Description

Detailed parameter table

| Parameter name | Parameter value |

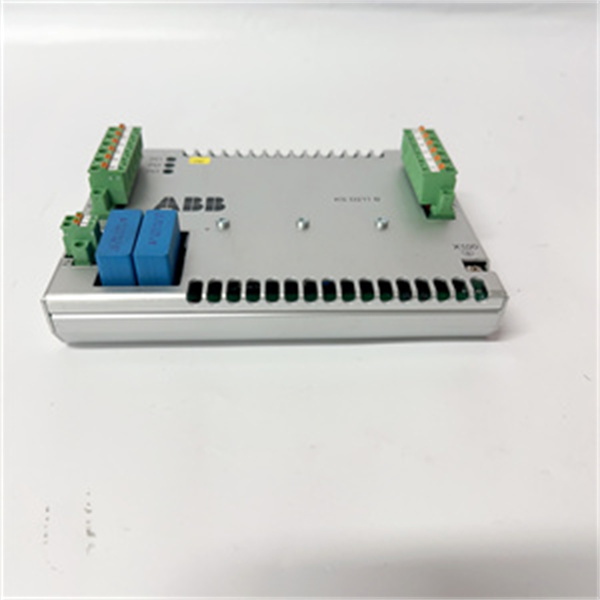

| Product model | KSD211B 3BHE022455R1101 |

| Manufacturer | ABB |

| Product category | Safety relay module (emergency stop monitoring) |

| Safety integrity level | SIL 3 (per IEC 61508) |

| Performance level | PL e (per ISO 13849-1) |

| Number of safety inputs | 4 (dual-channel emergency stop, safety gate) |

| Safety outputs | 2 x NO (250 V AC/3 A), 1 x NC (250 V AC/3 A) |

| Operating voltage | 24 V DC ±15% |

| Response time | <100 ms |

| Operating temperature | -25°C to 70°C |

| Power consumption | Max 2 W |

| Protection rating | IP20 |

| Mounting type | DIN rail mount (35 mm) |

| Dimensions | 22.5mm × 100mm × 75mm |

| Certifications | CE, UL, ATEX, IEC 61508, ISO 13849-1 |

ABB KSD211B 3BHE022455R1101

Product introduction

The KSD211B 3BHE022455R1101 is a high-integrity safety relay module from ABB, engineered to monitor and control safety-critical functions in industrial automation systems. As a key component in ABB’s safety portfolio, this module acts as a dedicated safety layer between field devices (such as emergency stop buttons, safety gates, and light curtains) and control systems like the PCD235A101 3BHE032025R0101 PLC, ensuring rapid response to hazardous conditions.

Unlike standard relays, the KSD211B is designed to meet the most stringent safety standards (SIL 3, PL e), making it ideal for applications where human safety and equipment protection are paramount—from robotic workcells to heavy machinery. Whether deployed in automotive factories, packaging lines, or chemical plants, this module provides failsafe monitoring, preventing unsafe states and enabling safe shutdowns when hazards are detected.

Core advantages and technical highlights

SIL 3/PL e safety certification: The KSD211B is certified to IEC 61508 (SIL 3) and ISO 13849-1 (PL e), representing the highest safety integrity levels for industrial applications. In a robotic welding cell, this certification ensures the module reliably detects emergency stop signals from dual-channel buttons, triggering a safe stop of the KUC321AE HIEE300698R1 robot controller within 100 ms—meeting the safety requirements for zones where operators work in close proximity to moving equipment.

Dual-channel input design: Equipped with 4 safety inputs configured as two dual-channel pairs, the module provides redundant monitoring of critical safety devices. For example, in a press machine application, it can monitor both a safety gate switch and an emergency stop button, with each device connected to two separate inputs. This redundancy prevents single-point faults from masking hazardous conditions, ensuring the machine stops if either channel detects a fault.

Fast response time: With a response time of <100 ms, the KSD211B ensures rapid activation of safety outputs when a hazard is detected. In a high-speed packaging line, this speed means the module can stop conveyor motors (via safety contactors) within 50 ms of a light curtain being breached, preventing collisions between operators and moving parts. The fast response also minimizes production downtime by enabling quick resumption once the hazard is resolved.

Seamless integration with control systems: The module’s safety outputs interface directly with both machinery (e.g., motor contactors) and control systems like the PCD235A101 PLC. In a food processing plant, it sends a “safety triggered” signal to the PLC via the DAPI100 3AST000929R109 digital input module, allowing the controller to log the event and initiate appropriate recovery procedures. This integration creates a closed-loop safety system, combining real-time monitoring with diagnostic reporting.

