Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | DYPS154C 61430001-YP |

| Manufacturer | ABB |

| Product category | Terminal connection module |

| Rated voltage | 800 V AC/DC (max) |

| Rated current | 32 A per terminal |

| Number of terminals | 24 (12 input, 12 output) |

| Terminal type | Hybrid clamp (screw-assisted spring clamp) |

| Wire size range | 0.75 – 4 mm² (solid/stranded) |

| Insulation material | Polyamide (PA66 + glass fiber), flame-retardant (UL94 V-0) |

| Operating temperature | -40°C to 85°C |

| Dimensions | 110 mm × 65 mm × 32 mm |

| Mounting type | DIN rail mount (35 mm) |

| Protection rating | IP20 |

| Certifications | IEC 60947-7-1, CE, UL, RoHS |

| Color coding | Inputs (yellow), outputs (white) for easy identification |

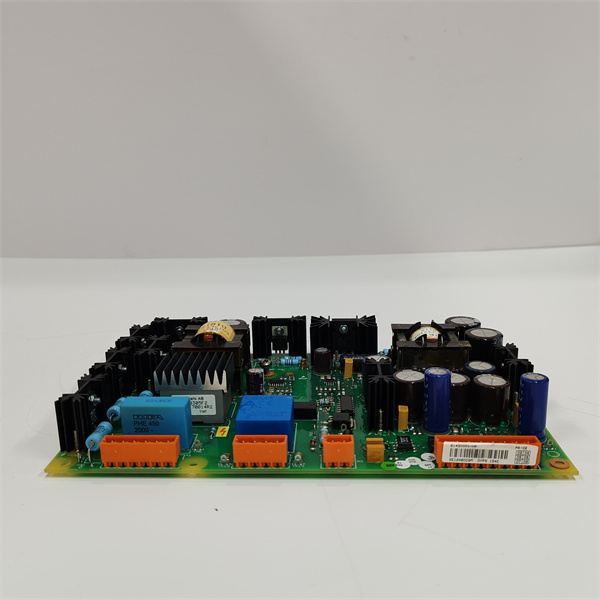

ABB DYPS154C 61430001-YP

Product introduction

The DYPS154C 61430001-YP is a versatile terminal connection module from ABB, designed to balance flexibility and reliability in mid-range industrial control systems. Positioned between the DYTP123A (light-duty) and DYSF118B (heavy-duty), this module combines the speed of spring clamps with the precision of screw adjustment, making it ideal for applications where both quick installation and secure connections are required—such as automated production lines, medium-power motor control panels, and building management systems.

Unlike the DYSF118B’s torque-controlled screw terminals, the DYPS154C features a hybrid clamp design: a spring provides consistent clamping force, while a screw allows fine adjustment for different wire gauges. This hybrid approach eliminates the need for specialized torque tools during installation (saving time) while ensuring vibration resistance (critical for machinery). Its 32 A current rating and 24 terminals strike a balance between density and power handling, catering to systems with moderate wiring complexity.

Core advantages and technical highlights

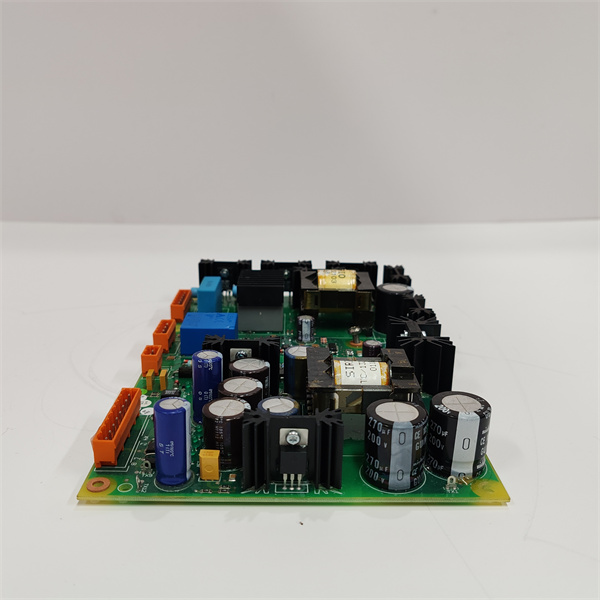

Hybrid clamp technology

The module’s screw-assisted spring clamps merge the best of both worlds: spring-loaded contacts ensure constant pressure (preventing loosening from vibration) and a screw allows manual adjustment to accommodate wire sizes from 0.75 to 4 mm². This design reduces installation time by 30% compared to the DYSF118B’s pure screw terminals while maintaining equivalent connection reliability. In a packaging machine with frequent sensor upgrades, technicians can quickly swap 2 mm² signal wires without tools, then use a screwdriver to secure 4 mm² power leads—all in the same module.

Mid-range power with high density

With 24 terminals in a compact 110 mm × 65 mm footprint, the DYPS154C offers higher density than the DYSF118B (18 terminals) while handling 32 A—sufficient for medium motors, pumps, and heating elements. In a commercial HVAC control panel, this density allows wiring 12 temperature sensors (0.75 mm²) and 12 damper actuators (4 mm²) in a single module, reducing cabinet size by 20% compared to using separate light and heavy-duty terminals.

