Description

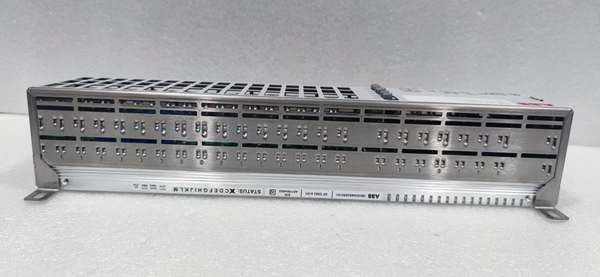

GFD563A101 3BHE046836R0101: Product Overview

The ABB GFD563A101 3BHE046836R0101 is a high-performance excitation device control unit designed for ABB’s AC 800PEC series of industrial automation controllers. As a critical component in power generation systems, it enables precise control of generator excitation, ensuring stable voltage output, optimal reactive power management, and enhanced system reliability.

Role in Automation Systems:

Positioned as the “brain” of the excitation system, the GFD563A101 acts as an interface between the AC 800PEC DCS and field devices (e.g., voltage regulators, current transformers, power sensors). It performs three primary functions:

-

Voltage Regulation: Monitors generator terminal voltage and adjusts excitation current to maintain setpoints, compensating for load changes or grid disturbances.

-

Reactive Power Control: Regulates reactive power output to support grid stability, preventing voltage collapse or overvoltage conditions.

-

Fault Diagnosis: Detects anomalies (e.g., overcurrent, overvoltage, communication failures) and triggers protective actions to avoid equipment damage.

Core Functionality:

-

Real-Time Signal Processing: Processes analog/digital signals from field devices (e.g., 4–20 mA current transformers, 0–10 V voltage sensors) with high precision, ensuring accurate control decisions.

-

Flexible Configuration: Supports customizable control algorithms (e.g., PID, adaptive control) via ABB’s engineering tools, adapting to different generator types (steam, hydro, gas) and operational requirements.

-

Communication Integration: Interfaces with the AC 800PEC DCS via Ethernet/RS-485, enabling remote monitoring and configuration from the control room.

Platform Benefits (AC 800PEC Series):

The GFD563A101 leverages ABB’s AC 800PEC platform, which is renowned for:

-

Scalability: Supports expansion with additional I/O modules or communication interfaces to accommodate growing power plant needs.

-

Reliability: Industrial-grade components and redundant design ensure 24/7 operation in harsh environments (e.g., high temperature, vibration).

-

Ease of Use: Compatible with ABB’s Control Builder M programming tool, reducing setup time and effort for engineers.

ABB GFD563A101 3BHE046836R0101

Technical Specifications

Model Number: GFD563A101 3BHE046836R0101

Manufacturer: ABB

Product Type: Excitation Device Control Unit

-

System Compatibility: ABB AC 800PEC DCS

-

Input Signals: 4–20 mA (current), 0–10 V (voltage), digital (status signals)

-

Output Signals: 4–20 mA (excitation current), 0–10 V (control signals), digital (actuator commands)

-

Control Algorithms: PID, adaptive control, custom logic (via Control Builder M)

-

Communication Interfaces: Ethernet (10/100 Mbps), RS-485 (Modbus RTU)

-

Operating Temperature: -20°C to +70°C (-4°F to 158°F)

-

Storage Temperature: -40°C to +85°C (-40°F to 185°F)

-

Humidity: 5% to 95% non-condensing

-

Dimensions (W×H×D): 210 mm × 160 mm × 50 mm (8.27 in × 6.30 in × 1.97 in)

-

Weight: 1.5 kg (3.31 lbs)

-

Certifications: CE, UL (inferred from ABB’s industrial product standards)

Core Features & Customer Value

1. Precise Voltage Regulation:

The GFD563A101’s real-time signal processing and adaptive control algorithms ensure generator terminal voltage stays within ±0.5% of setpoints, even under dynamic load conditions. This stability is critical for power plants to comply with grid codes and maintain customer satisfaction.

2. Reactive Power Optimization:

By regulating reactive power output, the module helps power plants reduce transmission losses and support grid stability. For example, in a thermal power plant, the GFD563A101 can adjust excitation current to compensate for reactive power demand from nearby industrial loads, preventing voltage drops.

3. Fault Diagnosis & Protection:

The module’s built-in diagnostic tools detect faults (e.g., overcurrent, overvoltage, communication failures) and trigger protective actions (e.g., tripping the excitation system, alerting operators). This reduces downtime and maintenance costs, ensuring continuous power generation.

4. Flexible Configuration:

With support for custom control algorithms via ABB’s Control Builder M, the GFD563A101 adapts to different generator types and operational requirements. For instance, a hydroelectric plant can use the module to implement a water-level-based excitation control strategy, optimizing turbine efficiency.

ABB GFD563A101 3BHE046836R0101

Typical Applications

The ABB GFD563A101 3BHE046836R0101 is widely used in power generation applications:

-

Thermal Power Plants:

-

Controls excitation systems for steam turbines, regulating voltage and reactive power to maintain grid stability.

-

Example: In a coal-fired power plant, the module adjusts excitation current to compensate for load changes, ensuring consistent power output.

-

-

Hydroelectric Power Plants:

-

Manages excitation for hydro turbines, optimizing water flow and turbine efficiency.

-

Example: A hydroelectric plant uses the GFD563A101 to implement a water-level-based control strategy, adjusting excitation current to maintain optimal turbine speed.

-

-

Nuclear Power Plants:

-

Regulates excitation for nuclear reactors, ensuring stable voltage output and compliance with safety standards.

-

Example: In a nuclear power plant, the module monitors reactor temperature and adjusts excitation current to prevent overheating.

-

-

Excitation System Upgrades:

-

Retrofits legacy excitation systems with modern control capabilities, extending the lifespan of existing equipment.

-

Example: A power plant upgrades its old analog excitation system with the GFD563A101, improving control precision and reducing maintenance costs.

-