Description

Detailed parameter table

| Parameter name | Parameter value |

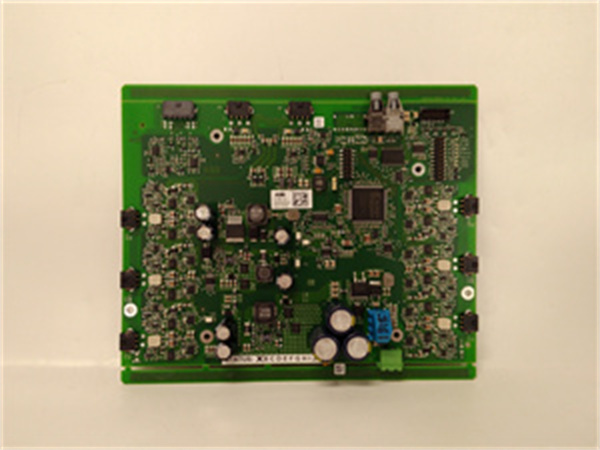

| Product model | GCC960C103 |

| Manufacturer | ABB |

| Product category | Industrial communication gateway module |

| Supported protocols | PROFINET IO, EtherNet/IP, Modbus TCP/IP, PROFIBUS DP, OPC UA |

| Communication interfaces | 4 x Gigabit Ethernet (RJ45), 2 x PROFIBUS DP (D-sub 9), 1 x USB 3.0 |

| Data transfer rate | Up to 1 Gbps (Ethernet), 12 Mbps (PROFIBUS DP) |

| Concurrent connections | Up to 64 (client/server) |

| Operating temperature | -40°C to 70°C |

| Power supply | 24 V DC ±15% |

| Power consumption | Max 12 W |

| Protection rating | IP20 |

| Mounting type | Backplane mount (compatible with AC800M/S800 series) |

| Dimensions | 140mm × 180mm × 90mm |

| Certifications | CE, UL, ATEX, IEC 61131-2, PROFINET Certified |

ABB GCC960C103

Product introduction

The GCC960C103 is a high-performance industrial communication gateway module from ABB, designed to facilitate seamless data exchange between diverse automation systems and protocols. As a pivotal component in ABB’s industrial networking portfolio, this gateway acts as a universal translator, enabling interoperability between legacy and modern systems—such as connecting PROFIBUS DP devices to PROFINET IO controllers like the CI930F 3BDH001010R0005 or linking EtherNet/IP sensors to ABB’s 3BHE024577R0101 PPC907BE AMC34 processor module.

Unlike single-protocol gateways, the GCC960C103 supports multiple industrial protocols simultaneously, making it ideal for brownfield upgrades and mixed-network environments. Whether deployed in process plants with aging PROFIBUS infrastructure or smart factories adopting Industry 4.0 standards, this module ensures reliable data flow across the entire automation ecosystem, enhancing visibility and control.

Core advantages and technical highlights

Multi-protocol interoperability: The GCC960C103 natively supports PROFINET IO, EtherNet/IP, Modbus TCP/IP, PROFIBUS DP, and OPC UA, eliminating the need for multiple specialized gateways. In an automotive plant transitioning from PROFIBUS to PROFINET, it can simultaneously bridge 20 PROFIBUS-based motor drives with a new PROFINET-enabled PLC, while translating data to OPC UA for MES integration—reducing integration costs by up to 40%.

High-speed data routing: With Gigabit Ethernet interfaces and 12 Mbps PROFIBUS support, the gateway handles large-volume data transfers with sub-10 ms latency, critical for time-sensitive applications like real-time process control. In a chemical plant, this ensures pressure readings from UAD155A0111 3BHE029110R0111 analog modules (transmitted via Modbus TCP) are routed to the control system within 5 ms, enabling rapid adjustments to reactor conditions.

Robust security features: Equipped with role-based access control (RBAC), secure shell (SSH) encryption, and protocol-specific security mechanisms (e.g., PROFINET IO security), the GCC960C103 protects against unauthorized access and data tampering. In a water treatment facility, this prevents malicious interference with pump control signals routed between the SCADA system and field devices, ensuring compliance with critical infrastructure security standards.

Redundant and fault-tolerant design: The gateway supports dual Ethernet ports for network redundancy, with automatic failover in <50 ms to prevent data loss during network outages. Its wide operating temperature range (-40°C to 70°C) and 2.5 kV AC isolation between interfaces ensure reliability in harsh environments—from freezing food processing plants to high-temperature steel mills.

