Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | KUC321AE HIEE300698R1 |

| Manufacturer | ABB |

| Product category | Robot control unit (main processor module) |

| Compatible robot series | IRB 4600, IRB 6700, IRB 7600 |

| Processor | Dual-core 1.8 GHz industrial CPU |

| Memory | 4 GB RAM, 32 GB SSD |

| Supported programming languages | RAPID, C# (for add-on applications) |

| Communication interfaces | 4 x Ethernet (1000 Mbps), 2 x PROFINET IO, 1 x USB 3.0 |

| Operating voltage | 24 V DC ±15% |

| Power consumption | Max 25 W |

| Operating temperature | 0°C to 45°C |

| Protection rating | IP20 (module), IP54 (with control cabinet) |

| Mounting type | Cabinet mount (DIN rail) |

| Dimensions | 180mm × 250mm × 120mm |

| Certifications | CE, UL, ISO 13849-1 (PL d), IEC 61508 (SIL 2) |

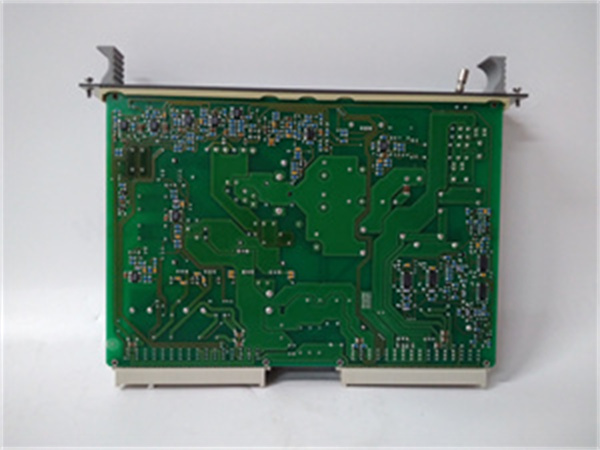

ABB KUC321AE HIEE300698R1

Product introduction

The KUC321AE HIEE300698R1 is a high-performance robot control unit from ABB, serving as the central processing module for mid-to-large industrial robot systems. As the “brain” of ABB’s robotic controllers, this unit executes motion control algorithms, processes sensor data, and manages communication with peripheral devices—seamlessly integrating with servo drive interfaces like the 3HAC14550-408A to deliver precise robotic operations.

Unlike basic robot controllers, the KUC321AE combines powerful computing capabilities with advanced connectivity, making it ideal for applications requiring adaptive motion control, such as automotive assembly, material handling, and machine tending. Whether coordinating multi-robot cells or integrating with plant-wide MES systems, this control unit ensures smooth operation, high throughput, and easy scalability in complex automation environments.

Core advantages and technical highlights

Powerful processing performance: Equipped with a dual-core 1.8 GHz industrial CPU and 4 GB RAM, the KUC321AE handles complex RAPID programs with cycle times as low as 1 ms. In an automotive welding line, this allows the unit to simultaneously execute path planning for a 6-axis IRB 6700 robot, process real-time data from 3D vision systems, and adjust motion parameters based on weld seam feedback—all without performance degradation. The 32 GB SSD provides reliable storage for program libraries and log files, even in high-vibration environments.

Advanced motion control capabilities: The control unit leverages ABB’s proprietary motion control algorithms to deliver ±0.05 mm path accuracy, critical for precision tasks like electronic component assembly. Its adaptive control features compensate for payload variations and external disturbances; for example, in a palletizing application, the KUC321AE automatically adjusts acceleration rates when switching from empty to full pallets, reducing cycle times by 10% while maintaining stability. When paired with the 3HAC14550-408A servo interface, it achieves seamless synchronization across all robot axes.

Seamless system integration: With four Gigabit Ethernet ports and dual PROFINET IO interfaces, the KUC321AE integrates effortlessly with PLC systems like the PCD235A101 3BHE032025R0101, communication gateways such as the 500CIM05 1MRB150077R1/B, and field devices including the AI880-1 analog module. In a food and beverage packaging plant, this connectivity enables the robot controller to receive production orders from the MES, adjust pick-and-place patterns based on sensor data, and transmit cycle time metrics to the PLC—creating a fully connected automation loop.

Flexible programming and customization: Supporting ABB’s RAPID language and C# for add-on applications, the KUC321AE allows engineers to develop custom solutions for specialized tasks. For instance, in a semiconductor handling application, a C# plugin can be integrated to implement machine learning-based error detection, analyzing sensor data from the DTCC901B digital module to predict gripper wear. The unit’s open architecture also supports OPC UA, facilitating data exchange with third-party software for predictive maintenance or quality analysis.

Robust and reliable design: Built to withstand industrial environments, the KUC321AE features a fanless design with wide temperature tolerance (0°C to 45°C) and resistance to shock and vibration. Its 24 V DC power supply with surge protection ensures stable operation even in facilities with electrical noise, such as foundries or stamping plants. The module’s IP20 rating (with IP54 when installed in a control cabinet) protects against dust and moisture, ensuring long-term reliability in harsh conditions.

