Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

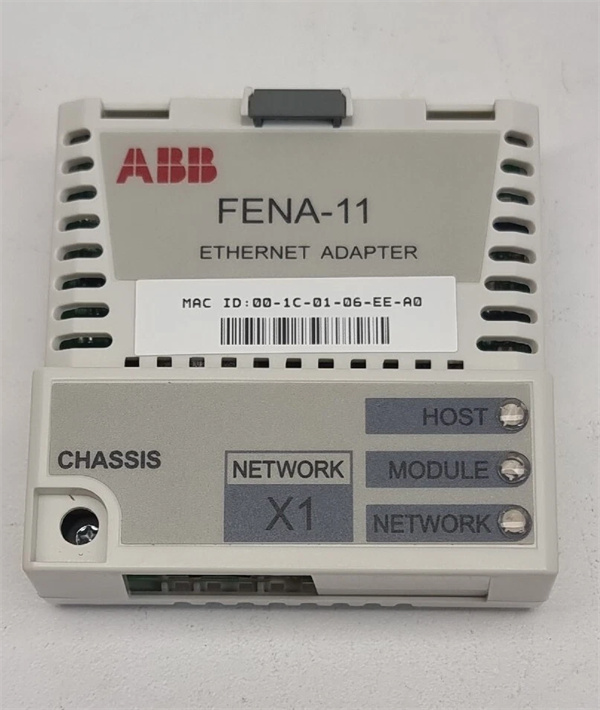

| Product model | FENA-11 |

| Manufacturer | ABB |

| Product category | Ethernet adapter for AC drives |

| Compatible systems | ABB ACS800, ACS880 series drives |

| Communication protocol | Ethernet/IP, Modbus TCP/IP |

| Data transfer rate | 10/100 Mbps (auto-negotiation) |

| Number of ports | 1×Ethernet port (RJ45) |

| Operating voltage | 24 V DC ±10% |

| Power consumption | ≤ 3 W |

| Operating temperature | -10°C to +60°C |

| Storage temperature | -40°C to +85°C |

| Dimensions (W×H×D) | 80 mm × 40 mm × 20 mm (approx.) |

| Weight | Approximately 0.05 kg |

| Installation method | Mounting on drive control board via connector |

| Protection class | IP20 |

| Compliance | CE, UL, IEEE 802.3 |

| Diagnostic features | LED indicators for link status, data transmission, and power |

| Connection type | Plug-in interface to drive control board |

| Isolation | 2.5 kV AC between Ethernet and drive circuits |

ABB FENA-11

Product introduction

The FENA-11 is a high-performance Ethernet adapter from ABB, specifically designed to enable seamless communication between ABB AC drives (such as ACS800 and ACS880 series) and industrial Ethernet networks. As a key connectivity component, it serves as a bridge, allowing drives to be integrated into Ethernet/IP and Modbus TCP/IP based automation systems, facilitating real-time monitoring, control, and configuration of drives.

This adapter integrates directly with the control board of compatible ABB drives, eliminating the need for complex wiring and external enclosures. The FENA-11 supports both Ethernet/IP and Modbus TCP/IP protocols, making it highly versatile for connecting drives to various industrial control systems, including SCADA, HMI, and PLCs like ABB’s AC800M.

Built with industrial-grade components, the FENA-11 operates reliably in harsh industrial environments, withstanding temperature fluctuations and electromagnetic interference. Its compact design and easy installation make it an essential component for modernizing drive communication, enabling remote access and reducing the need for on-site drive configuration. Unlike the DO910 which focuses on digital output control, the FENA-11 specializes in network communication, enhancing the connectivity of drive systems.

Core advantages and technical highlights

Dual-protocol support

The FENA-11 supports both Ethernet/IP and Modbus TCP/IP, providing flexibility to integrate ABB drives into diverse industrial networks. In a manufacturing facility using Rockwell Automation’s Ethernet/IP system, it enables seamless communication between ACS880 drives and the control system. In a plant with Modbus TCP/IP infrastructure, it allows the same drives to connect without additional hardware, reducing inventory and training costs compared to single-protocol adapters.

High-speed data transfer

With 10/100 Mbps auto-negotiation, the FENA-11 ensures fast and reliable data transmission, enabling real-time monitoring of drive parameters (e.g., speed, current, torque) and rapid response to control commands. This high speed is crucial in applications like conveyor systems, where precise synchronization of multiple drives is required, ensuring smooth operation and reducing product jams.

Easy integration and configuration

The FENA-11 mounts directly on the drive’s control board via a plug-in connector, eliminating the need for external wiring harnesses. Configuration is simplified through ABB’s Drive composer software, which allows users to set IP addresses, select protocols, and map drive parameters to network variables. This plug-and-play functionality reduces installation time by up to 50% compared to external communication modules, minimizing downtime during retrofits.

