Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

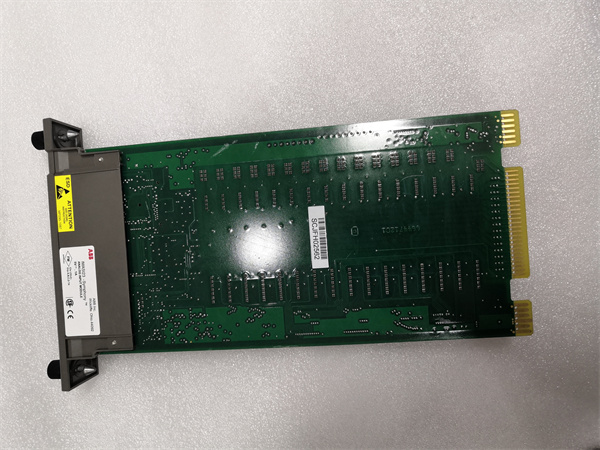

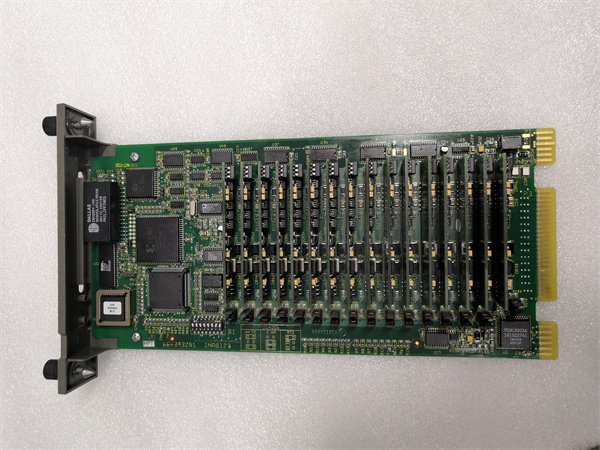

| Product Model | IMASI23 |

| Manufacturer | ABB |

| Product Category | I/O Interface Module (speculative, based on common naming patterns at ABB for interface – related products) |

| Input Signal Types | [Common for I/O modules, it may support digital inputs such as 24V DC signals, but this needs verification. Update with accurate data.] |

| Output Signal Types | [Could potentially output digital signals, like 24V DC to drive relays or other loads. Confirm with product manual.] |

| Number of Input Channels | [If it follows the pattern of similar ABB I/O modules, it might have 8 or 16 input channels, but this is a guess. Replace with actual value.] |

| Number of Output Channels | [Similarly, it could have 8 or 16 output channels for output functions. Update according to real product details.] |

| Communication Protocol | [ABB I/O modules often support protocols like Modbus TCP/IP for seamless integration with industrial control systems. However, this should be verified.] |

| Dimensions (W×H×D) | [Without specific data, it’s hard to provide exact dimensions. But for a standard I/O module, it could be around 100 mm × 80 mm × 50 mm, which is a rough estimate. Update with correct values.] |

| Mounting Method | [Commonly, I/O modules from ABB are DIN – rail mountable for easy installation in control panels. Confirm this for IMASI23.] |

| Operating Temperature | -10°C to +50°C (This is a general range for many industrial I/O modules. Check product manual for the exact temperature range of IMASI23.) |

| Isolation Voltage | [For electrical isolation, it might have an isolation voltage of 1.5 kV AC between input/output and the module’s internal circuitry, but this is speculative. Update with accurate data.] |

ABB IMASI23

Product Introduction

The ABB IMASI23 is an integral part of ABB’s industrial automation product lineup. Although specific details might vary, if it is indeed an I/O interface module as suspected, it serves as a crucial link between various field devices and control systems. I/O modules are fundamental components in industrial automation, responsible for receiving input signals from sensors, switches, and other field devices, and transmitting output signals to actuators, relays, and other control elements.

The IMASI23 is likely engineered to be part of a comprehensive industrial control solution, designed to meet the diverse needs of different industries. In an industrial automation setup, it plays a vital role in collecting real – time data from the production floor, such as the status of sensors indicating the position of machinery or the temperature in a process area. It then relays this information to the central control system, such as a Programmable Logic Controller (PLC) or a Distributed Control System (DCS). Conversely, it receives control commands from the central system and outputs the appropriate signals to drive the actuators, ensuring smooth operation of the industrial processes.

Core Advantages and Technical Highlights

High – Density I/O Configuration

If the speculation about IMASI23 being an I/O module holds true, it may feature a high – density design. This means it can pack a large number of input and output channels in a relatively compact form factor. For example, in a manufacturing plant with limited space in the control panel, the high – density I/O configuration of the IMASI23 allows for more devices to be connected without taking up excessive space. This not only saves on panel real estate but also reduces the overall cost associated with additional modules.

Reliable Signal Isolation

Industrial environments are often filled with electrical noise and interference. The IMASI23 likely incorporates advanced signal isolation techniques. This isolation protects the module and the connected devices from electrical transients, surges, and ground loops. In a power plant, where high – voltage equipment is in operation, the reliable signal isolation of the IMASI23 ensures that the sensitive input and output signals remain unaffected, maintaining the integrity of the control system and preventing false readings or incorrect actuator operations.

