Description

Detailed parameter table

| Parameter name | Parameter value |

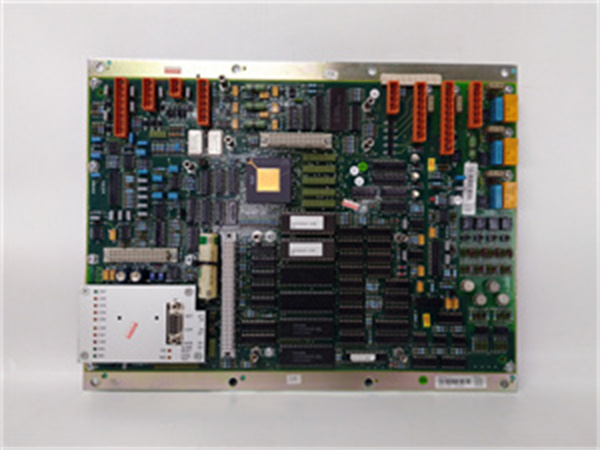

| Product model | DTCC901B |

| Manufacturer | ABB |

| Product category | Digital control and timing module |

| Control channels | 8 (configurable as input/output) |

| Timing resolution | 1 ms |

| Supported protocols | Modbus RTU/TCP, PROFINET IO (via gateway) |

| Communication interfaces | 1 x Ethernet (10/100 Mbps), 1 x RS485 |

| Operating voltage | 24 V DC ±15% |

| Power consumption | Max 4 W |

| Isolation | 2.5 kV AC (channel to backplane) |

| Operating temperature | -40°C to 70°C |

| Protection rating | IP20 |

| Mounting type | Backplane mount (compatible with AC800M/S800 series) |

| Dimensions | 100mm × 160mm × 80mm |

| Certifications | CE, UL, ATEX, IEC 61131-2 |

ABB DTCC901B

Product introduction

The DTCC901B is a versatile digital control and timing module from ABB, engineered to handle precision timing and discrete control tasks in industrial automation systems. As a key component in ABB’s control portfolio, this module bridges high-speed digital signals from field devices (such as limit switches, proximity sensors, and solenoid valves) with central controllers like the 3BHE024577R0101 PPC907BE AMC34 processor, enabling synchronized operations in time-critical applications.

Unlike basic digital I/O modules, the DTCC901B combines configurable channels with millisecond-level timing capabilities, making it ideal for applications requiring precise event sequencing—from packaging line synchronization to conveyor belt coordination. Whether deployed in manufacturing facilities, material handling systems, or process plants, this module ensures accurate control over discrete processes, enhancing operational efficiency and reducing cycle times.

Core advantages and technical highlights

Precision timing control: With a timing resolution of 1 ms, the DTCC901B excels at synchronizing sequential operations. In a high-speed bottling line, it can coordinate bottle filling, capping, and labeling stations with sub-second accuracy, ensuring each step aligns within 2 ms of the target timeline. This precision reduces product waste caused by misalignment and increases throughput by up to 15% compared to standard timing modules.

Configurable I/O channels: The module’s 8 channels can be individually set as inputs or outputs via software, eliminating the need for hardware reconfiguration when system requirements change. In a warehouse sorting system, this flexibility allows operators to repurpose 4 channels from monitoring package sensors (inputs) to activating diverters (outputs) during seasonal demand shifts—all without physical rewiring, saving maintenance time and reducing downtime.

Seamless protocol integration: Equipped with Modbus RTU/TCP and compatibility with PROFINET IO (via gateways like the GCC960C103), the DTCC901B integrates easily with both legacy and modern control systems. In a automotive paint shop, it communicates with a legacy PLC via Modbus RTU to trigger spray gun actuation while sending timing data to a PROFINET-enabled HMI for real-time monitoring—ensuring data consistency across the automation ecosystem.

Robust industrial design: The module operates reliably in extreme temperatures (-40°C to 70°C) and features 2.5 kV AC isolation between channels and backplane, protecting against electrical noise and ground loops. In a steel mill, this ruggedness ensures consistent performance near high-voltage rolling mills, where electromagnetic interference could disrupt standard digital modules. Its ATEX certification also allows deployment in Zone 2 hazardous areas, such as chemical storage facilities.

