Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | HVC-02B |

| Manufacturer | ABB |

| Product category | High-voltage contactor (HVAC and industrial control) |

| Rated voltage | 12kV AC (maximum 15kV) |

| Rated current | 630A (continuous), 3150A (inrush) |

| Breaking capacity | 25kA (symmetrical) |

| Operating mechanism | Electromagnetic (spring-assisted) |

| Control voltage | 220V DC / 110V DC (selectable) |

| Coil power consumption | 50W (pull-in), 10W (holding) |

| Insulation level | LI75kV, SI35kV |

| Operating temperature | -30°C to 70°C |

| Protection rating | IP54 (enclosed version) |

| Dimensions | 450mm × 300mm × 280mm |

| Weight | 25kg |

| Certifications | IEC 62271-203, CE, CCC |

| Mounting type | Flange or panel mount |

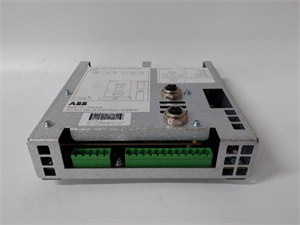

ABB HVC-02B

Product introduction

The ABB HVC-02B is a robust high-voltage contactor designed for reliable switching and control of high-voltage circuits in industrial and infrastructure applications. As a key component in power distribution systems, this contactor excels at managing the flow of electrical power in medium-voltage networks, providing safe and efficient operation in scenarios ranging from renewable energy installations to industrial plants.

Featuring a compact design and high-performance electromagnetic operating mechanism, the ABB HVC-02B is engineered to handle 12kV AC systems with a rated current of 630A, making it suitable for both continuous operation and handling inrush currents up to 3150A. Its robust construction ensures durability in harsh environments, while its advanced insulation system guarantees safe operation even under extreme voltage conditions.

Within electrical systems, the ABB HVC-02B serves as a critical switching device, controlling the connection and disconnection of high-voltage loads such as transformers, motors, and capacitor banks. Its fast response time (≤50ms) ensures quick fault isolation, minimizing downtime and enhancing system reliability. Whether deployed in solar power plants, wind farms, or industrial facilities, this contactor delivers consistent performance in demanding high-voltage applications.

Core advantages and technical highlights

High current handling capability: The ABB HVC-02B supports a continuous current of 630A and inrush currents up to 3150A, making it ideal for applications with high starting currents, such as large motors or transformer banks. This capability ensures reliable operation during peak load conditions, preventing contact overheating and extending the device’s lifespan.

Robust insulation system: With an insulation level of LI75kV (lightning impulse) and SI35kV (switching impulse), the ABB HVC-02B provides superior protection against voltage surges and transients. This is particularly critical in outdoor installations or areas with frequent lightning activity, where voltage spikes can damage sensitive equipment.

Efficient operating mechanism: The electromagnetic operating mechanism with spring assistance reduces coil power consumption, requiring only 50W during pull-in and 10W for holding. This energy efficiency lowers operational costs and reduces heat generation, contributing to a longer service life for both the contactor and associated control systems.

Wide temperature range: Designed to operate from -30°C to 70°C, the ABB HVC-02B adapts to extreme climatic conditions, making it suitable for outdoor installations in cold regions or hot industrial environments. Its ability to function reliably across this range eliminates the need for climate-controlled enclosures, reducing installation costs.

Quick response time: The contactor’s fast switching time (≤50ms) ensures rapid fault isolation, which is crucial for protecting downstream equipment from damage during short circuits or other electrical faults. This quick response also minimizes power interruptions, improving overall system availability.

Typical application scenarios

In solar power plants, the ABB HVC-02B is used to control the connection of solar inverter outputs to the medium-voltage grid. It switches high-voltage DC/AC converters, ensuring safe disconnection during maintenance or fault conditions. Its high inrush current handling capability accommodates the surge currents generated when inverters start up, while its robust insulation protects against voltage fluctuations common in renewable energy systems.

Within industrial facilities, the ABB HVC-02B controls high-voltage motors used in pumps, compressors, and fans. It provides reliable on/off switching and overload protection, ensuring smooth operation of critical machinery. Its wide temperature range allows installation in unheated or poorly ventilated areas, such as underground pump rooms or foundries.

In electrical distribution substations, the ABB HVC-02B manages capacitor banks used for power factor correction. It switches the banks in and out of the circuit based on load conditions, optimizing energy efficiency. Its fast response time ensures rapid adjustment to changing load demands, maintaining stable voltage levels across the network.

ABB HVC-02B

Related model recommendations

ABB HVC-03B: A higher-capacity variant of the ABB HVC-02B with a rated current of 1250A, suitable for larger industrial applications.

ABB REL650: A protection relay that works with the ABB HVC-02B to provide overcurrent, earth fault, and thermal protection.

ABB T2N: A series of medium-voltage circuit breakers that complement the ABB HVC-02B in high-voltage distribution systems.

ABB AC500 PLC: A programmable logic controller that controls the ABB HVC-02B via its electromagnetic operating mechanism.

ABB CM-MPS: A DC power supply module that provides stable control voltage to the ABB HVC-02B‘s operating coil.

ABB 800xA DCS: A distributed control system that monitors and controls the ABB HVC-02B in large-scale industrial plants.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the ABB HVC-02B, ensure the mounting surface is flat, level, and capable of supporting the contactor’s weight (25kg). Verify the high-voltage circuit matches the contactor’s rated voltage (12kV) and current (630A). Required tools include a torque wrench (50-100 Nm), insulated screwdrivers, and a multimeter. Use copper busbars of appropriate size (minimum 120mm²) for high-voltage connections, ensuring proper clearance (≥300mm) between phases.

Commissioning steps: After installation, perform insulation resistance tests using a 2500V megohmmeter, ensuring values exceed 1000MΩ. Check the control voltage (220V DC or 110V DC) and verify the operating mechanism functions correctly by performing 10 no-load switching operations. Measure contact resistance using a micro-ohmmeter, ensuring values are ≤50μΩ. Calibrate the auxiliary switches to ensure they operate in sync with the main contacts.

Maintenance suggestions: Inspect the ABB HVC-02B annually for signs of arcing, corrosion, or loose connections. Clean the contacts with a wire brush if necessary, and check for wear—replace contacts if their thickness is less than 50% of the original. Lubricate the operating mechanism’s moving parts with high-temperature grease. Test the insulation resistance quarterly and the contact resistance semi-annually. Replace the operating coil every 10 years or if it shows signs of overheating.

Service and guarantee commitment

The ABB HVC-02B comes with a 5-year warranty from the date of commissioning, covering manufacturing defects and ensuring compliance with published performance specifications. ABB guarantees replacement of faulty contactors within 72 hours for critical applications, minimizing downtime in high-voltage systems.

Technical support includes access to ABB’s global team of high-voltage specialists, available for assistance with installation, commissioning, and troubleshooting. Online resources include detailed installation manuals, maintenance guides, and compatibility charts. Customers can opt for extended service contracts offering annual preventive maintenance, on-site testing, and priority technical support, ensuring the ABB HVC-02B delivers reliable performance throughout its 20-year design lifespan.