Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | IDPG 940128102 |

| Manufacturer | ABB |

| Product category | Industrial pressure transmitter (for process control) |

| Measurement range | 0-10 bar (gauge pressure) |

| Accuracy | ±0.1% of full scale |

| Output signal | 4-20 mA DC, 2-wire |

| Power supply | 12-30 V DC |

| Operating temperature | -40°C to 85°C |

| Process temperature | -20°C to 100°C |

| Overpressure rating | 5x full scale (50 bar) |

| Protection rating | IP67 (transmitter body), IP65 (electrical connection) |

| Process connection | G1/2 male thread |

| Electrical connection | M12 circular connector |

| Response time | ≤10 ms |

| Long-term stability | ±0.1% of full scale per year |

| Weight | 0.5 kg |

| Certifications | IEC 61508, ATEX, IECEx, CE, UL |

| Material | 316L stainless steel (wetted parts), aluminum alloy (housing) |

| Mounting type | Direct process mounting or bracket mounting |

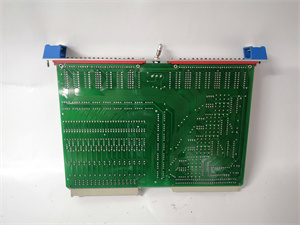

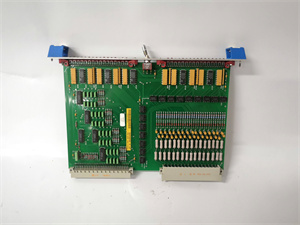

ABB IDPG 940128102

Product introduction

The ABB IDPG 940128102 is a high-precision industrial pressure transmitter designed to deliver accurate and reliable pressure measurements in demanding process control environments. As a key component in ABB’s portfolio of process instrumentation, this transmitter converts mechanical pressure into a standardized 4-20 mA electrical signal, enabling seamless integration with PLCs, DCS systems, and other automation equipment.

Engineered for gauge pressure applications with a measurement range of 0-10 bar, the ABB IDPG 940128102 is ideal for monitoring and controlling pressure in industrial processes such as fluid handling, HVAC systems, and manufacturing lines. Its 316L stainless steel wetted parts ensure compatibility with a wide range of media, including water, oils, and mild chemicals, while the rugged aluminum alloy housing provides durability in harsh operating conditions.

With a combination of high accuracy (±0.1% of full scale) and fast response time (≤10 ms), the transmitter delivers real-time pressure data critical for maintaining process stability and efficiency. Its IP67 protection rating allows for installation in wet or dusty environments, while hazardous area certifications (ATEX, IECEx) enable deployment in potentially explosive atmospheres—making it a versatile solution across diverse industrial sectors.

Core advantages and technical highlights

Superior measurement accuracy

The ABB IDPG 940128102 achieves ±0.1% full scale accuracy, ensuring precise pressure monitoring even in dynamic processes. This level of precision is crucial for applications such as pharmaceutical manufacturing, where pressure variations of less than 0.01 bar can affect product quality. The transmitter’s advanced sensor technology minimizes drift, maintaining accuracy over extended periods without frequent recalibration.

Robust environmental performance

Designed to operate in temperatures ranging from -40°C to 85°C, the transmitter thrives in extreme conditions—from frozen food processing facilities to hot industrial boilers. Its IP67 rating protects against water immersion up to 1 meter for 30 minutes, making it suitable for outdoor installations or washdown environments (e.g., food and beverage plants). The 316L stainless steel construction resists corrosion, ensuring longevity in chemical processing applications.

Fast response and reliability

With a response time of ≤10 ms, the ABB IDPG 940128102 quickly detects pressure fluctuations, enabling rapid corrective actions in critical processes. For example, in a water treatment plant, it can signal a sudden pressure drop in a pipeline within 10 ms, triggering a valve closure to prevent equipment damage. The transmitter’s overpressure tolerance (5x full scale) adds a layer of protection against unexpected pressure spikes, common in pumping systems.

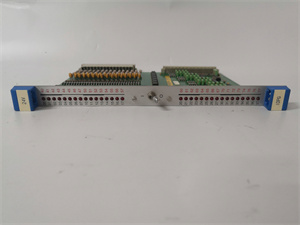

Easy integration and installation

The standardized 4-20 mA, 2-wire output ensures compatibility with most industrial control systems, including ABB’s AC 800M DCS and third-party PLCs. The M12 electrical connector and G1/2 process connection simplify installation, reducing downtime during setup. The transmitter supports both direct mounting (via process connection) and bracket mounting, offering flexibility in tight spaces or remote locations.

Hazardous area certification

ATEX and IECEx certifications allow the ABB IDPG 940128102 to be deployed in Zone 2 (gas) and Zone 22 (dust) hazardous areas, such as chemical storage facilities or grain processing plants. This eliminates the need for expensive explosion-proof enclosures, reducing installation costs while ensuring compliance with safety regulations.

Typical application scenarios

Water and wastewater treatment

In a municipal water distribution system, the ABB IDPG 940128102 monitors pipeline pressure (0-10 bar) to ensure consistent water flow to residential and industrial areas. Its fast response time detects pressure drops caused by leaks, alerting operators via the SCADA system. The transmitter’s corrosion-resistant design withstands chlorinated water, ensuring reliable performance in disinfection processes.

