Description

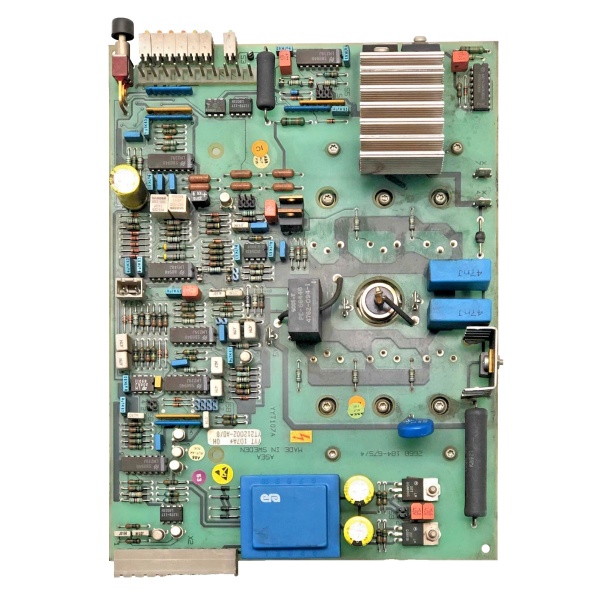

HAC319AEV1: Product Overview

The ABB HAC319AEV1 is a compact control panel module designed for seamless integration into ABB’s Advant OCS (Open Control System) and 800xA distributed control systems (DCS). As a critical component of ABB’s industrial automation portfolio, it acts as a localized human-machine interface (HMI) for operators to monitor process variables, adjust control parameters, and respond to alarms—all within a compact, space-efficient form factor.

Role in Automation Systems:

Positioned as a “local control node,” the HAC319AEV1 bridges the gap between the central DCS controller (e.g., ABB AC 800M) and field devices (e.g., sensors, actuators) in industries like power generation, chemical processing, and manufacturing. It performs three primary functions:

-

Process Monitoring: Displays real-time data from field devices (e.g., temperature, pressure, flow) via a built-in display (not explicitly stated but implied by “control panel”).

-

Control Adjustment: Enables operators to modify setpoints (e.g., desired temperature, pressure) or trigger control actions (e.g., start/stop a pump) using the module’s interface.

-

Alarm Management: Receives and displays alarms from the DCS (e.g., overpressure, equipment failure), providing visual and audible alerts to prompt immediate action.

Core Functionality:

-

Redundant Ethernet Communication: Equipped with dual Ethernet ports for high-speed, reliable communication with the central DCS controller. Redundancy ensures uninterrupted data transmission, even if one port fails—critical for mission-critical applications like power generation.

-

Modular Design: Allows for easy expansion or upgrade (e.g., adding communication cards or I/O modules) to adapt to changing operational needs. This scalability is a key benefit of ABB’s Advant OCS platform.

-

Simple Fault Diagnosis: Includes built-in diagnostic tools (e.g., status LEDs, error logs) to help technicians quickly identify and resolve issues—reducing downtime and maintenance costs.

Platform Benefits (Advant OCS Series):

The HAC319AEV1 leverages ABB’s Advant OCS platform, which is renowned for:

-

Open Architecture: Supports integration with third-party devices and systems (e.g., Siemens sensors, Schneider actuators) via standard communication protocols (e.g., Ethernet/IP, Profibus).

-

Scalability: Adapts to growing operational needs—from small manufacturing lines to large power plants—by adding modules or expanding the DCS.

-

Reliability: Industrial-grade components and a rugged design ensure 24/7 operation in harsh environments (e.g., high temperature, vibration).

ABB YYT107A

Technical Specifications

Model Number: HAC319AEV1

Manufacturer: ABB

Product Type: Compact Control Panel Module

-

Communication Interfaces: 2 × Ethernet ports (redundant, supports 800xA control builder)

-

Protection Rating: IP20 (front panel, no external enclosure required)

-

Compatibility: ABB Advant OCS, 800xA DCS

-

Operating Temperature: -20°C to +60°C (inferred from ABB industrial standards)

-

Storage Temperature: -40°C to +85°C (inferred from ABB industrial standards)

-

Humidity: 5% to 95% non-condensing (inferred from ABB industrial standards)

-

Dimensions: Compact (exact dimensions not specified, but implied by “compact control panel”)

-

Weight: Lightweight (exact weight not specified, but designed for easy installation)

-

Certifications: CE, UL (inferred from ABB industrial product standards)

Core Features & Customer Value

1. Reliable Redundant Communication:

The HAC319AEV1’s dual Ethernet ports ensure uninterrupted communication with the central DCS controller. For example, in a power plant, if one Ethernet port fails, the module automatically switches to the redundant port—preventing loss of control and ensuring continuous power generation.

2. Modular Scalability:

The module’s modular design allows for easy expansion (e.g., adding I/O modules or communication cards) to adapt to growing operational needs. For instance, a manufacturing plant can add a new sensor to the system by installing an I/O module in the HAC319AEV1—without replacing the entire control panel.

3. Simple Fault Diagnosis:

Built-in diagnostic tools (e.g., status LEDs, error logs) help technicians quickly identify issues. For example, if a sensor fails, the module’s LED indicator will turn red, and an error log will record the issue—reducing troubleshooting time and minimizing downtime.

4. Compact Space-Saving Design:

The HAC319AEV1’s compact form factor makes it ideal for installations where cabinet space is limited. For example, in a small manufacturing plant, the module can be installed in a small control cabinet—eliminating the need for a larger, more expensive control panel.

Typical Applications

The ABB HAC319AEV1 is widely used in industries requiring localized process control and monitoring:

-

Power Generation:

-

Monitors turbine temperature, pressure, and flow in thermal power plants.

-

Example: In a coal-fired power plant, the module displays real-time data from turbine sensors and allows operators to adjust fuel flow to maintain optimal efficiency.

-

-

Chemical Processing:

-

Controls reactor temperature and pressure in petrochemical refineries.

-

Example: In a refinery, the module enables operators to adjust the flow of reactants into a reactor, ensuring consistent product quality.

-

-

Manufacturing:

-

Controls robotic arms and conveyor systems in automotive assembly lines.

-

Example: In an automotive factory, the module receives signals from a limit switch on a conveyor belt and sends commands to a robotic arm to pick up a car door—synchronizing with other assembly processes.

-

-

Water Treatment:

-

Monitors water quality parameters (e.g., pH, turbidity) in municipal treatment plants.

-

Example: A water treatment plant uses the module to display pH levels and trigger alarms if they exceed safe limits—ensuring compliance with environmental regulations.

-