Description

Detailed parameter table

| Parameter name | Parameter value |

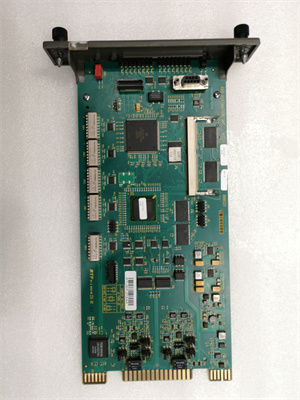

| Product model | INNIS21 |

| Manufacturer | ABB |

| Product category | Safety input module (safety I/O) |

| Number of safety inputs | 8 channels (normally closed contacts) |

| Safety integrity level | SIL 3 (per IEC 61508); PL e (per ISO 13849-1) |

| Operating voltage | 24 V DC ±10% |

| Maximum input current | 5 mA per channel |

| Response time | ≤ 10 ms |

| Isolation | 5 kV AC (channel-to-bus, channel-to-channel) |

| Operating temperature | -25°C to +70°C |

| Dimensions (W×H×D) | 22 mm × 105 mm × 115 mm |

| Installation method | DIN rail mounting via safety terminal base |

| Diagnostic features | Channel-level fault detection, open/short circuit monitoring, LED status indicators |

| Compliance | IEC 61508, ISO 13849-1, CE, UL 1998 |

ABB INNIS21

Product introduction

The INNIS21 is a high-integrity safety input module from ABB, designed to monitor critical safety devices in industrial automation systems. As a key component of ABB’s safety I/O portfolio, it acts as a reliable interface between safety sensors—such as emergency stop buttons, light curtains, and guard door interlocks—and safety controllers, ensuring hazardous machinery stops immediately when risks are detected.

Engineered for seamless integration with ABB’s safety controllers (e.g., AC500-S safety PLCs), the INNIS21 provides 8 channels of safety input monitoring, making it suitable for medium-scale safety circuits. Its SIL 3 and PL e certifications validate its ability to prevent dangerous failures, making it indispensable in applications where operator safety and machine protection are paramount. Whether deployed in automotive assembly lines or pharmaceutical manufacturing, the INNIS21 forms the foundation of robust safety architectures, translating sensor signals into actionable safety responses.

Core advantages and technical highlights

SIL 3 safety certification

The INNIS21 meets SIL 3 (IEC 61508) and PL e (ISO 13849-1) standards, ensuring it can be used in the most safety-critical applications. In a robotic welding cell, this certification guarantees that the module will reliably detect a pressed emergency stop button, triggering a machine shutdown within 10 ms—fast enough to prevent injury. Its low probability of dangerous failure (PFD < 10⁻³) minimizes risk in high-hazard environments.

Advanced diagnostics

Equipped with channel-level monitoring, the INNIS21 detects open circuits, short circuits, and wire breaks in real time. In a food packaging line, if a guard door interlock wire frays, the module immediately flags the fault via its red LED and communicates it to the safety controller, preventing unplanned downtime by enabling targeted repairs. This diagnostic capability reduces troubleshooting time by up to 70% compared to non-diagnostic safety modules.

Flexible integration

The INNIS21 seamlessly connects to ABB’s AC500-S safety PLCs and third-party safety controllers via safety bus protocols. In a semiconductor cleanroom, it integrates with light curtains, emergency stops, and pressure-sensitive mats, consolidating their signals into a single safety loop. Its compact 22 mm width allows dense mounting in control cabinets, saving space in safety-critical enclosures.

Typical application scenarios

In an automotive stamping plant, the INNIS21 serves as the safety nerve center for a 500-ton press:

- Monitors 4 emergency stop buttons (one at each operator station)

- Tracks 2 guard door interlocks on the press access panels

- Reads signals from 2 light curtains guarding the material loading area

When any safety device activates—e.g., an operator breaking the light curtain—the INNIS21 sends an immediate shutdown command to the safety PLC, which cuts power to the press motor within 10 ms. Its 5 kV isolation protects against electrical noise from the press’s hydraulic systems, ensuring false triggers are eliminated.

In a pharmaceutical filling line, the INNIS21 monitors safety interlocks on sterile enclosure doors and hands-free operation sensors. It ensures the line only operates when doors are sealed (preventing contamination) and operators are clear of moving parts, aligning with FDA regulations for safe drug manufacturing.

ABB INNIS21

Related model recommendations

- INNIS11: 4-channel version of the INNIS21, ideal for smaller safety circuits (e.g., single-machine guards).

- INNOS21: Safety output module that pairs with the INNIS21, triggering machine shutdowns based on input signals.

- AC500-S PM595-S: ABB safety PLC that processes data from the INNIS21to execute safety logic.

- SS822: ABB safety relay compatible with the INNIS21in mixed safety systems requiring relay-based backup.

- CL200: ABB light curtain system that connects directly to the INNIS21’s safety inputs.

- CE4T-10: Emergency stop button designed for use with the INNIS21in harsh industrial environments.

- INNIA21: Analog safety input module that complements the INNIS21in safety loops requiring variable signals (e.g., pressure monitors).

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the INNIS21, ensure the control cabinet is de-energized and locked out. Mount the safety terminal base on a 35 mm DIN rail, leaving 20 mm clearance for airflow. Use 0.5-1.5 mm² shielded twisted-pair cables for safety device connections, grounding shields at both ends to minimize noise. Connect field devices to terminals 1-16 (channels 1-8), ensuring all contacts are normally closed as required by the safety logic. Torque terminal screws to 0.5 Nm and verify polarity before powering on.

Maintenance suggestions

Daily checks of the INNIS21 involve verifying green LEDs for active channels and power; red LEDs indicate faults (check safety controller logs for details). Test each channel monthly by activating the connected safety device and confirming the module registers the signal. Every six months, inspect wiring for corrosion and tighten terminals. If a channel fails, isolate the fault by swapping devices between channels—replace the INNIS21 with an ABB-approved spare if internal faults are confirmed, ensuring the replacement is reconfigured with the same safety parameters.

Service and guarantee commitment

The INNIS21 is backed by a 3-year warranty, covering defects in materials and workmanship under normal operating conditions. ABB’s safety systems technical team provides specialized support, including help with safety loop validation, SIL verification, and integration with ABB safety controllers.

Customers receive access to certified safety manuals and test procedures for the INNIS21. ABB offers on-site safety audits to ensure compliance with global standards. With factory-calibrated replacements available globally, downtime in safety-critical systems is minimized. Trust the INNIS21 to protect your workforce, backed by ABB’s expertise in industrial safety solutions.