Description

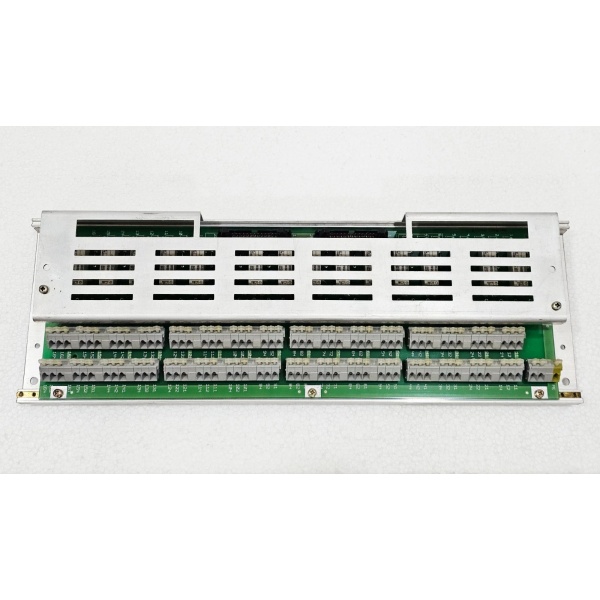

ABB HIEE300661R1 UPC090AE

-

Model Number: HIEE300661R1 UPC090AE -

Manufacturer: ABB -

Product Type: Universal Process Controller Module -

Processor: PowerPC 750FX, 600 MHz -

Memory: 512MB RAM, 4GB Flash (user program/log storage) -

Control Flexibility: Configurable for regulatory control, batch sequencing, data logging, or hybrid roles -

Communication Protocols: Profibus DP (up to 12 Mbps), Modbus TCP, Ethernet IP, IEC 61850 (optional) -

I/O Capacity: Up to 32,000 points (via S800 I/O modules, non-redundant) -

Operating Temperature: -40°C to +70°C -

Humidity Range: 5% to 95% non-condensing -

Power Supply: 24V DC (nominal, 18-32V DC range), redundant inputs supported -

Power Consumption: 12W (typical, single controller) -

Dimensions: 245mm x 135mm x 115mm (width x height x depth, fits UPC rack) -

Weight: 1.1kg -

Certifications: CE, UL, cULus, SIL 2 (IEC 61508, when integrated with safety logic)

ABB HIEE300661R1 UPC090AE