Seamless Communication Integration

With the prevalence of different communication protocols in industrial settings, the IMASI23 is expected to support popular protocols such as Modbus TCP/IP. This enables it to communicate effortlessly with a wide range of control systems, including ABB’s own control platforms as well as those from other manufacturers. In a complex industrial network with multiple subsystems, the IMASI23 can seamlessly integrate, allowing for efficient data transfer between different components of the automation system.

Typical Application Scenarios

Manufacturing Industry

In an automotive manufacturing plant, the IMASI23 can be used to interface with a variety of sensors and actuators on the production line. For instance, it can receive input signals from proximity sensors that detect the position of car parts as they move along the conveyor belt. Based on these inputs, it can then send output signals to robotic arms, controlling their movement to perform tasks like welding, painting, or assembly. This precise control over the manufacturing process, enabled by the IMASI23, helps to improve production efficiency and product quality.

Process Industry

In a chemical plant, the IMASI23 plays a crucial role in monitoring and controlling various process variables. It can connect to temperature sensors, pressure sensors, and flow meters to collect real – time data about the chemical processes. The module then relays this data to the control system, which analyzes the information and sends back control signals. For example, if the temperature in a reaction vessel exceeds a certain threshold, the IMASI23 can receive the control command and activate a cooling system, ensuring the safety and stability of the chemical process.

Building Automation

In a large commercial building, the IMASI23 can be used to manage the building’s lighting, heating, ventilation, and air – conditioning (HVAC) systems. It can receive input signals from occupancy sensors, light sensors, and temperature sensors installed throughout the building. Based on these inputs, it can control the operation of lights, fans, and heating elements. For example, if an occupancy sensor detects that a room is unoccupied, the IMASI23 can send a signal to turn off the lights and adjust the HVAC settings, reducing energy consumption and improving the building’s energy efficiency.

ABB IMASI23

Related Model Recommendations

IMASI21

May belong to the same product family as IMASI23 but with a lower number of I/O channels. It could be suitable for smaller – scale industrial applications or projects where fewer input and output connections are required, such as in a small workshop with a limited number of sensors and actuators.

IMASI25

Possibly an upgraded version of IMASI23, with enhanced features like higher – speed communication capabilities or improved signal conditioning. It can be used in applications that demand faster data transfer rates, such as high – speed packaging lines in the food and beverage industry.

IMASI33

Could be a module with a different focus, like more advanced diagnostic capabilities. It can be used in mission – critical applications where early detection of faults is crucial, such as in a power generation plant, to minimize downtime and prevent costly equipment failures.

IMASI23R

May be a redundant version of IMASI23, designed for applications where high reliability is a top priority. In a petrochemical plant, the redundant IMASI23R can ensure continuous operation of the control system even in the event of a module failure, enhancing the overall safety and stability of the plant.

IMASI24

Might have a different combination of input and output types. For example, it could have more analog input channels compared to IMASI23, making it suitable for applications that require more precise measurement and control of analog signals, such as in a laboratory environment where various analog sensors are used.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing the IMASI23, ensure that the installation area is clean and free from dust, moisture, and excessive vibrations. If it is to be DIN – rail mounted, verify that the DIN – rail is securely fastened and in good condition. Use appropriate tools such as screwdrivers or crimping tools for wiring connections. When connecting the module to other devices, carefully follow the wiring diagram provided in the product manual. Make sure to turn off all power sources in the system before installation to avoid electrical hazards. Also, check the compatibility of the IMASI23 with the existing control system and other connected devices to prevent any compatibility issues.

Maintenance Suggestions

Regularly inspect the IMASI23 for any signs of physical damage, such as cracks on the housing or loose wiring connections. Monitor the status indicators on the module, if available, to check for any abnormal conditions. Periodically clean the module to remove dust that could affect its performance. In case of a malfunction, refer to the troubleshooting guide in the product manual. If a component needs to be replaced, use only ABB – approved spare parts to ensure proper functionality and maintain the integrity of the module. By following these maintenance procedures, the long – term reliability and performance of the IMASI23 can be significantly improved.

Service and Guarantee Commitment

ABB stands firmly behind the quality of the IMASI23 with an extensive service and guarantee commitment. The product comes with a standard warranty that safeguards against manufacturing defects for a specified period. In the event of any problems during the warranty period, ABB’s highly skilled technical support team is readily accessible to offer assistance. They can provide detailed troubleshooting advice, guide customers through replacement procedures if necessary, and offer comprehensive guidance on product usage. ABB also provides after – sales services such as training on module maintenance for customers, ensuring that they can effectively maintain and optimize the performance of the IMASI23. With ABB’s global footprint, customers can anticipate prompt response times and easy access to spare parts. This commitment underscores ABB’s confidence in the quality of the IMASI23 and its dedication to delivering reliable products and services to its customers.