Food and beverage processing

In a beer brewing facility, the transmitter monitors pressure in fermentation tanks (0-5 bar), where precise pressure control is critical for carbonation levels. Its stainless steel wetted parts meet FDA standards for food contact, while the IP67 rating allows for thorough cleaning with high-pressure hoses. The 4-20 mA output integrates with the brewery’s PLC, automatically adjusting pressure to maintain consistent product quality.

HVAC systems

In large commercial buildings, the ABB IDPG 940128102 regulates pressure in heating and cooling loops (0-8 bar). It provides real-time data to the building management system, which adjusts pump speeds to optimize energy efficiency. The transmitter’s wide operating temperature range ensures accuracy in both chiller rooms (-10°C) and boiler rooms (60°C).

Chemical processing

In a batch reactor system, the transmitter monitors gauge pressure during chemical reactions (0-10 bar). Its ATEX certification allows installation in areas with flammable vapors, while the 316L stainless steel construction resists corrosion from aggressive chemicals. The fast response time ensures operators are alerted immediately to pressure deviations, preventing hazardous overpressure situations.

ABB IDPG 940128102

Related model recommendations

ABB IDPG 940128103: A variant with a 0-20 bar measurement range, suitable for high-pressure applications like hydraulic systems.

ABB AI895 3BSC690089R1: An analog input module that pairs with the ABB IDPG 940128102 to process 4-20 mA signals in AC 800M systems.

ABB TB857 3BSE013269R1: A surge-protected terminal block that enhances noise immunity for the transmitter’s signal in high-EMI environments.

ABB 800xA DCS: A distributed control system that visualizes pressure data from the ABB IDPG 940128102, enabling advanced process control.

ABB XO08R2 1SBP260109R1001: A digital output module that triggers alarms or valves based on pressure thresholds detected by the ABB IDPG 940128102.

ABB Calibration Kit 3BHT300063R1: A tool for verifying and calibrating the ABB IDPG 940128102 to maintain accuracy.

Installation, commissioning and maintenance instructions

Installation preparation

Verify the process pressure range (0-10 bar) matches application requirements. Ensure the process medium is compatible with 316L stainless steel.

Select a mounting location with minimal vibration and away from direct heat sources. For hazardous areas, confirm compliance with Zone 2/22 classification.

Prepare tools: torque wrench (for process connection), wire strippers, and a multimeter. Use shielded twisted-pair cable (0.5 mm²) for electrical connections, with the shield grounded at the control system end.

Check that the power supply (12-30 V DC) is properly fused (0.5 A) and isolated from noise sources.

Installation steps

Mount the ABB IDPG 940128102 via the G1/2 process connection, ensuring a tight seal with a compatible gasket (PTFE recommended for chemical compatibility). Torque to 25-30 Nm to prevent leaks.

Connect the M12 electrical connector to the 2-wire 4-20 mA loop, ensuring correct polarity (positive to +V, negative to -V).

Power on the system and allow the transmitter to stabilize for 15 minutes before calibration.

Secure the cable to prevent strain on the M12 connector, using cable ties or a bracket.

Commissioning steps

Apply a known pressure (e.g., 0 bar and 10 bar) using a precision pressure calibrator. Verify the output signal corresponds to 4 mA (0 bar) and 20 mA (10 bar) within ±0.1% tolerance.

Check linearity by testing intermediate points (e.g., 5 bar should output 12 mA). Adjust using the transmitter’s calibration port if necessary (refer to ABB’s calibration guide).

Validate response time by rapidly changing pressure (e.g., from 2 bar to 8 bar) and confirming the output stabilizes within 10 ms.

Test communication with the control system (e.g., AC 800M PLC) to ensure pressure data is displayed correctly. Configure alarms for high/low pressure thresholds (e.g., 9 bar and 1 bar).

Maintenance suggestions

Inspect the ABB IDPG 940128102 quarterly for signs of leakage at the process connection or damage to the housing. Clean the sensor port with a soft brush if clogged with debris.

Calibrate annually using a certified pressure calibrator to maintain ±0.1% accuracy. Record calibration data for audit trails (critical for FDA-regulated industries).

Check electrical connections semi-annually for corrosion or looseness, especially in humid environments. Replace the M12 connector if pins show signs of wear.

In applications with viscous media (e.g., oils), flush the sensor port periodically to prevent buildup that could affect accuracy.

Replace the transmitter if it fails calibration (error >±0.2% full scale) or if the housing is damaged (compromising IP67 protection).

Service and guarantee commitment

The ABB IDPG 940128102 comes with a 5-year warranty from the date of installation, covering manufacturing defects and ensuring compliance with published accuracy specifications. ABB guarantees that any transmitter failing to meet performance standards during this period will be replaced within 72 hours, minimizing downtime in process control systems.

Technical support includes access to ABB’s global team of process instrumentation specialists, available 24/7 for assistance with installation, calibration, and troubleshooting. Online resources include detailed wiring diagrams, calibration procedures, and compatibility guides for integration with ABB control systems. Customers can opt for extended service contracts offering annual preventive maintenance, on-site calibration, and priority technical support, ensuring the transmitter delivers reliable pressure measurements throughout its 10-year design lifespan.