Extreme temperature resilience

Rated to -40°C, the module outperforms the DYSF118B (-30°C) in cold environments—critical for outdoor enclosures, refrigeration systems, or polar region installations. Its glass-fiber-reinforced polyamide housing resists thermal expansion/contraction, ensuring terminal integrity even during rapid temperature swings (e.g., warehouse freezers cycling between -20°C and 25°C during defrost).

Tool versatility

While the spring clamp allows tool-free wire insertion for 0.75 – 2.5 mm² wires, the screw can be tightened with a standard flathead screwdriver for 4 mm² cables or in high-vibration areas. This flexibility eliminates the need for torque wrenches (required for the DYSF118B) while providing a backup method to secure critical connections. In a mobile machinery control box (e.g., agricultural equipment), this ensures reliable wiring despite constant movement.

Key differences from DYSF118B 61430001-XG

| Feature | DYSF118B | DYPS154C |

| Rated current | 40 A per terminal | 32 A per terminal |

| Max voltage | 1000 V AC/DC | 800 V AC/DC |

| Terminal type | Torque-controlled screw clamp | Screw-assisted spring clamp |

| Wire size range | 1.5 – 6 mm² | 0.75 – 4 mm² |

| Number of terminals | 18 (9 input, 9 output) | 24 (12 input, 12 output) |

| Operating temperature range | -30°C to 90°C | -40°C to 85°C |

| Insulation material | Polyester (PET) | Polyamide (PA66 + glass fiber) |

| Color coding | Inputs (red), outputs (black) | Inputs (yellow), outputs (white) |

ABB DYPS154C 61430001-YP

Typical application scenarios

Automated production lines

In a car battery assembly line, the DYPS154C connects 12 proximity sensors (0.75 mm²) and 12 conveyor motor starters (4 mm²) to a PLC. Its hybrid clamps allow quick sensor swaps during line reconfigurations, while the screw adjustment secures motor leads against conveyor vibrations. The 24 terminals consolidate wiring, reducing panel clutter compared to using separate DYTP123A and DYSF118B modules.

Building management systems

In a shopping mall’s BMS panel, the module links 12 HVAC zone sensors (1 mm²) and 12 fan coil actuators (2.5 mm²) to a controller. The 800 V rating handles the mall’s 400 V three-phase power, while the -40°C tolerance ensures reliability in rooftop enclosures during winter. Yellow/white color coding simplifies troubleshooting when adjusting airflow in specific zones.

Renewable microgrids

In a small-scale solar + storage system, the DYPS154C connects 12 battery monitoring sensors (0.75 mm²) and 12 inverter outputs (4 mm²) to a control system. Its hybrid clamps accommodate both fine signal wires and thicker power cables, while the vibration resistance (from spring clamps) ensures connections remain secure on rooftop installations exposed to wind.

Related model recommendations

ABB PCD235C101 3BHE057901R0101

The DYPS154C serves as the mid-power connection hub for the PCD235C101, linking the control module to sensors and actuators in medium-complexity systems. Together, they balance control precision and wiring efficiency.

ABB DYSF118B 61430001-XG

For high-power branches within the same system (e.g., a 40 A pump alongside 32 A fans), the DYSF118B complements the DYPS154C, handling larger wires while maintaining consistent color-coded logic.

ABB TB857 surge protector

Installed upstream, it shields the DYPS154C from voltage spikes in industrial grids, preserving connection integrity in regions with unstable power.

ABB MNS3.0 compact enclosure

A space-efficient cabinet designed to house the DYPS154C and associated control gear, with pre-routed DIN rails for easy module alignment.

ABB ZB5-Y terminal markers

Yellow-labeled markers that align with the DYPS154C’s color coding, enhancing traceability in systems with multiple terminal modules.

Installation, commissioning and maintenance instructions

Installation: Mount on a 35 mm DIN rail with 10 mm clearance for ventilation. For 0.75 – 2.5 mm² wires: strip to 8 mm, press the orange lever to open the clamp, insert wire, and release (tool-free). For 4 mm² wires: use a screwdriver to back off the adjustment screw, insert stripped wire (10 mm), then tighten the screw until snug (no torque tool needed). Connect yellow terminals to field devices, white terminals to control modules.

Commissioning: Verify all wires are fully seated by gently tugging. For critical connections (e.g., motor leads), use a screwdriver to ensure the adjustment screw is tight. Test continuity between input/output pairs with a multimeter to confirm no cross-wiring.

Maintenance: Inspect quarterly for dust (clean with compressed air) and loose wires. In high-vibration areas, check 4 mm² connections semi-annually—retighten adjustment screws if needed. Replace the module if clamps show corrosion or the housing cracks (common in chemical-exposed environments).

Service and guarantee commitment

The DYPS154C 61430001-YP comes with a 10-year warranty, covering manufacturing defects and compliance with IEC 60947-7-1. ABB’s technical support provides guidance on hybrid clamp installation and wire gauge compatibility, ensuring optimal performance.

Extended service includes access to wiring diagrams, 3D models for enclosure design, and bulk packaging for large projects. ABB guarantees RoHS compliance, making it suitable for global applications. This commitment positions the DYPS154C as a reliable, flexible solution for mid-range industrial wiring.