Description

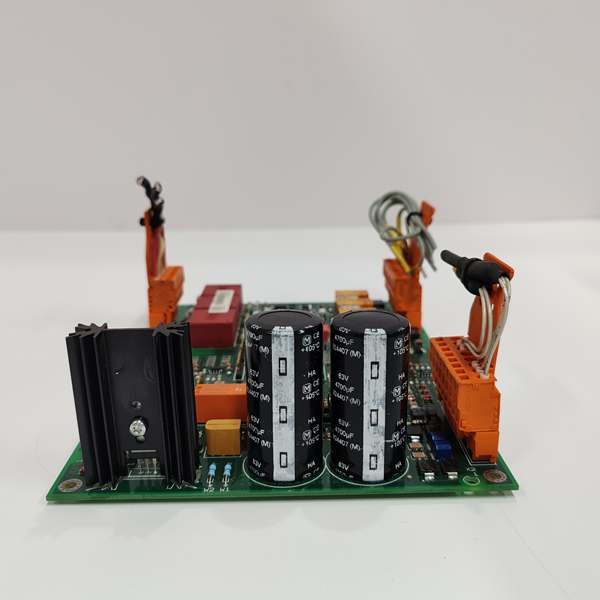

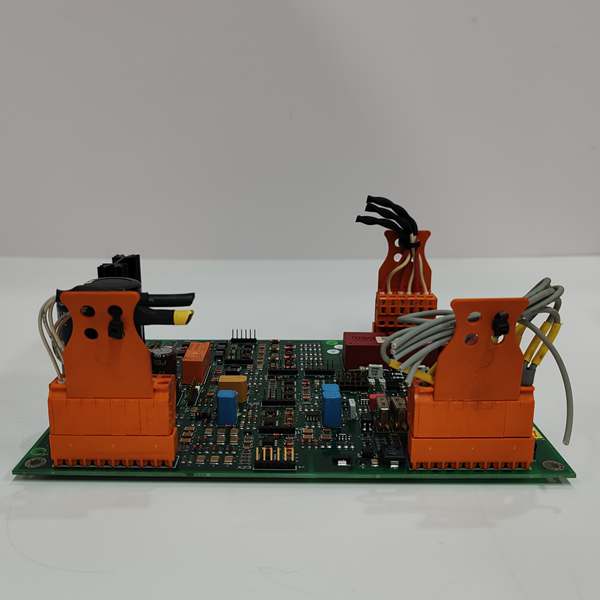

DYTP600A 61430001-ZY: Product Overview

This module occupies the power conversion layer within ABB ACS series variable frequency drive (VFD) systems, positioned between the AC input rectifier and motor inverter stage. Its role is to regulate DC link voltage (typically 540–720V DC) for downstream IGBT inverters, ensuring stable power delivery to AC motors (induction or synchronous) in high-torque applications. In a typical drive architecture, it receives filtered AC input, performs power factor correction, and outputs a stabilized DC voltage to the inverter section, which then generates variable-frequency AC for motor speed control.

Core functionality includes handling 600A continuous DC output current (800A peak for 10s), suppressing input harmonic distortion (<5% THD), and integrating protective circuits (overcurrent, overvoltage, overtemperature) to safeguard the drive system. It utilizes thyristor-based phase-controlled rectification for robust performance in harsh environments, with forced-air cooling to manage thermal loads during sustained operation.

The module belongs to the ABB ACS Series Industrial Drive Systems platform, designed for heavy-duty motor control in sectors like steel, mining, and ports. Benefits of this platform include modular power stages (allowing scalable drive ratings), compatibility with ABB DriveWindow configuration software, and compliance with IEC 61800-5-1 safety standards. This series simplifies system integration by standardizing power module interfaces, reducing engineering time for custom drive assemblies.

ABB DYTP600A 61430001-ZY

DYTP600A 61430001-ZY: Technical Specifications

-

Model Number: DYTP600A 61430001-ZY

-

Manufacturer: ABB Ltd.

-

Product Type: AC Drive Power Module

-

Input Voltage: 480V AC (3-phase, ±10%, 50/60Hz)

-

Output Current: 600A DC continuous / 800A DC peak (10s)

-

DC Link Voltage: 540–720V DC (regulated)

-

Efficiency: 98% (typical at full load)

-

Switching Frequency: 6 kHz (thyristor phase control)

-

Protection Features: Overcurrent (OC), Overvoltage (OV), Overtemperature (OT), Short-Circuit (SC)

-

Cooling Method: Forced-air (integrated fans, 24V DC supply)

-

Operating Temperature: 0°C to +50°C (module); -20°C to +60°C (controller)

-

Storage Temperature: -40°C to +85°C

-

Dimensions: 400mm (H) x 300mm (W) x 200mm (D)

-

Weight: ~25kg

-

Certifications: CE, UL (cULus Listed), RoHS, IEC 61800-5-1

Core Features & Customer Value

The 600A DC output capacity supports large induction motors (up to 500kW) in applications like steel mill roller drives, where high torque at low speeds is required. For engineers, this eliminates the need for multiple parallel power modules, simplifying drive cabinet design. The 98% efficiency reduces energy losses during continuous operation, lowering operational costs in 24/7 facilities such as cement plants or mining conveyors.

Integrated thyristor phase control minimizes input current harmonics (<5% THD), ensuring compliance with IEEE 519 standards for industrial power quality. This prevents penalties from utility companies and reduces heating in upstream transformers. The forced-air cooling system, with redundant fans, maintains thermal stability during peak loads—critical for applications like crusher drives that experience frequent load spikes.

Protective circuits (OC/OV/OT) trigger soft shutdowns to prevent module damage, reducing unplanned downtime. For maintenance teams, the module’s plug-in design (mounted on a guide rail) enables quick replacement, with alignment pins ensuring correct positioning. Compatibility with ABB DriveWindow software allows remote monitoring of DC link voltage and temperature, facilitating predictive maintenance.

ABB DYTP600A 61430001-ZY

Typical Applications

In steel production, the module powers the main drive of a hot strip mill finishing stand, delivering 600A DC to the inverter for precise roller speed control (±0.1% accuracy). The robust construction withstands vibration from adjacent mill stands.

For mining operations, it drives the primary crusher motor (400kW induction motor) in an open-pit mine, handling intermittent overloads during ore surges. The IP54-rated enclosure (when installed in a sealed cabinet) resists dust and moisture.

In port logistics, the module controls the hoist motor of a container crane, providing smooth torque during heavy load lifting (50-ton containers). The 800A peak current supports rapid acceleration without voltage sag.