Advanced diagnostic features: The DTCC901B provides real-time diagnostics, including channel status, signal integrity, and timing drift alerts. In a food processing plant, these diagnostics notify maintenance teams of a failing limit switch on a conveyor (via the HMI80 panel) before it causes a jam, reducing unplanned downtime by enabling proactive part replacement. Diagnostic data is logged to the controller, supporting root-cause analysis for recurring issues.

Typical application scenarios

In a pharmaceutical packaging line, the DTCC901B manages the synchronization of blister packaging machines and cartoners. It uses 4 input channels to monitor blister seal integrity (via pressure sensors) and 4 output channels to trigger carton folding mechanisms, ensuring each blister pack aligns with its carton within 5 ms. The module’s timing data is transmitted to the PPC907BE AMC34 processor, which adjusts speeds dynamically to maintain throughput while adhering to strict FDA-mandated packaging standards.

In a municipal wastewater treatment plant, the module controls the sequencing of valve actuators in a filtration system. It monitors filter pressure (via AI880-1 analog inputs converted to digital triggers) and activates backwash valves at precise 12-hour intervals, with 1 ms timing accuracy to prevent overpressure. Its Modbus TCP interface connects to a SCADA system, allowing operators to adjust cycle times remotely during peak flow periods, optimizing water treatment efficiency.

ABB DTCC901B

Related model recommendations

DTCC902B: A 16-channel variant of the DTCC901B for larger systems requiring more I/O points.

GCC960C103: ABB’s communication gateway that enables PROFINET IO integration for the DTCC901B.

3BHE024577R0101 PPC907BE AMC34: ABB’s processor module that coordinates with the DTCC901B for centralized control.

PPD513A25-111615 3BHE039724R2565: ABB’s power distribution module that supplies stable power to the digital control module.

AI880-1: ABB’s analog input module that provides process data to the DTCC901B for trigger signals.

B5EEd HENF105082R4: ABB’s fieldbus module that integrates with the DTCC901B in mixed-protocol environments.

HMI80: ABB’s touchscreen panel that visualizes timing data and diagnostics from the DTCC901B.

Installation, commissioning and maintenance instructions

Installation preparation: Mount the DTCC901B into a compatible S800 backplane using the front-panel screw, torquing to 0.5 Nm. Ensure at least 50mm clearance for ventilation. Connect field devices using 0.5-1 mm² shielded twisted-pair cable, with inputs wired to sensors and outputs to actuators. Ground all shields at the module end. For communication, attach Ethernet (Cat 5e) and RS485 (shielded) cables. Required tools include a torque screwdriver, wire strippers, and a multimeter. Power off the backplane during installation.

Commissioning steps: Use ABB’s Control Builder M software to configure channel types (input/output), timing parameters (delay, pulse width), and communication settings (IP address, Modbus registers). Map digital signals to the controller’s address space and test trigger sequences by simulating sensor inputs (e.g., manually activating a limit switch). Verify timing accuracy with a oscilloscope, ensuring pulses align within 1 ms of setpoints. Save configurations to non-volatile memory and validate data transmission to the central control system.

Maintenance suggestions: Inspect the module quarterly for loose connections, dust accumulation, and LED status (power: green, communication: flashing green, channel faults: red). Clean ventilation slots with compressed air. Test isolation resistance annually using a megohmmeter (minimum 100 MΩ at 500 V DC). Calibrate timing references semi-annually against a GPS clock to maintain 1 ms accuracy. If channels fail to respond, check field wiring and replace faulty sensors before replacing the module with an ABB-certified unit.

Service and guarantee commitment

The DTCC901B comes with a 5-year warranty from installation, covering manufacturing defects and ensuring compliance with published performance specifications. ABB guarantees technical support response within 4 hours for critical applications, with on-site troubleshooting available in 72 hours for qualified industrial facilities. The module includes 3 years of free firmware updates and access to configuration tools. Extended service contracts offer annual calibration, preventive maintenance, and priority support, ensuring reliable operation throughout its 15-year design lifespan. Customers receive dedicated online resources, including wiring diagrams, timing configuration guides, and troubleshooting manuals specific to this model.