Description

Detailed parameter table

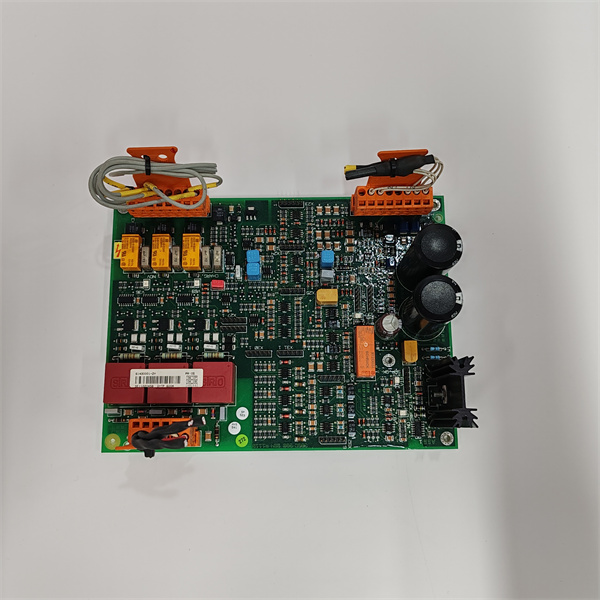

| Parameter name | Parameter value |

| Product model | DYTP600A 61430001-ZY |

| Manufacturer | ABB |

| Product category | Terminal connection module |

| Rated voltage | 1000 V AC/DC (max) |

| Rated current | 63 A per terminal |

| Number of terminals | 12 (6 input, 6 output) |

| Terminal type | Heavy-duty screw clamp (with captive screw) |

| Wire size range | 4 – 10 mm² (solid/stranded, with or without ferrule) |

| Insulation material | Polyamide (PA66 + 30% glass fiber), flame-retardant (UL94 V-0) |

| Operating temperature | -30°C to 90°C |

| Dimensions | 140 mm × 80 mm × 40 mm |

| Mounting type | DIN rail mount (35 mm) with locking clip |

| Protection rating | IP20 |

| Certifications | IEC 60947-7-1, CE, UL, RoHS, ATEX Zone 2 |

| Color coding | Inputs (black), outputs (red) for easy identification |

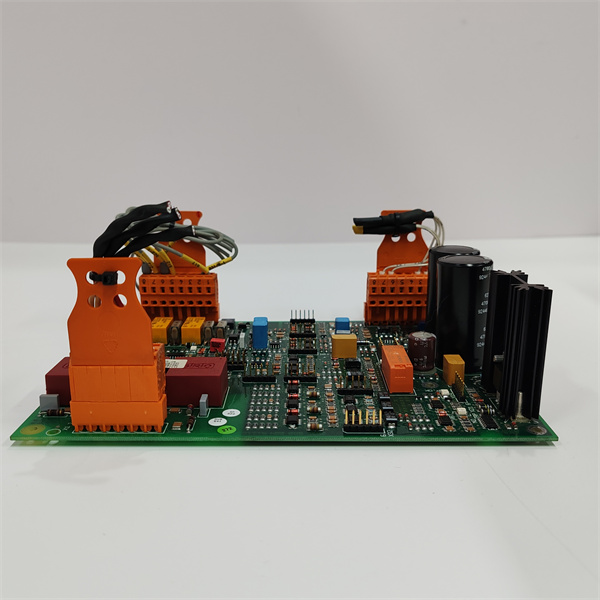

ABB DYTP600A 61430001-ZY

Product introduction

The DYTP600A 61430001-ZY is a heavy-duty terminal connection module from ABB, designed to handle high-current and high-voltage applications in industrial power distribution systems. Positioned as a high-power alternative to the DTCC901B, this module is engineered for scenarios where robust connections for large-gauge wires are essential—such as main distribution panels, motor control centers for heavy machinery, and high-power renewable energy systems.

Unlike the DTCC901B’s focus on high-density signal wiring, the DYTP600A prioritizes power handling capability with its 63 A current rating and 1000 V voltage tolerance. Its heavy-duty screw clamps with captive screws ensure secure connections even under extreme mechanical stress, making it ideal for applications with high vibration or thermal cycling, such as steel mills, mining operations, and large-scale manufacturing plants.