Typical application scenarios

In an automotive body shop, the KUC321AE HIEE300698R1 controls two IRB 6700 robots working in tandem to weld car door frames. It processes data from laser vision systems (via PROFINET IO) to adjust weld paths in real time, compensating for sheet metal variations. The control unit coordinates with the 3HAC14550-408A servo interface to synchronize robot movements, ensuring weld seams are precise within ±0.1 mm. Integration with the PCD235A101 PLC allows the robots to pause automatically if the AI880-1 module detects incorrect gas pressure, preventing defective welds.

In a logistics distribution center, the control unit manages an IRB 4600 robot equipped with a vacuum gripper for case palletizing. It receives order data from the warehouse management system (via Ethernet) and generates optimal pallet patterns using built-in algorithms. The KUC321AE adjusts gripper pressure based on feedback from the DTCC901B digital module, ensuring secure handling of varying package weights. Diagnostic data, such as cycle counts and error logs, is transmitted to the MES via the 500CIM05 communication module, enabling performance monitoring and maintenance scheduling.

ABB KUC321AE HIEE300698R1

Related model recommendations

KUC322AE HIEE300699R1: A higher-performance variant with a quad-core CPU, ideal for multi-robot cells with complex coordination requirements.

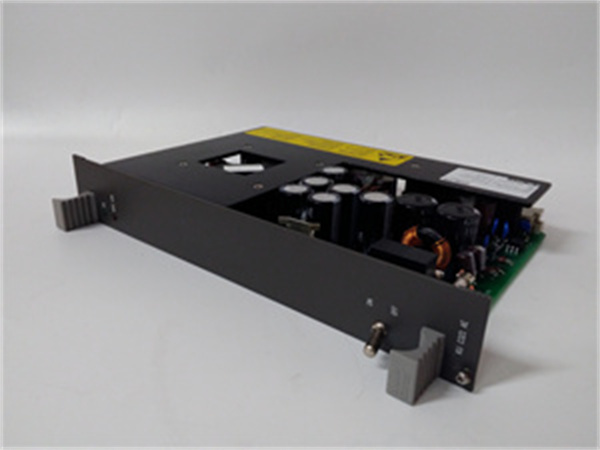

3HAC14550-408A: ABB’s servo drive interface that works with the KUC321AE to control robot axes.

PCD235A101 3BHE032025R0101: ABB’s PLC that integrates with the control unit for cell-level automation.

500CIM05 1MRB150077R1/B: ABB’s communication module that extends the robot’s connectivity to enterprise systems.

AI880-1: ABB’s analog input module that provides process data (e.g., pressure, temperature) to the KUC321AE.

DTCC901B: ABB’s digital control module that monitors safety interlocks and gripper status for the robot.

DSQC 1031: ABB’s vision processing unit that enhances the KUC321AE with 3D object recognition capabilities.

Installation, commissioning and maintenance instructions

Installation preparation: Mount the KUC321AE HIEE300698R1 on a DIN rail in the robot control cabinet, ensuring at least 100mm clearance for ventilation. Connect 24 V DC power using 1.5mm² shielded cable, with a 2A fuse for protection. Attach Ethernet cables (Cat 6a) to PROFINET IO devices (e.g., 3HAC14550-408A) and plant networks, and USB devices (e.g., programming pendrives). Required tools include a DIN rail cutter, wire strippers, and a network tester. Power off the cabinet during installation.

Commissioning steps: Use ABB’s RobotStudio software to load RAPID programs and configure communication parameters (IP addresses, PROFINET device names). Calibrate the robot using the built-in calibration tool, verifying joint positions with a laser tracker. Test motion sequences at reduced speed to ensure path accuracy, then incrementally increase to full operating speed. Validate integration with the PCD235A101 PLC by exchanging test signals (e.g., robot ready, start command). Perform safety validation by testing emergency stops and confirming compliance with PL d requirements. Save configurations to the SSD and create a backup.

Maintenance suggestions: Inspect monthly for loose connections, dust accumulation, and LED status (power: green, run: flashing green, fault: red). Clean ventilation vents with compressed air to prevent overheating. Check Ethernet cable integrity quarterly, especially in areas with mechanical stress. Update firmware annually via USB or Ethernet (with password protection) to access new features and security patches. Monitor SSD health semi-annually using RobotStudio’s diagnostic tools, replacing the drive if wear indicators exceed 90%. Replace with an ABB-certified module if CPU or memory errors persist.

Service and guarantee commitment

The KUC321AE HIEE300698R1 comes with a 3-year warranty from installation, covering manufacturing defects and ensuring compliance with published performance specifications. ABB guarantees technical support response within 2 hours for critical robotic applications, with on-site troubleshooting available in 48 hours for qualified customers. The unit includes 2 years of free access to RobotStudio software and firmware updates. Extended service contracts offer preventive maintenance, performance optimization, and priority support, ensuring reliable operation throughout its 10-year design lifespan. Customers receive dedicated online resources, including programming guides, integration manuals, and troubleshooting videos specific to this model.