-channel applications.

- AO910: Analog output module that works with DSTXW110to convert input triggers into precise control signals.

- DSTA131: 16-channel digital input module with slower response, complementary to DSTXW110in mixed-speed systems.

- TB521: Terminal block expansion for DSTXW110when additional wiring points are needed.

- CI840A: Profibus module that enables remote monitoring of DSTXW110status in distributed systems.

- SPDSO14: Digital output module that complements DSTXW110in safety-related control loops.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing DSTXW110, power off the AC400 controller chassis and verify isolation with a voltage tester. Insert the module into the designated I/O slot, ensuring secure seating in the backplane, and fasten with front-panel screws (torque to 0.5 Nm). Use 0.5-1.5 mm² shielded twisted-pair cables for field connections, routing them separately from power cables to minimize noise. Connect sensors to terminals 1-32 (16 channels, each with +24 V, signal, and 0 V), verifying polarity for PNP devices. Configure input filtering (0.1-100 ms) via the controller’s software to match sensor signal characteristics.

Maintenance suggestions

Inspect DSTXW110 monthly by checking green power LED and channel activity LEDs—red LEDs indicate faults. Clean module connectors quarterly with compressed air to remove dust and debris. Test input response time annually using a signal generator, ensuring performance remains within 0.1 ms specifications. If a channel fails, swap the sensor to a spare channel to isolate the issue; replace DSTXW110 with an ABB-approved spare if internal faults persist, reconfiguring filtering settings to match the original module.

Service and guarantee commitment

The DSTXW110 is backed by a 2-year warranty, covering defects in materials and workmanship under normal operating conditions. ABB’s legacy systems support team provides technical assistance for integration with Advant Controller 400 series and compatible modules like AO910 and XVC768115 3BHB007211R115.

Customers receive access to archived manuals, wiring diagrams, and configuration guides specific to DSTXW110. ABB offers repair services for faulty modules, extending lifecycle support for legacy installations. With global parts distribution, replacement units are available to minimize downtime in critical high-speed applications. Trust DSTXW110 to deliver reliable high-speed input monitoring, backed by ABB’s commitment to industrial automation excellence.

Full 12-month warranty on all components

Dedicated after-sales support

Same-day dispatch on 1000s of parts

All units are fully tested

- 1. Email confirmation

You will get an email confirming that we have received your enquiry. - 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition. - 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide Full 12-month warranty on all components

Full 12-month warranty on all components