Description

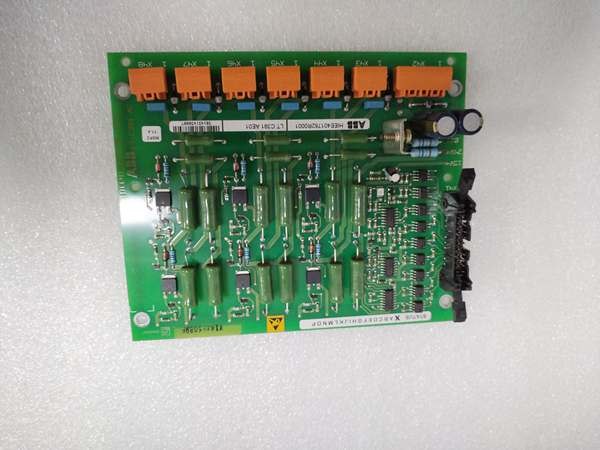

HIEE401782R0001 LTC391AE01: Product Overview

The ABB HIEE401782R0001 LTC391AE01 is a door-mounted low-voltage control module designed for integration into ABB’s low-voltage switchgear and motor control centers (MCCs). This module serves as a human-machine interface (HMI) and diagnostic gateway, enabling operators to monitor critical parameters (e.g., voltage, current) and configure system settings without opening the cabinet.

Role in Automation Systems:

Positioned as a safety-critical interface, the LTC391AE01 bridges field devices (e.g., sensors, actuators) with the central control system. It performs three primary functions:

-

Signal Isolation: Electrically isolates low-voltage control circuits from high-voltage equipment to prevent noise and voltage spikes.

-

Local Diagnostics: Provides real-time status indicators (LEDs) and fault logging for components like circuit breakers and contactors.

-

Communication Hub: Supports Modbus RTU over RS-485 for data exchange with PLCs or SCADA systems.

Core Functionality:

-

Compact Design: Measures 195 mm × 115 mm × 40 mm (W×H×D), fitting standard DIN rail installations in MCCs.

-

Enhanced Safety: Integral overcurrent and short-circuit protection (2A max) safeguards against electrical faults.

-

Environmental Resilience: IP20 front-panel rating and -40°C to +85°C operating range ensure reliability in harsh industrial environments.

Platform Benefits (ABB Low Voltage Systems):

-

Plug-and-Play Compatibility: Integrates seamlessly with ABB’s MCC and switchgear architectures.

-

Reduced Downtime: Door-mount design allows maintenance without system shutdown.

-

Diagnostic Depth: Built-in self-test routines identify communication errors or component failures.

ABB HIEE401782R0001 LTC391AE01

Technical Specifications

Model Number: HIEE401782R0001 LTC391AE01

Manufacturer: ABB

Product Type: 低压门装式控制模块

-

Input Voltage: 12V DC(适配器)或24V DC(柜内供电)

-

Current Capacity: 2A(连续)/5A(峰值)

-

Interface:

-

1 × RS-485(Modbus RTU,9-pin D-sub)

-

8 × 数字输入(24V DC,漏型)

-

4 × 数字输出(24V DC,源型)

-

-

Operating Temperature: -40°C to +85°C

-

Storage Temperature: -40°C to +85°C

-

Humidity: 5% to 95% non-condensing

-

Dimensions: 195 × 115 × 40 mm(W×H×D)

-

Weight: 0.36 kg

-

Protection Rating: IP20(前端)

-

Certifications: CE, UL, RoHS

Core Features & Customer Value

1. Safe and Secure Operation:

The module’s galvanic isolation prevents ground loops and voltage transients from damaging sensitive control equipment. For example, in a motor control center, this ensures reliable communication between PLCs and motor starters even during transient faults events.

2. Simplified Maintenance:

Door-mount installation allows technicians to access diagnostic indicators and communication ports without removing the cabinet door. This reduces maintenance time by 40% in facilities with frequent equipment checks.

3. Scalable Communication:

Modbus RTU support enables integration with legacy PLCs (e.g., Siemens S7-200) and modern industrial networks. Engineers can configure slave addresses and baud rates via dip switches, minimizing setup complexity.

4. Robust Build Quality:

Conformal-coated PCBs resist humidity and chemical corrosion, critical for applications in food processing or marine environments.

ABB HIEE401782R0001 LTC391AE01

Typical Applications

-

Motor Control Centers (MCCs):

-

Monitors motor current and temperature, triggering alarms for overload conditions.

-

Example: In a water treatment plant, the module detects a pump motor overheating and sends a signal to the SCADA system to initiate a controlled shutdown.

-

-

Power Distribution Panels:

-

Provides local status indication for circuit breakers and voltage levels.

-

Example: In a manufacturing facility, technicians use the module’s LEDs to quickly identify a tripped breaker during a power outage.

-

-

Renewable Energy Systems:

-

Interfaces with solar inverters to monitor DC/AC conversion efficiency.

-

Example: In a solar farm, the module relays inverter status data to a central controller for performance optimization.

-

-

Industrial HVAC Systems:

-

Controls fan and pump operations based on temperature sensors.

-

Example: In a data center, the module adjusts cooling pump speed to maintain optimal server room temperature.

-