Scalable configuration: Using ABB’s Gateway Configurator software, users can define custom data mappings, protocol conversions, and filtering rules to optimize bandwidth usage. In a logistics warehouse, this allows the gateway to prioritize real-time conveyor status data (from DSDP140B modules) over non-critical inventory updates, ensuring network efficiency even with 64 concurrent connections.

Typical application scenarios

In a pulp and paper mill, the GCC960C103 integrates three distinct systems: a legacy PROFIBUS DP network controlling paper machines, a PROFINET IO network managing drying ovens (via CI930F controllers), and an EtherNet/IP-based quality control system with vision sensors. The gateway translates speed setpoints from the PROFINET PLC to PROFIBUS drives, while routing quality data (via OPC UA) to the PPC907BE AMC34 processor for analysis. Its redundant Ethernet ports ensure uninterrupted communication during network maintenance, preventing costly production stoppages.

In a pharmaceutical manufacturing facility, the gateway connects a Modbus TCP-based environmental monitoring system (tracking temperature/humidity via UAD155A0111 modules) to a PROFINET IO safety system (including SNAT634PAC controllers). It enforces data integrity through encryption, ensuring compliance with FDA 21 CFR Part 11 requirements for electronic records. The gateway’s diagnostic features alert maintenance teams to communication delays, enabling proactive resolution before they impact batch quality.

ABB GCC960C103

Related model recommendations

GCC950C102: A compact variant with 2 Ethernet ports, ideal for small-scale protocol conversion.

CI930F 3BDH001010R0005: ABB’s PROFINET IO controller that integrates with the GCC960C103 for network expansion.

3BHE024577R0101 PPC907BE AMC34: ABB’s processor module that receives translated data via the gateway.

UAD155A0111 3BHE029110R0111: ABB’s analog input module whose data is routed through the GCC960C103.

PPD513A25-111615 3BHE039724R2565: ABB’s power distribution module that supplies redundant power to the gateway.

XC208: ABB’s managed switch that enhances network redundancy when paired with the GCC960C103.

HMI80: ABB’s touchscreen panel that visualizes gateway status and protocol traffic for operators.

Installation, commissioning and maintenance instructions

Installation preparation: Mount the GCC960C103 into a compatible S800 backplane, securing with front-panel screws (torque to 0.8 Nm). Ensure 100mm clearance for ventilation. Connect redundant 24 V DC power (via PPD513A25-111615) using 1.5mm² shielded cable, with 3A fuses per input. Attach network cables: Cat 6a for Ethernet (max 100m), shielded twisted-pair for PROFIBUS (100Ω impedance). Ground all shields at the gateway end. Required tools: torque screwdriver, wire strippers, network cable tester. Power off systems during installation.

Commissioning steps: Use ABB’s Gateway Configurator to define protocol mappings (e.g., map PROFIBUS DP register 40001 to PROFINET IO input 0x100). Configure IP addresses, subnet masks, and security settings (e.g., SSH keys). Test data routing by sending test signals from connected devices (e.g., a UAD155A0111 module) and verifying reception at the target system. Validate redundancy by disconnecting the primary Ethernet cable and confirming failover to the secondary port within 50 ms. Save configurations to non-volatile memory and export a backup.

Maintenance suggestions: Inspect quarterly for loose connections, dust, and LED status (power: green, Ethernet: flashing green, faults: red). Clean ventilation with compressed air. Monitor network traffic monthly via the web interface, checking for packet loss (>1% indicates issues). Update firmware annually via USB or Ethernet (with password protection) to address protocol updates. Test redundancy failover semi-annually. If communication errors persist, verify cable integrity and protocol settings before replacing with an ABB-certified unit.

Service and guarantee commitment

The GCC960C103 comes with a 5-year warranty from installation, covering manufacturing defects and protocol compliance. ABB guarantees 4-hour technical support response for critical applications, with on-site troubleshooting available in 72 hours. The module includes 3 years of free firmware updates and access to ABB’s protocol compatibility database. Extended contracts offer annual network audits, priority support, and on-site training, ensuring optimal performance over its 15-year design lifespan. Customers receive dedicated resources: wiring diagrams, protocol mapping guides, and troubleshooting videos.