Description

Detailed parameter table

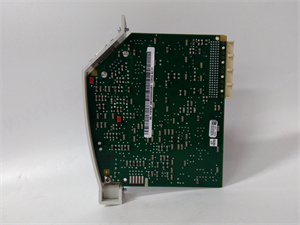

| Parameter name | Parameter value |

| Product model | FI830F |

| Manufacturer | ABB |

| Product category | Analog Input Module (Industrial I/O Module) |

| Input channels | 8 channels (isolated) |

| Input type | Current (4-20 mA), Voltage (0-10 V, 0-5 V, ±10 V) (configurable per channel) |

| Measurement range | 4-20 mA (corresponding to 0-100% process value), 0-10 V (0-100% process value) |

| Accuracy | ±0.1% of full scale (typical), ±0.2% of full scale (maximum) |

| Resolution | 16-bit |

| Sampling rate | 100 Hz per channel (simultaneous sampling) |

| Isolation rating | 2.5 kVrms (channel to channel, channel to backplane) |

| Communication | Backplane communication with PLC processor (AC500 series compatible) |

| Operating voltage | 24 VDC ±20% (from backplane) |

| Power consumption | 3 W typical, 5 W maximum |

| Operating temperature | -25°C to +70°C (-13°F to +158°F) |

| Humidity tolerance | 5% to 95% RH (non-condensing) |

| Mounting method | Backplane mount (AC500 series racks) |

| Dimensions | 100mm × 160mm × 30mm (3.94″ × 6.30″ × 1.18″) |

| Certifications | CE, UL, cUL, ATEX, IECEx, RoHS, IEC 61131-2 |

| MTBF | >600,000 hours |

ABB FI830F

Product introduction

The ABB FI830F is a high-performance analog input module designed as a key component in industrial automation I/O systems. As part of ABB’s AC500 series of I/O modules, this device specializes in converting analog signals from industrial sensors and instruments into digital data that can be processed by programmable logic controllers (PLCs). Its 8-channel design with per-channel configurability makes it highly versatile for capturing various process variables in manufacturing, energy, and infrastructure applications.

ABB FI830F serves as the critical interface between analog field devices—such as pressure transmitters, temperature sensors, flow meters, and level indicators—and the digital control system. By accurately converting continuous physical measurements into digital values, it enables the ABB PM865K01 3BSE031151R1 PLC to monitor, analyze, and control industrial processes with precision. The module’s robust isolation and noise immunity ensure reliable operation even in electrically harsh industrial environments where electromagnetic interference is common.

In modern automation architectures, ABB FI830F integrates seamlessly with the PM865K01 processor, expanding the PLC’s capability to interface with analog sensors. This combination creates a powerful measurement and control system that captures real-time process data, enabling closed-loop control, process optimization, and predictive maintenance strategies across diverse industrial applications.

Core advantages and technical highlights

High-precision measurement: ABB FI830F delivers exceptional measurement accuracy of ±0.1% of full scale, ensuring reliable capture of subtle process variations. Its 16-bit resolution provides 65,536 discrete values across the input range, enabling precise detection of small changes in sensor signals—critical for applications like quality control in manufacturing or precise dosing in chemical processes. The module’s low temperature drift (<50 ppm/°C) ensures measurement stability even as environmental conditions fluctuate.

Flexible input configuration: Each of the 8 channels on ABB FI830F can be independently configured for either current (4-20 mA) or voltage (0-10 V, 0-5 V, ±10 V) inputs, providing unmatched flexibility for connecting various analog sensors and transmitters. This eliminates the need for multiple specialized modules, reducing inventory requirements and simplifying system design. The module automatically recognizes configured input types, with settings stored in non-volatile memory that persists through power cycles.

Advanced signal conditioning: The module incorporates sophisticated signal conditioning circuitry that filters noise and stabilizes input signals before conversion. ABB FI830F features high common-mode rejection ratio (CMRR >100 dB at 50/60 Hz) and high isolation (2.5 kVrms) between channels and from field devices to the backplane, preventing ground loops and interference from affecting measurements. This robust design ensures accurate data acquisition even in environments with heavy motor loads, variable frequency drives, or other noise sources.

Efficient data acquisition: With a simultaneous sampling rate of 100 Hz per channel, ABB FI830F captures dynamic process changes with sufficient speed for most industrial applications while minimizing data bandwidth requirements. The module buffers measurement data and communicates with the PM865K01 PLC via the backplane, ensuring deterministic data transfer with minimal latency. This efficient data acquisition enables real-time process monitoring and control without overloading the PLC’s processing resources.

Typical application scenarios

In chemical processing plants, ABB FI830F modules connect to pressure, temperature, and level sensors throughout reaction vessels and piping systems. The module converts analog signals from these sensors into digital data that the PM865K01 PLC uses to implement closed-loop control of heating, cooling, and mixing processes. For example, in batch reactors, FI830F captures temperature profiles with high precision, enabling the PLC to adjust heating elements to maintain precise reaction temperatures—critical for product quality and safety. The module’s channel isolation prevents cross-talk between sensitive measurements in corrosive or hazardous environments.