Core advantages and technical highlights

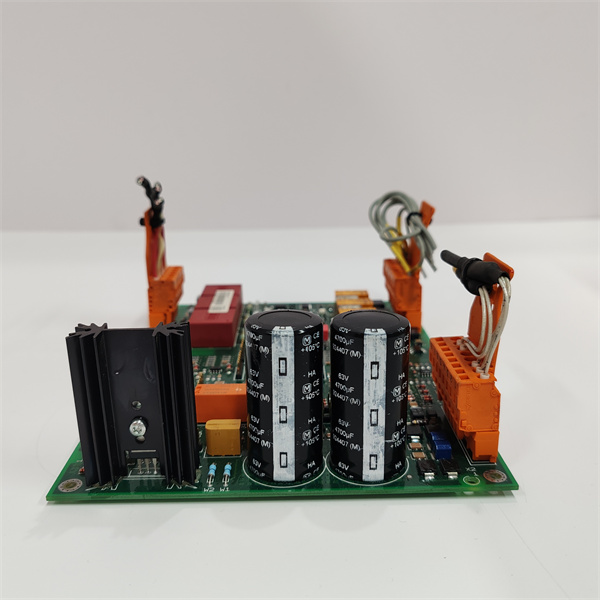

High-power handling capacity

With a rated current of 63 A per terminal (more than three times that of the DTCC901B’s 20 A) and a maximum voltage of 1000 V AC/DC, the DYTP600A is built to manage heavy electrical loads. This makes it suitable for connecting large motors, transformers, and power distribution components. In a steel mill’s hot rolling facility, for example, it can reliably handle the 50 A current from a 100 HP motor drive, ensuring stable power transmission without overheating.

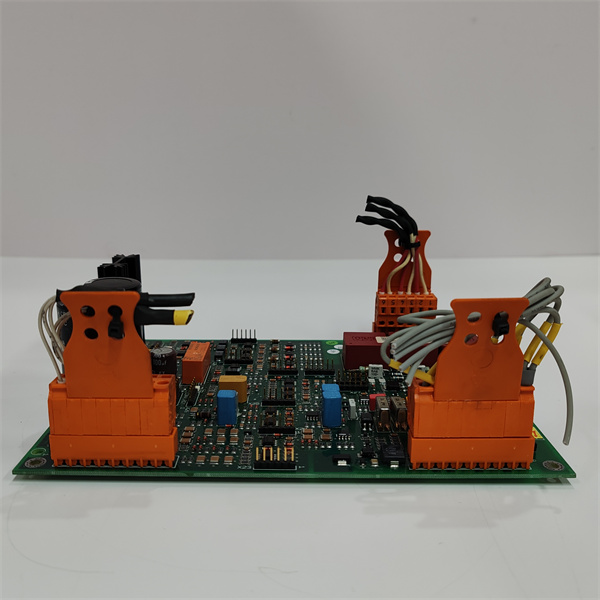

Heavy-duty screw clamps with captive screws

The module features robust screw clamps with captive screws (preventing loss during maintenance) that provide a secure, torque-controlled connection (2.5 – 3.0 Nm). This design ensures consistent clamping force even in high-vibration environments, such as near industrial compressors or rock crushers. Unlike the DTCC901B’s push-in terminals, which are designed for small wires, these clamps accommodate 4 – 10 mm² cables, eliminating the need for additional adapters.

Enhanced mechanical strength

Constructed from polyamide with 30% glass fiber reinforcement, the DYTP600A’s housing offers superior mechanical strength and thermal resistance compared to the DTCC901B’s standard PA66. It can withstand accidental impacts during panel installation and resists warping at high temperatures (up to 90°C), ensuring terminal alignment remains precise over time. In a foundry where ambient temperatures often reach 80°C, this durability prevents terminal degradation and maintains connection integrity.

ATEX Zone 2 certification

Unlike the DTCC901B, the DYTP600A is certified for use in ATEX Zone 2 hazardous areas, making it suitable for applications in chemical plants, oil refineries, and gas processing facilities. Its design minimizes spark risk, with smooth surfaces and non-ferrous components that prevent static buildup—critical for safe operation near flammable substances.

