Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | DTCC901B 61430001-FU |

| Manufacturer | ABB |

| Product category | Terminal connection module |

| Rated voltage | 600 V AC/DC (max) |

| Rated current | 20 A per terminal |

| Number of terminals | 36 (18 input, 18 output) |

| Terminal type | Push-in spring clamp (tool-free) |

| Wire size range | 0.5 – 2.5 mm² (solid/stranded, with ferrule) |

| Insulation material | Polyamide (PA66), flame-retardant (UL94 V-0) |

| Operating temperature | -40°C to 80°C |

| Dimensions | 150 mm × 60 mm × 30 mm |

| Mounting type | DIN rail mount (35 mm) |

| Protection rating | IP20 |

| Certifications | IEC 60947-7-1, CE, UL, RoHS |

| Color coding | Inputs (green), outputs (gray) for easy identification |

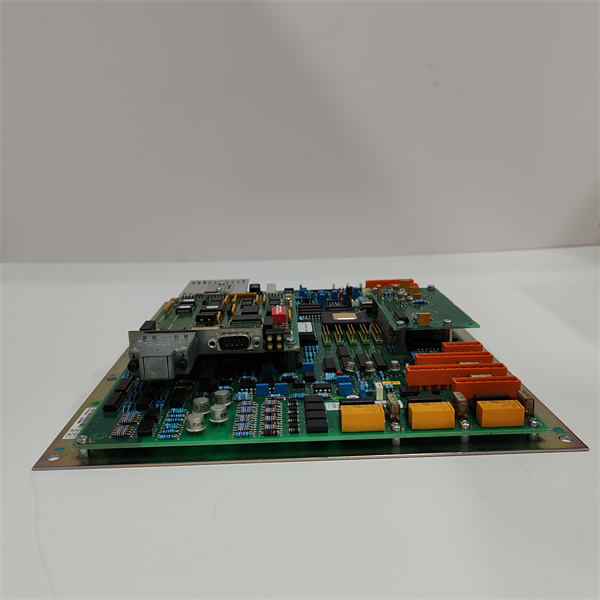

ABB DTCC901B 61430001-FU

Product introduction

The DTCC901B 61430001-FU is a high-density terminal connection module from ABB, engineered for light to medium-duty industrial control systems where space efficiency and rapid wiring are priorities. Positioned as a compact alternative to the DYPS154C, this module specializes in handling a large number of small-gauge wires—making it ideal for signal-intensive applications such as sensor networks, instrumentation panels, and low-power automation systems.

Unlike the DYPS154C’s hybrid clamp design, the DTCC901B features pure push-in spring clamps that eliminate the need for any tools during installation. This tool-free approach, combined with its 36 terminals (the highest density in its class), makes it a go-to choice for systems with extensive signal wiring, such as factory automation lines with numerous proximity sensors or building management systems with multiple environmental detectors.

Core advantages and technical highlights

Ultra-high density wiring

With 36 terminals packed into a 150 mm × 60 mm footprint, the DTCC901B offers 50% more connection points than the DYPS154C (24 terminals) in a similar width. This density is critical for crowded control panels, such as those in semiconductor cleanrooms, where 18 temperature sensors and 18 pressure transducers need to be wired to a central controller without expanding cabinet size. The compact design reduces cable routing complexity, minimizing the risk of wire tangling or signal interference.

Tool-free push-in terminals

The module’s push-in spring clamps accept 0.5 – 2.5 mm² wires (with ferrules) via a simple insertion motion—no levers, screws, or tools required. This cuts installation time by up to 60% compared to the DYPS154C, a significant advantage in large-scale projects like automotive assembly lines with hundreds of sensors. For example, a technician can wire 36 proximity sensors in under 10 minutes, versus 25 minutes with a hybrid clamp module.

Secure signal integrity

Designed specifically for low-power signal wires, the DTCC901B’s spring clamps maintain consistent pressure (12 – 18 N) to prevent micro-arcing and signal loss—critical for analog sensors (e.g., 4-20 mA pressure transducers). In a pharmaceutical manufacturing line, this ensures precise transmission of pH and conductivity readings from 18 fermenters to a control system, avoiding costly batch errors due to signal degradation.

