Description

Detailed parameter table

| Parameter name | Parameter value |

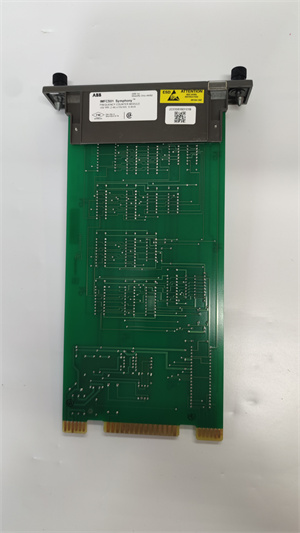

| Product model | IMFCS01 |

| Manufacturer | ABB |

| Product category | Fieldbus communication interface module (S800 I/O system) |

| Supported protocols | FOUNDATION Fieldbus H1 |

| Data transfer rate | 31.25 kbps |

| Number of segments | 1 segment with up to 32 field devices |

| Bus voltage | 9-32 V DC (powered via fieldbus) |

| Isolation | 2.5 kV AC (bus to system) |

| Operating temperature | -40°C to +70°C |

| Dimensions (W×H×D) | 22 mm × 105 mm × 115 mm |

| Installation method | DIN rail mounting via TB820V2 terminal base |

| Diagnostic features | Bus status monitoring, device fault detection, LED indicators |

| Compliance | IEC 61158-2, FOUNDATION Fieldbus Certified, CE, UL 508 |

| Compatible systems | ABB AC800M controller, S800 I/O modules, FOUNDATION Fieldbus devices (e.g., transmitters, valves) |

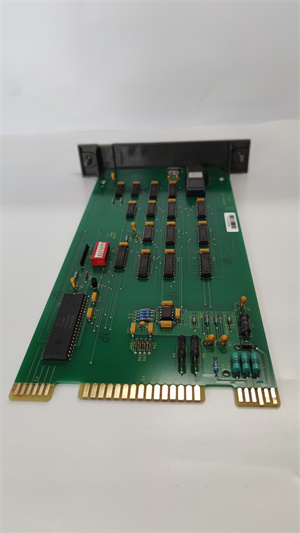

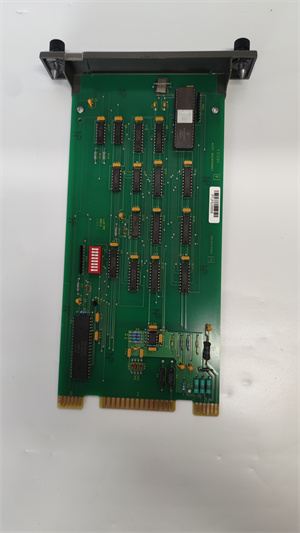

ABB IMFCS01

Product introduction

The IMFCS01 is a specialized FOUNDATION Fieldbus H1 communication interface module from ABB, designed to connect the S800 I/O system and AC800M controller to FOUNDATION Fieldbus networks. As a critical link between the control layer and intelligent field devices, IMFCS01 enables seamless data exchange with smart transmitters, valves, and analyzers, supporting both process control and device management functions.

By integrating IMFCS01 into industrial automation systems, users gain access to advanced features like predictive maintenance data, device configuration, and real-time process variables from fieldbus devices. Its compact design and rugged construction make it suitable for harsh industrial environments, from chemical plants to oil refineries. Whether deployed in new installations or retrofitted into existing FOUNDATION Fieldbus networks, IMFCS01 ensures reliable communication, enhancing operational efficiency and reducing lifecycle costs.

Core advantages and technical highlights

Advanced fieldbus integration

IMFCS01 fully supports FOUNDATION Fieldbus H1 protocol, enabling bidirectional communication with intelligent field devices. This allows the module to not only collect process data (e.g., pressure, temperature) but also access device diagnostics, calibration data, and health status. In a chemical processing plant, this capability lets maintenance teams remotely check the condition of a flow transmitter connected to IMFCS01, scheduling calibration during planned shutdowns rather than reacting to failures.