Key differences from DTCC901B 61430001-FU

| Feature | DTCC901B | DYTP600A |

| Rated current | 20 A per terminal | 63 A per terminal |

| Max voltage | 600 V AC/DC | 1000 V AC/DC |

| Terminal type | Push-in spring clamp (tool-free) | Heavy-duty screw clamp (captive screw) |

| Wire size range | 0.5 – 2.5 mm² (with ferrule) | 4 – 10 mm² (with or without ferrule) |

| Number of terminals | 36 (18 input, 18 output) | 12 (6 input, 6 output) |

| Operating temperature range | -40°C to 80°C | -30°C to 90°C |

| Insulation material | PA66 | PA66 + 30% glass fiber |

| Certifications | IEC 60947-7-1, CE, UL, RoHS | IEC 60947-7-1, CE, UL, RoHS, ATEX Zone 2 |

| Color coding | Inputs (green), outputs (gray) | Inputs (black), outputs (red) |

ABB DYTP600A 61430001-ZY

Typical application scenarios

Motor control centers for heavy machinery

In a mining operation, the DYTP600A connects 6 large conveyor motors (10 mm² wires) to their respective variable frequency drives. Its heavy-duty screw clamps, tightened to 3.0 Nm, ensure secure connections despite the constant vibration from the machinery. The ATEX certification allows installation in areas where methane gas may be present, ensuring safe operation.

Power distribution panels in industrial plants

In a chemical processing plant, the module links 6 main circuit breakers to busbars and branch circuits (6 mm² wires). Its 1000 V rating handles the plant’s 690 V three-phase power, while the robust housing resists corrosion from chemical fumes. The red/black color coding helps electricians quickly identify power inputs and outputs during maintenance.

Renewable energy systems

In a large-scale solar farm, the DYTP600A connects 6 string inverters (8 mm² wires) to the main combiner box. Its high-temperature tolerance (up to 90°C) ensures reliable operation in the inverter cabinet, where temperatures can rise significantly during peak sunlight hours. The secure screw clamps prevent connection loosening due to thermal expansion and contraction.

Related model recommendations

ABB DTCC901B 61430001-FU

Complements the DYTP600A in mixed systems, handling signal wiring for sensors and controls while the DYTP600A manages high-power connections—providing a complete solution for both power and signal needs.

ABB TB857 surge protector

Installed upstream of the DYTP600A to protect against voltage transients in high-power circuits, safeguarding the module and connected equipment from damage.

ABB MNS-XL enclosure

A heavy-duty control cabinet designed to house the DYTP600A and other high-power components, with reinforced walls and cooling systems to handle the heat generated by large currents.

ABB SKM200GB12V4 IGBT module

When paired with the DYTP600A, this power semiconductor module enables precise control of high-current motors, with the DYTP600A managing the power connections.

ABB ZB5-R terminal marker set

Red-labeled markers that align with the DYTP600A’s color coding, enhancing traceability in complex power distribution systems.

Installation, commissioning and maintenance instructions

Installation: Mount the DYTP600A on a 35 mm DIN rail using the locking clip to prevent movement. Connect input terminals (black) to power sources or field devices, and output terminals (red) to load devices. Strip wires to 12 – 15 mm, insert into terminals, and tighten screws to 2.5 – 3.0 Nm using a torque wrench. Use 4 – 10 mm² stranded or solid wire, ensuring no stray strands are exposed. In ATEX Zone 2 areas, follow proper hazardous area installation procedures, including using flame-retardant conduit.

Commissioning: After installation, verify torque settings on all terminals using a calibrated torque wrench. Check continuity between connected devices using a multimeter to ensure proper wiring. Perform a high-voltage insulation test (up to 1000 V) to confirm insulation integrity between terminals and ground. In hazardous areas, ensure all connections comply with ATEX regulations.

Maintenance: Inspect the module semi-annually for signs of overheating (discoloration), corrosion, or loose connections. Re-tighten terminals to the specified torque if necessary. Clean dust and debris using a soft brush or compressed air. Replace the module if terminals show signs of excessive wear, cracking, or if the housing is damaged. In high-vibration environments, check torque quarterly to prevent loosening.

Service and guarantee commitment

The DYTP600A 61430001-ZY is backed by a 10-year warranty, covering manufacturing defects and ensuring compliance with IEC 60947-7-1 and ATEX standards. ABB’s technical support provides guidance on proper installation, including torque specifications and hazardous area requirements, to ensure optimal performance.

Extended service includes access to detailed installation guides, 3D CAD models for enclosure design, and bulk packaging options for large-scale projects. ABB guarantees that the module meets RoHS and REACH environmental standards, making it suitable for use in global industrial applications. This commitment underscores the DYTP600A’s role as a reliable, long-lasting solution for high-power terminal connections.