Enhanced diagnostics and remote monitoring

Equipped with LED indicators for link status, data transmission, and power, the FENA-11 provides quick visual feedback on network connectivity. It also supports advanced diagnostic functions, such as drive fault reporting over the network, enabling maintenance teams to identify issues remotely without accessing the drive cabinet. This remote monitoring capability is invaluable in facilities with drives located in hazardous or hard-to-reach areas, improving safety and reducing troubleshooting time.

Typical application scenarios

In a wastewater treatment plant, the FENA-11 is used to connect ACS800 drives controlling pump motors to a Modbus TCP/IP SCADA system. The adapter enables the SCADA system to monitor pump speed, current, and temperature in real-time, and send speed setpoint commands to adjust flow rates based on water levels measured by sensors connected to the AI810 3BSE008516R1 module.

If a pump motor experiences an overload, the FENA-11 transmits the fault code to the SCADA system, which triggers an alarm and activates a backup pump via the DO910 digital output module. This integrated system ensures continuous operation and minimizes downtime.

In an automotive assembly line, multiple ACS880 drives with FENA-11 adapters are connected to an Ethernet/IP network. The adapters enable the Rockwell PLC to synchronize drive speeds for conveyor belts, robotic arms, and paint sprayers, ensuring precise timing and reducing production errors. Maintenance technicians use remote access via the Ethernet network to adjust drive parameters and perform diagnostics, reducing the need for line shutdowns.

ABB FENA-11

Related model recommendations

- FENA-21: An advanced Ethernet adapter with additional features like PROFINET support, suitable for plants requiring PROFINET connectivity alongside Ethernet/IP and Modbus TCP/IP.

- DO910: A digital output module that works with the FENA-11-connected drives, activating auxiliary equipment (e.g., alarms, valves) based on drive status.

- AI810 3BSE008516R1: An analog input module that monitors process variables (e.g., pressure, level) which are used to adjust drive setpoints via the FENA-11

- CI810B 3BSE020520R: A Profibus DP module that, when used with the FENA-11in a hybrid network, enables communication between drives and Profibus-based controllers.

- ACS880-01-04A1-3: An ABB AC drive compatible with the FENA-11, providing 1.5 kW power for small to medium-sized industrial applications.

- 3BHE009017R0102: A power supply module that provides stable 24 V DC to the drive control board, ensuring reliable operation of the FENA-11.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the FENA-11, ensure the drive is powered off and disconnected from the mains. The ambient temperature around the drive should be within -10°C to +60°C, and the relative humidity should not exceed 95% (non-condensing). Required tools include a screwdriver and ESD protection equipment (wristband, mat) to prevent damage to sensitive electronics.

Locate the communication slot on the drive’s control board (refer to the drive manual for specific position). Align the FENA-11 with the slot and gently press it into place until it clicks securely. Connect an Ethernet cable (Cat5e or higher, shielded) from the adapter’s RJ45 port to the network switch, ensuring the cable is routed away from high-voltage cables to minimize interference.

Commissioning steps

After physical installation, power on the drive. The FENA-11‘s power LED should illuminate, followed by the link LED once a network connection is established. Launch ABB’s Drive composer software and connect to the drive via the network. Configure the adapter’s IP address (static or DHCP), subnet mask, and gateway to match the network requirements.

Select the desired protocol (Ethernet/IP or Modbus TCP/IP) and map drive parameters (e.g., actual speed, reference speed) to network variables. Test communication by reading drive status and sending a start/stop command. Verify that data is transmitted correctly and that there are no errors in the network diagnostics.

Maintenance suggestions

For daily maintenance, check the FENA-11‘s LEDs: a steady green power LED, link LED, and flashing data LED indicate normal operation. A red or off LED signals issues (e.g., network disconnection, power loss)—check the Ethernet cable, switch port, and drive power.

Inspect the Ethernet cable and connector quarterly for damage, corrosion, or loose connections, which can cause communication interruptions. Clean the adapter and drive control board with compressed air to remove dust; avoid using liquids or abrasive materials.

Update the FENA-11 firmware annually using Drive composer to ensure compatibility with the latest network protocols and security patches. If communication issues persist after troubleshooting, replace the adapter with an ABB-approved spare, ensuring it is configured with the same network settings as the original.

Service and guarantee commitment

The FENA-11 is backed by ABB’s 2-year warranty, covering defects in materials and workmanship under normal operating conditions. During the warranty period, ABB will repair or replace faulty adapters at no cost, minimizing downtime for drive systems.

ABB’s technical support team provides 24/7 assistance for installation, configuration, and troubleshooting, including guidance on integrating the FENA-11 with ACS800/ACS880 drives, Ethernet networks, and complementary modules like the DO910 and AI810 3BSE008516R1. We offer detailed network configuration guides and compatibility matrices to ensure optimal performance.

Extended service contracts are available, including on-site network testing, priority support, and firmware updates. ABB’s global service network ensures fast delivery of replacement adapters, reducing the impact of failures on critical drive applications. Trust the FENA-11 to deliver reliable Ethernet connectivity for ABB drives, backed by ABB’s expertise in industrial automation and drive technology.