Description

Detailed parameter table

| Parameter name | Parameter value |

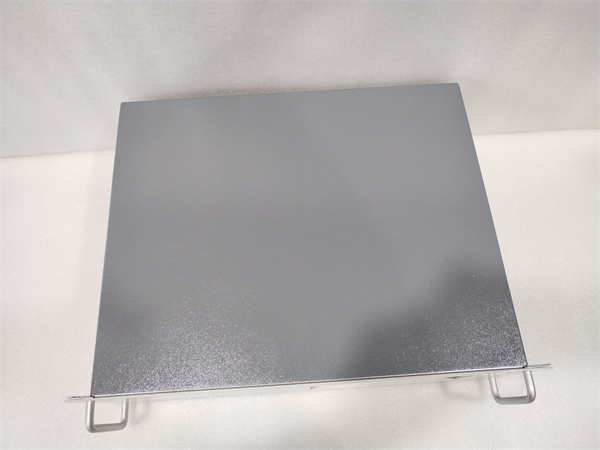

| Product model | EL3020 |

| Manufacturer | ABB |

| Product category | Safety I/O Module for Industrial Safety Systems |

| Operating voltage | 24 VDC ±10% |

| Power consumption | 5 W typical, 7 W maximum |

| Safety integrity level | SIL 3 (per IEC 61508); PL e (per ISO 13849-1) |

| Input channels | 8 safety inputs (configurable as NPN or PNP) |

| Output channels | 4 safety outputs (2 x 2-channel redundant) |

| Communication interface | Safety over Ethernet (PROFIsafe) |

| Response time | <5 ms for input processing; <8 ms for output activation |

| Operating temperature | -25°C to +65°C (-13°F to +149°F) |

| Humidity tolerance | 5% to 95% RH (non-condensing) |

| Installation method | DIN rail mount (35mm) |

| Dimensions | 120mm × 90mm × 65mm (4.72″ × 3.54″ × 2.56″) |

| Certifications | CE, UL, CUL, ATEX, IECEx, RoHS, TÜV SÜD certified |

| MTBF | >300,000 hours |

ABB EL3020

Product introduction

The ABB EL3020 is a high-performance safety I/O module designed to extend the input/output capabilities of industrial safety control systems. As a critical component in ABB’s safety automation ecosystem, this module provides reliable connectivity between safety sensors, actuators, and safety controllers like the ABB SUE3000, enabling the implementation of complex safety functions in hazardous industrial environments.

ABB EL3020 serves as a distributed safety I/O node that processes safety-related signals from field devices and executes safety outputs under the supervision of a safety controller. Its compact design and flexible configuration make it suitable for both centralized and distributed safety architectures, allowing system designers to place I/O modules close to field devices to reduce wiring costs and improve response times.

In modern safety automation systems, ABB EL3020 plays an essential role in expanding the reach of safety controllers while maintaining the highest levels of safety integrity. By providing secure, reliable connectivity for safety devices, this module helps ensure comprehensive monitoring and protection of personnel, equipment, and processes across a wide range of industrial applications, from manufacturing cells to large-scale process plants.

Core advantages and technical highlights

High safety integrity: ABB EL3020 achieves SIL 3 certification per IEC 61508 and PL e per ISO 13849-1, ensuring it can be used in the most demanding safety applications. The module incorporates advanced diagnostic features that continuously monitor input/output circuits, communication integrity, and internal hardware health, providing immediate fault detection and reporting. This self-monitoring capability ensures that potential failures are identified before they can compromise safety functions, maintaining high availability of the safety system.

Flexible I/O configuration: The module offers exceptional flexibility with 8 configurable safety inputs and 4 safety outputs arranged in 2 x 2-channel redundant groups. ABB EL3020 supports both NPN and PNP input types without hardware modifications, allowing seamless integration with various safety sensors including emergency stop buttons, safety interlocks, and light curtains. The redundant output configuration provides enhanced reliability for critical safety actions such as stopping hazardous machinery or isolating energy sources.

Rapid response performance: ABB EL3020 delivers exceptional speed with input processing times under 5 ms and output activation times under 8 ms, ensuring timely response to hazardous conditions. This rapid performance is crucial for applications involving fast-moving machinery where even small delays could result in accidents or equipment damage. The module’s deterministic behavior ensures consistent response times regardless of system load, maintaining predictable safety performance.

Seamless integration with safety controllers: Designed for plug-and-play integration with safety controllers like ABB SUE3000, ABB EL3020 uses PROFIsafe over Ethernet for secure communication. This standardized safety protocol ensures reliable data exchange between the module and controller while maintaining safety integrity. The module supports online configuration and diagnostics, allowing for easy system expansion or modification without disrupting operation, and simplifies integration into both new installations and existing safety systems.