Robust fault detection: The KSD211B continuously self-monitors for internal faults (e.g., relay sticking, voltage fluctuations) and external wiring errors (e.g., short circuits, open circuits). In a pharmaceutical manufacturing facility, this self-diagnosis alerts maintenance teams to a degraded safety gate sensor via the HMI80 panel, enabling proactive repairs before a fault compromises safety. The module’s fault-signaling output ensures unsafe conditions are never masked.

Typical application scenarios

In an automotive assembly line, the KSD211B 3BHE022455R1101 monitors dual-channel emergency stop buttons and safety gates around an IRB 6700 robot cell. When an operator presses an emergency stop, the module detects the signal within 20 ms and activates its safety outputs, cutting power to the robot’s servo drives (via the 3HAC14550-408A interface) and sending a fault signal to the PCD235A101 PLC. Its SIL 3 certification ensures this process is reliable even in the presence of electrical noise from welding equipment.

In a chemical processing plant, the module safeguards a reactor vessel by monitoring safety interlocks on access doors and pressure relief valves. It works alongside the CI858-1 3BSE018137R1 communication module to transmit safety status to the SCADA system, ensuring operators are immediately alerted to any breaches. The KSD211B’s wide operating temperature range (-25°C to 70°C) allows it to function reliably in the plant’s unconditioned control room, while its compact design saves space in crowded cabinets.

ABB KSD211B 3BHE022455R1101

Related model recommendations

KSD221B 3BHE022456R1101: ABB’s safety relay with additional inputs for monitoring light curtains and two-hand controls.

PCD235A101 3BHE032025R0101: ABB’s PLC that receives safety status signals from the KSD211B.

DAPI100 3AST000929R109: ABB’s digital input module that interfaces the safety relay with the PLC.

PPE091A101 3BHE044481R0101: ABB’s power supply module that delivers stable 24 V DC to the safety relay.

CI858-1 3BSE018137R1: ABB’s communication module that transmits safety data to SCADA systems.

TB857: ABB’s surge protection terminal block that enhances the module’s immunity to voltage transients.

HMI80: ABB’s touchscreen panel that visualizes safety status and fault diagnostics from the KSD211B.

Installation, commissioning and maintenance instructions

Installation preparation: Mount the KSD211B 3BHE022455R1101 on a 35 mm DIN rail, ensuring at least 10mm clearance from adjacent devices for cooling. Connect safety inputs (emergency stops, safety gates) using 0.5-1 mm² shielded twisted-pair cable, with dual-channel devices wired to separate input pairs. Wire safety outputs to motor contactors or control system inputs, using 1 mm² cable for currents up to 3 A. Power the module with 24 V DC from a dedicated safety power supply (e.g., PPE091A101), ensuring isolation from non-safety circuits. Required tools include a DIN rail cutter, torque screwdriver (0.5 Nm), and a multimeter. Power off all systems during installation.

Commissioning steps: Verify wiring continuity and insulation resistance (>100 MΩ) between inputs, outputs, and ground. Test each safety input by activating the connected device (e.g., pressing an emergency stop) and confirming the module’s safety outputs de-energize within 100 ms (measured with an oscilloscope). Validate fault detection by simulating a wiring error (e.g., open circuit) and ensuring the module enters a safe state and activates the fault output. Document all test results for safety compliance records.

Maintenance suggestions: Inspect quarterly for loose connections, dust accumulation, and LED status (power: green, safe state: yellow, fault: red). Clean the module with a dry cloth—do not use compressed air, as it may dislodge internal components. Test safety functionality semi-annually by activating all connected safety devices and verifying proper response. Replace the module every 10 years (or sooner if subjected to frequent fault conditions) to maintain safety integrity. Use only ABB-certified replacements to ensure compliance with SIL 3/PL e standards.

Service and guarantee commitment

The KSD211B 3BHE022455R1101 comes with a 5-year warranty from installation, covering manufacturing defects and ensuring compliance with safety certifications. ABB guarantees technical support response within 2 hours for safety-critical applications, with on-site troubleshooting available in 48 hours for qualified industrial facilities. The module includes access to safety compliance documentation and test procedures for the entire warranty period. Extended service contracts offer annual safety audits, functional testing, and priority support, ensuring the module maintains its safety integrity throughout its 10-year design lifespan. Customers receive dedicated online resources, including wiring diagrams, safety manual excerpts, and certification documents specific to this model.