Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | IMRIO02 |

| Manufacturer | ABB |

| Product Category | Modular remote I/O module (for distributed automation systems) |

| I/O Configuration | 16 digital inputs (24 V DC), 8 digital outputs (24 V DC, 2 A per channel) |

| Communication Protocols | Modbus TCP/IP, PROFINET, EtherNet/IP (selectable via configuration) |

| Data Transfer Rate | 100 Mbps (full-duplex Ethernet) |

| Operating Voltage | 24 V DC ±15% |

| Power Consumption | ≤ 10 W |

| Operating Temperature | -30°C to +70°C |

| Dimensions (W×H×D) | 150 mm × 220 mm × 90 mm |

| Mounting Method | DIN rail mounting (35 mm standard) with locking clips |

| Protection Rating | IP65 (when used with optional protective housing) |

| Expansion Capability | Supports up to 4 I/O expansion modules (e.g., IMRIO-EX16) |

| Response Time | ≤ 2 ms (input signal to controller) |

| Isolation | 2 kV AC (channel-to-bus, channel-to-channel) |

| Certification | CE, UL 508, IEC 61131-2, ATEX Zone 2 |

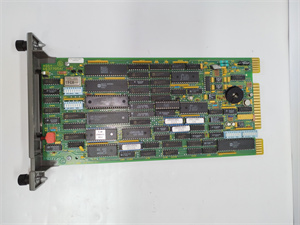

ABB IMRIO02

Product Introduction

The ABB IMRIO02 is a compact, modular remote I/O module designed to extend control capabilities in distributed industrial automation systems. As a key component in ABB’s distributed I/O portfolio, it serves as a bridge between field devices (sensors, switches, actuators) and central controllers (PLCs, DCS), enabling real-time data exchange without the need for costly, long-distance wiring.

Featuring 16 digital inputs and 8 digital outputs, the IMRIO02 handles diverse field signals, from proximity sensor data to relay control commands. Its multi-protocol support (Modbus TCP/IP, PROFINET, EtherNet/IP) ensures seamless integration with ABB’s AC500 PLCs and third-party control systems, making it ideal for retrofits or new installations. The module’s rugged design—including wide temperature tolerance and IP65 protection with an optional housing—allows reliable operation in harsh environments, from freezing warehouses to dusty manufacturing floors.

Core Advantages and Technical Highlights

Multi-protocol flexibility

The IMRIO02 supports three major industrial Ethernet protocols, configurable via software. In a mixed-vendor factory, this allows the module to communicate with an ABB AC500 PLC via Modbus TCP/IP while connecting to a third-party HMI via PROFINET—eliminating the need for protocol converters. This flexibility reduces integration time by up to 30% compared to single-protocol remote I/O modules.

Distributed efficiency

By placing I/O closer to field devices, the IMRIO02 minimizes wiring costs and signal degradation. In a large automotive plant with production lines spread over 500 meters, it reduces cable usage by 60% versus centralized I/O setups. Its ≤2 ms response time ensures critical signals (e.g., emergency stop commands) reach the controller without delay, enhancing process safety.

Expandable design

The IMRIO02 supports up to 4 expansion modules, scaling I/O capacity to match application needs. A logistics warehouse, for example, can start with basic digital I/O via IMRIO02 and later add IMRIO-EX16 analog modules to monitor conveyor motor temperatures—all without replacing the base unit, reducing upgrade costs.

Typical Application Scenarios

In a beverage bottling plant, the IMRIO02 manages a distributed network of field devices across the production line:

Digital inputs connect to photoelectric sensors detecting bottle presence on conveyors

Digital outputs control solenoid valves for bottle filling and capping mechanisms

PROFINET communication links to a central PLC, transmitting real-time status data (e.g., “bottle jam detected”)

The module’s IP65 protection allows installation near washdown areas, where periodic cleaning with high-pressure water occurs. Its wide temperature range ensures reliable operation in the plant’s fluctuating environment (10°C to 40°C during daily operations).

In a mining facility, the IMRIO02 is deployed in underground conveyor systems. It monitors pull cord switches (emergency stops) via digital inputs and controls conveyor brakes via outputs. Modbus TCP/IP communication sends data to a surface-level SCADA system, while its -30°C cold tolerance ensures functionality in unheated underground sections.

ABB IMRIO02

Related Model Recommendations

IMRIO01: Entry-level variant of IMRIO02 with 8 digital inputs/outputs, ideal for small-scale distributed systems.

IMRIO-EX16: Analog expansion module for IMRIO02, adding 16 channels (4-20 mA/0-10 V) for pressure/temperature sensing.

AC500-S PLC: ABB’s compact controller that pairs with IMRIO02 for distributed control in manufacturing cells.

CI854A: PROFINET adapter that enhances IMRIO02’s communication range in large facilities.

IMRIO-HD: Heavy-duty version of IMRIO02 with 3 kV isolation, designed for high-voltage industrial environments.

TB-IMRIO: Terminal block kit for IMRIO02, providing surge protection for field wiring in noisy electrical environments.

IMRIO03: Advanced model with 4G connectivity, enabling remote monitoring of IMRIO02-based systems in off-grid locations.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Mount IMRIO02 on a clean, grounded 35 mm DIN rail, ensuring 50 mm clearance for cooling. Use shielded twisted-pair cable (0.5-1.0 mm²) for field connections, with shields grounded at both ends to reduce EMI. Connect 24 V DC power via a 1.5 A fused supply, verifying polarity. For IP65 protection, install the optional housing and seal cable entries with M20 gland nuts. Configure protocols using ABB’s Automation Builder software before power-up.

Maintenance suggestions: Inspect IMRIO02 quarterly for loose connections, especially in high-vibration areas (e.g., near pumps). Check status LEDs: green indicates normal operation, flashing red signals communication faults. Clean vents with compressed air to prevent dust buildup. Test I/O channels annually by simulating inputs (e.g., shorting a sensor wire) and verifying output response. If expansion modules fail, isolate the issue by disconnecting them one by one. Replace IMRIO02 with ABB-approved units only, transferring configurations via software to minimize downtime.

Service and Guarantee Commitment

The IMRIO02 comes with a 3-year warranty covering defects in materials and workmanship. ABB’s technical support team provides 24/7 assistance for configuration, protocol troubleshooting, and integration with ABB/third-party systems, including access to online guides and video tutorials.

Customers receive free firmware updates during the warranty period, ensuring compatibility with new industrial protocols. ABB maintains regional stock of IMRIO02 and expansion modules, enabling next-day delivery for critical replacements. Our global service network offers on-site commissioning support, ensuring optimal module performance from day one—backed by ABB’s decades of expertise in industrial automation reliability.