Extreme cold tolerance

Rated to -40°C, the module matches the DYPS154C’s cold-weather performance, making it suitable for outdoor sensors in refrigerated warehouses or Arctic research stations. Its PA66 housing remains flexible at low temperatures, preventing terminal cracking during thermal cycling—unlike brittle plastics used in cheaper alternatives.

Key differences from DYPS154C 61430001-YP

| Feature | DYPS154C | DTCC901B |

| Rated current | 32 A per terminal | 20 A per terminal |

| Max voltage | 800 V AC/DC | 600 V AC/DC |

| Terminal type | Screw-assisted spring clamp | Push-in spring clamp (tool-free) |

| Wire size range | 0.75 – 4 mm² | 0.5 – 2.5 mm² (with ferrule) |

| Number of terminals | 24 (12 input, 12 output) | 36 (18 input, 18 output) |

| Operating temperature range | -40°C to 85°C | -40°C to 80°C |

| Insulation material | PA66 + glass fiber | PA66 |

| Color coding | Inputs (yellow), outputs (white) | Inputs (green), outputs (gray) |

ABB DTCC901B 61430001-FU

Typical application scenarios

Sensor networks in factory automation

In a electronics manufacturing plant, the DTCC901B connects 18 optical sensors (detecting circuit board presence) and 18 robotic arm position sensors (0.5 mm² wires) to a PLC. Its push-in terminals allow quick reconfiguration when production lines switch between product models, while the 36 terminals eliminate the need for two separate modules—saving 30% of panel space.

Building automation sensors

A smart office building uses the module to wire 18 CO₂ detectors and 18 occupancy sensors (1 mm² wires) to a BMS controller. The tool-free design simplifies installation by electricians without specialized training, and green/gray color coding ensures correct polarity when connecting DC-powered sensors.

Laboratory instrumentation

In a chemical lab, the DTCC901B links 18 analytical instruments (e.g., spectrometers) and 18 sample valve actuators (2.5 mm² wires) to a data acquisition system. Its secure signal transmission prevents noise interference in sensitive measurements, while the compact size fits into benchtop control enclosures.

Related model recommendations

ABB DYPS154C 61430001-YP

Complements the DTCC901B in mixed systems, handling 4 mm² power wires for actuators while the DTCC901B manages signal wiring—creating a complete low/high-power connection solution.

ABB TB857 surge protector

Installed upstream to shield the DTCC901B from voltage spikes in sensor networks, preventing damage to delicate spring clamps.

ABB MNS3.0 mini enclosure

A compact cabinet designed to house the DTCC901B and small PLCs, ideal for distributed sensor nodes in large facilities.

ABB ZB5-G terminal markers

Green-labeled markers that align with the DTCC901B’s color coding, simplifying wire tracing in complex sensor arrays.

ABB Ferrule set 0.5 – 2.5 mm²

Required for optimal performance with the push-in terminals, ensuring secure wire retention and preventing strand fraying.

Installation, commissioning and maintenance instructions

Installation: Mount on a 35 mm DIN rail with 5 mm clearance for ventilation. Prepare wires with ferrules (0.5 – 2.5 mm²), strip to 8 mm, and push firmly into terminals until a click is heard (no tools needed). Connect green terminals to field sensors, gray terminals to control systems. Avoid exceeding 20 A per terminal or 600 V.

Commissioning: Verify wire retention by gently tugging each conductor. Test continuity between input/output pairs with a multimeter to confirm correct wiring. For analog signals, use an oscilloscope to check for noise—ensure no loose connections are causing signal degradation.

Maintenance: Inspect quarterly for dust (clean with compressed air). Check for wire backout in high-vibration areas (e.g., near motors) and reinsert if needed. Replace the module if terminals show corrosion or spring tension weakens (indicated by easy wire removal).

Service and guarantee commitment

The DTCC901B 61430001-FU is backed by a 10-year warranty, covering manufacturing defects and compliance with IEC 60947-7-1. ABB’s technical support provides guidance on ferrule selection and high-density wiring best practices.

Extended service includes access to 3D CAD models for panel design and bulk packaging for large sensor network projects. ABB guarantees RoHS compliance, ensuring compatibility with global environmental standards. This commitment solidifies the DTCC901B’s role as a reliable, efficient solution for signal-intensive industrial wiring.