Manufacturing facilities utilize ABB FI830F to monitor key process variables in production lines, such as tension in rolling mills, pressure in hydraulic systems, or flow rates in material handling. The module connects to analog sensors on machinery, providing the PM865K01 PLC with real-time data for process optimization. In automotive assembly, for instance, FI830F measures torque in robotic welding arms and pressure in pneumatic actuators, enabling the PLC to adjust parameters for consistent product quality. The module’s high accuracy ensures detection of subtle process drifts before they result in defects.

Water and wastewater treatment plants deploy ABB FI830F to monitor flow rates, pH levels, turbidity, and chemical dosing rates. The module converts signals from analytical sensors and flow meters, providing the PM865K01 PLC with the data needed to optimize treatment processes. For example, in filtration systems, FI830F measures differential pressure across filters, allowing the PLC to schedule backwashing cycles precisely when needed—reducing water waste while maintaining treatment efficiency. The module’s wide operating temperature range ensures reliable operation in both outdoor pump stations and indoor control rooms.

ABB FI830F

Integration with PM865K01 PLC

ABB FI830F forms an integral part of the AC500 automation system when paired with the PM865K01 3BSE031151R1 PLC:

Backplane communication: The FI830F installs directly in the same AC500 rack as the PM865K01, communicating via the high-speed backplane bus for low-latency data transfer. This integration eliminates the need for external wiring between the I/O module and processor, simplifying installation and reducing potential failure points.

Configuration synergy: Both devices are configured using ABB’s Automation Builder software, with seamless parameter transfer between the PLC program and I/O module settings. This unified configuration environment ensures consistent scaling, calibration, and alarm thresholds between the FI830F’s hardware configuration and the PM865K01’s control logic.

Data processing workflow: FI830F preprocesses analog data (filtering, scaling) before sending it to the PM865K01, reducing the PLC’s computational load. The PLC can then focus on control algorithms and decision-making using the pre-validated data from the FI830F, improving overall system responsiveness.

Diagnostic integration: The module reports detailed diagnostic information (channel faults, overrange conditions, communication errors) to the PM865K01, which logs and acts on these alerts. This integrated diagnostics capability enables rapid troubleshooting of sensor or wiring issues, minimizing downtime.

Related model recommendations

ABB PM865K01 3BSE031151R1: PLC processor that forms the core of the automation system with FI830F.

ABB DI810: Digital input module that complements FI830F for discrete signal acquisition.

ABB DO810: Digital output module for control applications alongside FI830F’s measurement capabilities.

ABB AO810: Analog output module that works with FI830F to create complete analog I/O systems.

ABB AC500 Rack: Backplane enclosure that houses FI830F and PM865K01 in a integrated system.

ABB 1TGE120011R1001: Circuit breaker that provides electrical protection for FI830F-based I/O systems.

ABB CP600 HMI: Operator interface that visualizes process data acquired by FI830F and PM865K01.

ABB 3HAC031684-001: Shielded cable assembly for reliable sensor connections to FI830F.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing ABB FI830F, verify compatibility with the AC500 series rack and ensure the mounting environment remains within the -25°C to +70°C temperature range. Power down the AC500 rack before inserting the module into the designated slot, ensuring proper alignment with the backplane connector. Connect field devices using shielded twisted-pair cables, with cable shields grounded at both ends to maximize noise immunity. For current loop sensors, ensure proper wiring polarity and verify that external power supplies for 4-wire transmitters are correctly connected.

Commissioning steps: After physical installation, power up the AC500 system and verify the PM865K01 recognizes the FI830F module via the Automation Builder software. Configure each channel’s input type (current/voltage) and range using the software tools, matching settings to the connected sensors. Calibrate the module if necessary using known reference signals, though factory calibration typically ensures accuracy for most applications. Test each channel with a signal generator or known sensor input to verify correct operation, checking that values displayed in the PLC program match expected measurements.

Maintenance suggestions: Perform quarterly visual inspections of ABB FI830F to check for secure backplane connections and signs of overheating. Monitor diagnostic data in the PM865K01 for channel faults, drift alerts, or communication errors that may indicate sensor issues or module degradation. Clean dust from the module’s ventilation slots annually using compressed air (maximum 5 bar) to prevent overheating. When replacing sensors, verify that new devices match the configured input type and range for their respective channels. During system-wide maintenance, recalibrate the module using traceable standards to maintain measurement accuracy, particularly in critical applications.

Service and guarantee commitment

ABB provides ABB FI830F with a comprehensive 36-month warranty covering manufacturing defects and ensuring compliance with published performance specifications under normal operating conditions. Our global technical support network includes specialists in industrial I/O systems who offer expert assistance for configuration, troubleshooting, and system integration with PLCs like the PM865K01 3BSE031151R1.

Customers receive access to technical resources including wiring diagrams, configuration guides, and application notes for optimizing FI830F performance with various sensor types. Beyond the warranty period, ABB offers calibration services using traceable standards, replacement parts, and technical training to ensure ongoing accuracy and reliability. ABB’s commitment to quality ensures that ABB FI830F delivers precise analog data acquisition in critical automation applications, backed by our extensive experience in industrial measurement and control systems.