High device capacity

With support for up to 32 field devices per segment, IMFCS01 reduces the need for multiple communication modules in large-scale installations. In a water treatment plant with distributed monitoring points, a single IMFCS01 can manage all FOUNDATION Fieldbus devices across the facility, including pH sensors, level transmitters, and chemical dosing valves—simplifying network architecture and lowering installation costs.

Robust industrial design

Operating reliably in temperatures from -40°C to +70°C, IMFCS01 thrives in extreme environments. Its 2.5 kV isolation protects against electrical noise and ground loops, ensuring stable communication in areas with heavy machinery or high-voltage equipment. In an offshore oil platform, where humidity and vibration are constant challenges, IMFCS01 maintains consistent performance, ensuring critical process data reaches the AC800M controller without interruption.

Typical application scenarios

In a large-scale pharmaceutical manufacturing facility, IMFCS01 serves as the communication hub for a FOUNDATION Fieldbus network in a batch processing area:

- Connects to 18 smart devices, including temperature transmitters, pressure sensors, and control valves

- Transmits real-time process data to the AC800M controller for precise batch control

- Enables remote configuration of device parameters (e.g., sensor ranges, valve response times) via ABB’s Control Builder M software

- Provides diagnostic alerts for issues like sensor drift or valve stiction, allowing proactive maintenance

In a natural gas processing plant, IMFCS01 integrates with FOUNDATION Fieldbus devices in the amine treating unit:

- Monitors 24 smart transmitters measuring gas composition, pressure, and temperature

- Facilitates remote tuning of control valves to optimize gas purification efficiency

- Supports partial stroke testing of emergency shutdown valves, ensuring safety compliance without process interruption

The module’s rugged design withstands the plant’s harsh conditions, including exposure to corrosive gases and temperature fluctuations.

ABB IMFCS01

Related model recommendations

- IMFBF01: Redundant FOUNDATION Fieldbus interface module that pairs with IMFCS01for high-availability systems.

- AC800M with PM864: Controller that processes data from IMFCS01and executes control strategies.

- TB820V2: Terminal base required for mounting IMFCS01, providing secure connections for fieldbus wiring.

- SPASO11: Safety digital output module that works alongside IMFCS01in systems requiring both process control and safety functions.

- CI840A: Profibus communication module that complements IMFCS01in mixed-protocol environments.

- 3500 Series: ABB smart transmitters designed for use with IMFCS01in FOUNDATION Fieldbus networks.

- VALVEBASE: Intelligent valve positioner that communicates with IMFCS01for precise flow control.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing IMFCS01, ensure the S800 I/O rack is powered off and the installation area is clean and dry. Mount the TB820V2 terminal base on a 35 mm DIN rail, leaving 30 mm clearance for airflow. Connect the FOUNDATION Fieldbus H1 cable (twisted-pair, shielded) to the terminal base, ensuring proper termination with a 100Ω resistor at the end of the segment. Ground the cable shield at both ends to minimize electrical noise. Power the module via the S800 I/O backplane, verifying 24 V DC supply within ±10% tolerance.

Maintenance suggestions

Daily checks of IMFCS01 involve verifying green LEDs for power and bus activity; flashing or red LEDs indicate communication issues. Use ABB’s Field Device Manager software monthly to run diagnostic tests on connected field devices via IMFCS01, checking for signal integrity and device health. Inspect fieldbus connections quarterly for tightness and corrosion, tightening terminals to 0.5 Nm if needed. If communication failures persist, replace IMFCS01 with an ABB-approved spare, reconfiguring device addresses to match the original setup before returning to service.

Service and guarantee commitment

IMFCS01 is backed by a 3-year warranty, covering defects in materials and workmanship under normal operating conditions. ABB’s fieldbus specialists provide on-site commissioning support, including network configuration, device integration, and protocol verification to ensure compliance with FOUNDATION Fieldbus standards.

Customers receive access to detailed installation guides, network planning documents, and application notes specific to IMFCS01. ABB’s global technical support team offers 24/7 assistance for troubleshooting communication issues, with response times guaranteed under service level agreements. For critical applications, ABB provides spare module stocking options to minimize downtime, ensuring continuous operation of FOUNDATION Fieldbus networks.