Description

- ••

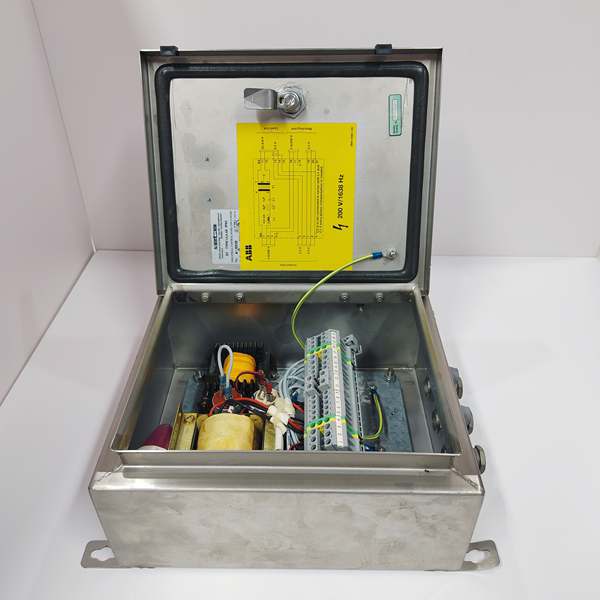

Model Number: FFVO142 - ••

Order Number: 3BSE223732R0001 - ••

Manufacturer: ABB - ••

Product Type: Foundation Fieldbus H1 Interface Module - ••

Compatible System: S800 I/O, System 800xA - ••

Fieldbus Protocol: Foundation Fieldbus H1 (IEC 61158-2) - ••

H1 Data Rate: 31.25 kbit/s - ••

Link Master: Yes, with Link Active Scheduler (LAS) capability - ••

Power Conditioning: Integrated, for fieldbus segment - ••

Power Supply: 24V DC via S800 I/O baseplate - ••

Fieldbus Power: Provides power to the fieldbus segment - ••

Isolation: 500V AC between field and system side - ••

Connectors: Fieldbus terminal block - ••

Number of Segments: 1 H1 segment per module - ••

Max Devices per Segment: Up to 32 devices (theoretical, practical limit depends on power) - ••

Operating Temperature: -25°C to +70°C - ••

Certifications: ATEX, IECEx, FM, CSA (for hazardous areas) ABB FFVO142 3BSE223732R0001