Typical application scenarios

In automotive assembly plants, ABB EL3020 modules are deployed in robotic workcells to connect safety devices with the central ABB SUE3000 safety controller. Each module monitors multiple safety sensors including light curtains at cell entrances, emergency stop buttons, and interlock switches on safety gates. When a safety condition is detected, ABB EL3020 rapidly communicates with the safety controller and activates redundant output circuits to stop robotic motion and prevent access to hazardous areas. The module’s compact size allows installation in space-constrained robot cabinets, while its wide temperature range ensures reliable operation in factory environments.

Chemical processing facilities utilize ABB EL3020 to extend safety monitoring to remote process areas. The modules connect to gas detection sensors, pressure switches, and emergency isolation valve controls, communicating with a central ABB SUE3000 controller via PROFIsafe. In the event of a hazardous condition like a toxic gas leak or overpressure situation, ABB EL3020 provides immediate local indication while transmitting data to the safety controller for coordinated system-wide safety actions. The module’s rugged design withstands the harsh environmental conditions common in chemical plants, including temperature extremes and vibration.

Food and beverage manufacturing facilities employ ABB EL3020 to monitor safety functions on packaging lines and processing equipment. The modules connect to safety interlocks on machine guards, emergency stop buttons at operator stations, and metal detector safety outputs. ABB EL3020 interfaces with the ABB SUE3000 safety controller to ensure that hazardous machinery stops when guards are opened or other unsafe conditions are detected. The module’s diagnostic capabilities help maintenance teams quickly identify issues with safety devices, minimizing downtime while maintaining compliance with food safety regulations.

ABB EL3020

Related model recommendations

ABB SUE3000: Safety controller that supervises and coordinates ABB EL3020 modules in safety systems.

ABB GFD563A102 3BHE046836R0102: Ethernet communication module that supports network infrastructure for ABB EL3020 safety communications.

ABB EL3030: Complementary safety I/O module with 16 inputs and 8 outputs for larger safety applications alongside ABB EL3020.

ABB XFD213A 3BHE028122R0001: Fieldbus interface module that enables integration of ABB EL3020 with Profibus-based safety devices.

ABB XVC763A 3BHE036885R0102: Managed Ethernet switch that provides secure network connectivity for ABB EL3020 modules.

ABB S800 I/O system: Distributed I/O platform that can be used alongside ABB EL3020 for mixed standard and safety I/O applications.

ABB 3HAC031684-001: Rugged M12 cable assembly for reliable connections between safety sensors and ABB EL3020.

ABB CM572 3BSE013229R1: Communication module that facilitates integration of ABB EL3020 with legacy safety systems during upgrades.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing ABB EL3020, verify the mounting location provides protection from excessive moisture, vibration, and electromagnetic interference. Ensure the ambient temperature remains within the -25°C to +65°C operating range. Confirm the 24 VDC power supply delivers stable output with ripple voltage below 100mV and appropriate overcurrent protection. Use shielded twisted-pair cables for all safety connections, with shields grounded at both ends to maintain noise immunity. Mount the module on a clean 35mm DIN rail, ensuring proper spacing from other devices for adequate cooling. Plan network cabling to minimize electromagnetic interference, avoiding parallel runs with power cables.

Maintenance suggestions: Perform quarterly visual inspections of ABB EL3020 to check for secure connections, dust accumulation, and signs of physical damage. Review diagnostic data through the safety controller interface to monitor channel status, communication quality, and internal diagnostics. Test all connected safety functions semi-annually using ABB-recommended procedures to verify proper operation of inputs and outputs. When updating firmware, use ABB-approved software tools and follow strict change management processes to maintain safety certification. Replace any damaged cables or connectors immediately with ABB-approved components. In case of faults, utilize the module’s diagnostic indicators to isolate issues, ensuring safety functions remain operational during troubleshooting.

Service and guarantee commitment

ABB provides ABB EL3020 with a comprehensive 36-month warranty covering manufacturing defects and ensuring compliance with published safety performance specifications under normal operating conditions. Our global technical support network includes safety automation specialists who offer expert assistance for installation, configuration, and troubleshooting, ensuring proper integration with safety controllers like ABB SUE3000.

Customers gain access to ABB’s specialized safety knowledge resources, including application notes on safety I/O design, certification documentation, and training programs focused on functional safety implementation. Beyond the warranty period, ABB offers safety lifecycle services including periodic safety system audits, performance validation, and recertification support to maintain safety integrity throughout the product’s operational life. ABB’s commitment to safety excellence ensures that ABB EL3020 delivers reliable performance in critical safety applications, backed by our extensive experience in industrial safety automation.