Description

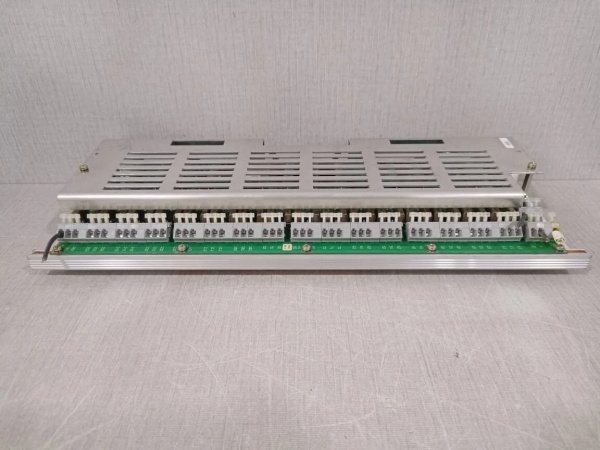

ABB HIEE300910R0001 UFC092BE01

-

Model Number: HIEE300910R0001 UFC092BE01 -

Manufacturer: ABB -

Product Type: Communication and Control Module Assembly -

System Compatibility: ABB Advant OCS / Advant Master DCS -

Communication Protocol: PROFIBUS DP/PA, HART (via companion module) -

Input Signal Types: 8x Analog (4-20mA), 16x Digital (24V DC) -

Output Signal Types: 4x Analog (4-20mA), 8x Digital (24V DC) -

Power Supply: 24 V DC (from I/O station backplane) -

Isolation: 500Vrms channel-to-backplane, 1500Vrms input-to-output -

Operating Temperature: 0°C to +55°C -

Storage Temperature: -40°C to +70°C -

Dimensions: 45mm (W) x 119mm (H) x 112mm (D) per module -

Weight: ~0.4 kg per module -

Certifications: CE, UL, ATEX Zone 2 (with approval)

ABB HIEE300910R0001 UFC092BE01