Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | FI810F 3BDH000030R1 |

| Manufacturer | ABB |

| Product category | Digital input module (Advant OCS / Symphony Plus system) |

| Number of channels | 16 digital inputs |

| Input type | 24 V DC (sinking/sourcing, configurable) |

| Input voltage range | 15-30 V DC |

| Input current | 3 mA (typical at 24 V DC) |

| Response time | ≤ 1 ms (standard); configurable up to 100 ms |

| Isolation | 2.5 kV AC (channel-to-bus, channel-to-channel) |

| Operating temperature | -40°C to +70°C |

| Dimensions (W×H×D) | 22 mm × 105 mm × 115 mm |

| Installation method | DIN rail mounting via TB820 terminal base |

| Diagnostic features | Open circuit detection, short circuit protection, channel status LEDs |

| Compliance | IEC 61131-2, CE, UL 508, RoHS |

| Compatible systems | ABB Symphony Plus DCS, Advant OCS, AC400 controller, SD834 safety modules |

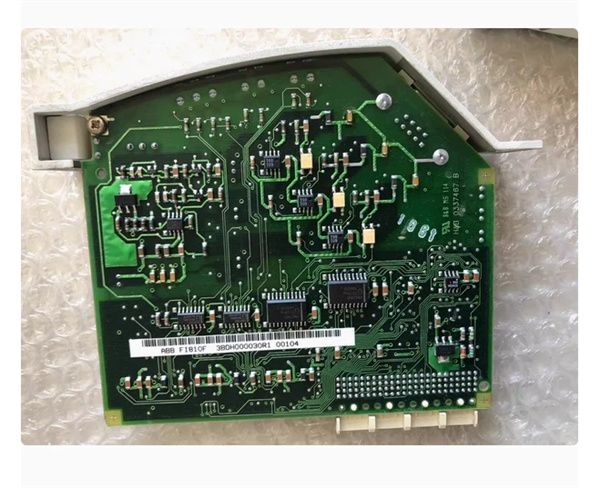

ABB FI810F 3BDH000030R1

Product introduction

The FI810F 3BDH000030R1 is a high-performance digital input module from ABB, designed to monitor discrete signals in industrial automation and control systems. As a key component of ABB’s Advant OCS and Symphony Plus portfolios, it serves as the interface between field devices (such as limit switches, proximity sensors, and pushbuttons) and the control layer, converting physical switch states into digital data for processing by controllers.

With 16 configurable channels supporting both sinking and sourcing inputs, FI810F 3BDH000030R1 offers flexibility for diverse wiring scenarios. Its fast response time (≤1 ms) ensures real-time monitoring of time-critical signals, while 2.5 kV isolation protects the control system from electrical noise and ground loops. Whether deployed in power generation, chemical processing, or manufacturing, FI810F 3BDH000030R1 delivers reliable signal acquisition, enhancing the accuracy and efficiency of industrial processes.

Core advantages and technical highlights

High channel density

FI810F 3BDH000030R1 packs 16 channels into a 22 mm-wide module, maximizing cabinet space utilization. In a power plant’s turbine control panel, this density allows monitoring of 16 discrete signals (e.g., valve positions, bearing temperature alarms) without expanding the cabinet footprint, reducing installation costs.

Flexible input configuration

Support for both sinking and sourcing inputs eliminates the need for module replacements when wiring schemes change. In a food packaging line, this adaptability lets the same FI810F 3BDH000030R1 module connect to NPN proximity sensors (sinking) and PNP photoelectric sensors (sourcing), simplifying inventory management and reducing spare parts stock.

Robust signal integrity

2.5 kV AC isolation between channels and the system bus ensures stable operation in electrically noisy environments. In a steel mill, where arc furnaces generate significant EMI, FI810F 3BDH000030R1 maintains accurate signal detection from conveyor limit switches, preventing false alarms that could disrupt production.

Typical application scenarios

In a combined cycle power plant, FI810F 3BDH000030R1 is integrated into the boiler control system:

- Monitors 16 discrete signals, including flame detector status, damper position switches, and fuel valve limit switches.

- Transmits data to the Symphony Plus DCS, enabling operators to track equipment status in real time.

- Works alongside SD834safety modules, providing non-safety input data that complements safety-critical signals for comprehensive boiler monitoring.

The module’s -40°C to +70°C operating range ensures reliability in the plant’s harsh environment, where temperature fluctuations are common near boilers and turbines.

In a semiconductor fabrication facility, FI810F 3BDH000030R1 monitors cleanroom equipment:

- Tracks door interlock status, vacuum pump readiness, and wafer handling robot position sensors.

- Its fast response time (≤1 ms) ensures immediate detection of equipment faults, triggering alerts via the control system to minimize downtime.

- Configurable input filters reduce noise from nearby high-frequency equipment, ensuring accurate signal detection in sensitive semiconductor processes.

ABB FI810F 3BDH000030R1

Related model recommendations

- FO810F: 16-channel digital output module that complements FI810F 3BDH000030R1in I/O systems, controlling actuators based on input signals.

- AI810: Analog input module paired with FI810F 3BDH000030R1for mixed-signal monitoring (e.g., temperature + limit switches).

- TB820: Terminal base required for FI810F 3BDH000030R1mounting, with secure screw terminals for field wiring.

- SD834: Safety I/O module that works with FI810F 3BDH000030R1in systems requiring both standard and safety-related inputs.

- AC400: ABB controller that processes digital signals from FI810F 3BDH000030R1to execute control logic.

- CI854A: Ethernet/IP communication module enabling remote monitoring of FI810F 3BDH000030R1

- FI820F: 32-channel variant of FI810F 3BDH000030R1for large-scale digital input monitoring.

- 1SVR011700R0000: 24 V DC power supply providing stable voltage to FI810F 3BDH000030R1and connected sensors.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing FI810F 3BDH000030R1, power off the I/O rack and verify the installation area is clean and dry. Mount the TB820 terminal base on a 35 mm DIN rail, leaving 20 mm clearance for airflow. Use 0.5-2.5 mm² shielded cables for field wiring, separating input wiring from power cables to reduce noise. Connect field devices to terminals 1-32 (channels 1-16, each with positive and common connections), verifying polarity for 24 V DC signals. Torque terminal screws to 0.6 Nm, and label wires clearly per the system diagram. Power the module via the I/O backplane, ensuring 24 V DC supply is within ±10% tolerance.

Maintenance suggestions

Daily checks of FI810F 3BDH000030R1 involve verifying green power LED and channel activity LEDs (illuminated when input is active); red LEDs indicate faults like short circuits. Test input channels monthly using a signal generator, confirming response times meet application requirements. Inspect terminal connections quarterly for corrosion or looseness, tightening as needed. If a channel fails, swap the sensor to a spare channel to isolate issues—replace FI810F 3BDH000030R1 with an ABB-approved spare if internal faults are confirmed, ensuring the replacement module is configured with matching input parameters.

Service and guarantee commitment

The FI810F 3BDH000030R1 is backed by a 3-year warranty, covering defects in materials and workmanship under normal operating conditions. ABB’s technical support team provides guidance on integration with Symphony Plus and Advant OCS systems, including configuration of input filters and diagnostic settings.

Customers receive access to detailed wiring diagrams, commissioning guides, and troubleshooting resources specific to FI810F 3BDH000030R1. ABB offers on-site training for maintenance personnel, ensuring proper handling and maximization of module performance. With global distribution centers, replacement modules are readily available to minimize downtime in critical applications. Trust FI810F 3BDH000030R1 for reliable digital input monitoring, backed by ABB’s expertise in industrial control systems.