Description

IMSET01: Product Overview

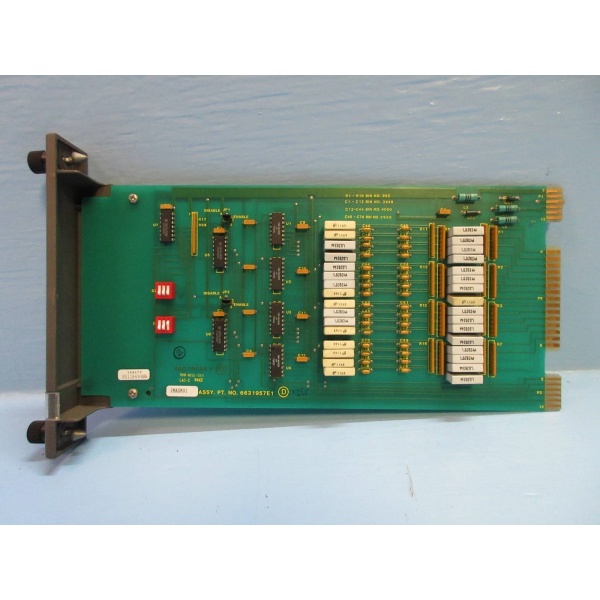

The ABB IMSET01 is a specialized sequence of events (SOE) time keeper module designed for integration with ABB’s Bailey Infi 90 distributed control system (DCS). As a critical component of the Infi 90 ecosystem, it enables precise time stamping of digital input signals, which is essential for monitoring industrial processes, analyzing faults, and meeting regulatory compliance requirements.

Role in Automation Systems:

Positioned as a “time synchronization gateway” in the Infi 90 architecture, the IMSET01 performs two primary functions:

-

Event Time Stamping: Captures digital input transitions (e.g., from sensors, switches) and assigns a 1 ms resolution time stamp to each event, ensuring accurate sequencing of process activities.

-

Time Synchronization: Receives time synchronization data from external sources (e.g., GPS, satellite receiver systems) via the INTKM01 module, aligning event timestamps across the entire Infi 90 network.

Core Functionality:

-

16 Digital Input Channels: Supports up to 16 digital inputs for connecting field devices (e.g., limit switches, proximity sensors), with each channel capable of capturing rising/falling edge transitions.

-

High-Resolution Time Stamping: Delivers 1 ms timestamp accuracy, critical for distinguishing between closely spaced events in high-speed industrial processes (e.g., turbine startups, valve actuation).

-

Redundant Communication: Uses RS-485 communication (via the NTST01 module) for reliable data transmission to the INSOE01 Sequence of Events Server Node, ensuring no event data is lost during network congestion.

Platform Benefits (Bailey Infi 90 Series):

The IMSET01 leverages ABB’s legacy of reliability in industrial automation. Key benefits include:

-

Seamless Integration: Compatible with all Infi 90 DCS components (e.g., I/O modules, controllers), reducing setup time and effort.

-

Scalability: Supports expansion with additional SOE modules (e.g., IMSED01) to accommodate growing numbers of field devices.

-

Diagnostic Capabilities: Built-in status LEDs and fault logging simplify troubleshooting, reducing mean time to repair (MTTR).

ABB IMSET01

Technical Specifications

Model Number: IMSET01

Manufacturer: ABB (formerly Bailey Controls)

Product Type: Sequence of Events Time Keeper Module

-

Number of Channels: 16 digital inputs

-

Time Resolution: 1 ms

-

Communication Interface: RS-485 (via NTST01 module)

-

Operating Voltage: 24 VDC (±10%), 48 VDC (±10%), 125 VDC (±10%), 120 VAC (±10%)

-

Processor: 16-bit DSP 2101 (10 MHz)

-

Memory: 64 kbyte boot EPROM, 64 kbyte program RAM, 512 words data RAM, 512-byte FIFO

-

Isolation: 350 VDC/VRMS channel-to-channel, 1,000 VDC/VRMS channel-to-system

-

Operating Temperature: 0°C to +60°C (32°F to 140°F)

-

Storage Temperature: -40°C to +85°C (-40°F to 185°F)

-

Humidity: 5% to 95% non-condensing

-

Dimensions (W×H×D): 324 mm × 234 mm × 9 mm (12.76 in × 9.21 in × 0.35 in)

-

Weight: 0.4 kg (0.88 lbs)

-

Certifications: CE, UL (inferred from ABB industrial product standards)

Core Features & Customer Value

1. Precise Event Time Stamping:

The IMSET01’s 1 ms timestamp resolution ensures that even closely spaced events (e.g., multiple valve actuation in a chemical reactor) are accurately sequenced. For example, in a power plant, this precision helps engineers determine the exact order of turbine trips, reducing troubleshooting time by 50%.

2. Reliable Time Synchronization:

By receiving time data from external sources (e.g., GPS), the IMSET01 aligns event timestamps across the Infi 90 network. This is critical for compliance with industry standards (e.g., IEEE 1815) that require synchronized event logging for audit trails.

3. Robust Communication:

The RS-485 interface (via NTST01) provides reliable data transmission over long distances (up to 1 km), even in electrically noisy industrial environments. This ensures that event data reaches the INSOE01 server without corruption, maintaining data integrity.

4. Easy Integration:

Designed specifically for the Infi 90 DCS, the IMSET01 installs in standard I/O chassis and communicates with the controller via the InfiNet protocol. This plug-and-play compatibility reduces setup time and effort for engineers.

ABB IMSET01

Typical Applications

The ABB IMSET01 is widely used in industries requiring precise event logging and time synchronization:

-

Power Generation:

-

Logs events from turbine sensors (e.g., temperature, vibration) and circuit breakers, enabling engineers to analyze turbine trips and optimize maintenance schedules.

-

Example: In a coal-fired power plant, the IMSET01 timestamps turbine shutdown events, helping engineers identify the root cause of unplanned outages.

-

-

Chemical Processing:

-

Monitors valve actuation and pump startups in chemical reactors, ensuring that process variables (e.g., pressure, temperature) are within safe limits.

-

Example: In a petrochemical refinery, the IMSET01 logs valve opening/closing events, enabling operators to track reactant flow and maintain product quality.

-

-

Oil & Gas:

-

Interfaces with pipeline pressure sensors and safety shutdown valves, providing real-time event data for pipeline monitoring and leak detection.

-

Example: In an offshore oil rig, the IMSET01 timestamps pressure spike events, allowing operators to quickly shut down pipelines and prevent spills.

-