Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | LDMUI-001 61320946C |

| Manufacturer | ABB |

| Product category | Local display and user interface module (for drives and controllers) |

| Display type | 2-line alphanumeric LCD, backlit |

| Operating keys | 4 membrane keys (Up, Down, Enter, Escape) |

| Communication interface | RS-485 (Modbus RTU) |

| Supported devices | ABB ACS880, ACS580, and ACS550 series drives |

| Operating voltage | 24 VDC ±10% |

| Power consumption | Max 2 W |

| Operating temperature | -10°C to 50°C |

| Protection rating | IP65 (front panel), IP20 (rear connections) |

| Dimensions | 70mm × 50mm × 25mm |

| Weight | 0.15kg |

| Certifications | CE, UL, RoHS |

| Mounting type | Panel mount (flush) |

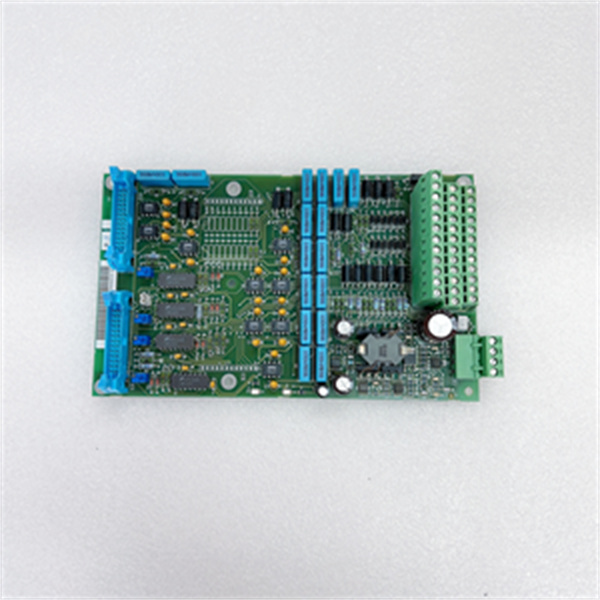

ABB LDMUI-001 61320946C

Product introduction

The ABB LDMUI-001 61320946C is a compact local display and user interface module designed to provide convenient on-site monitoring and configuration of ABB’s industrial drives, including the ACS880, ACS580, and ACS550 series. As a dedicated interface device, it serves as a bridge between operators and the drive system, enabling quick parameter adjustments, status checks, and troubleshooting without the need for a separate programming tool or HMI.

Featuring a backlit alphanumeric LCD and intuitive membrane keys, the ABB LDMUI-001 61320946C offers a user-friendly way to interact with connected drives. It supports real-time display of critical drive parameters such as motor speed, current, voltage, and fault codes, while allowing operators to modify settings like acceleration/deceleration times, torque limits, and operating modes directly at the drive location.

Within industrial automation setups, the ABB LDMUI-001 61320946C enhances operational efficiency by providing immediate access to drive functions. Its rugged design and IP65 front panel protection make it suitable for installation in harsh industrial environments, from factory floors to outdoor equipment enclosures, ensuring reliable operation even in dusty or wet conditions.

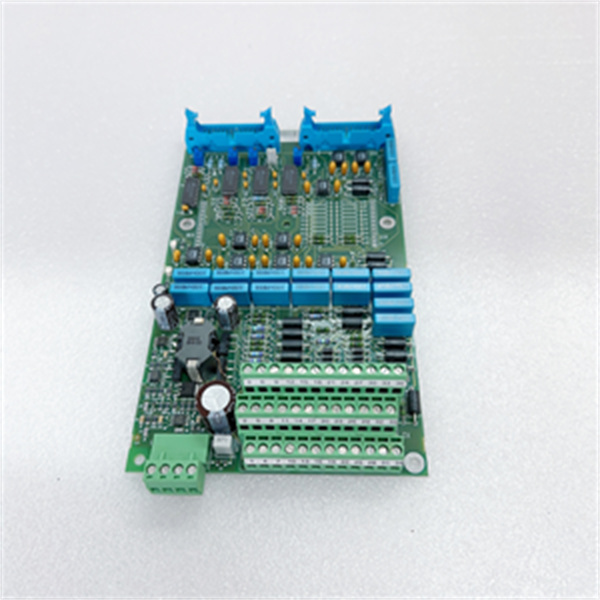

Core advantages and technical highlights

Simplified drive management: The ABB LDMUI-001 61320946C streamlines drive configuration and monitoring with its 2-line LCD display and 4-key operation. Operators can navigate through drive menus, view real-time data, and adjust parameters in minutes, reducing the need for specialized training or laptop-based tools. This simplicity is particularly valuable during commissioning, maintenance, or emergency situations where quick access to drive settings is critical.

Wide drive compatibility: Designed to work seamlessly with ABB’s ACS880, ACS580, and ACS550 drive series, the ABB LDMUI-001 61320946C eliminates compatibility issues often encountered with third-party interfaces. It automatically recognizes the connected drive model and adapts its menu structure to display relevant parameters, ensuring a consistent user experience across different drive types and sizes.

Durable industrial design: With an IP65-rated front panel, the ABB LDMUI-001 61320946C withstands dust ingress and water jets, making it suitable for installation in washdown areas (e.g., food processing plants) or outdoor environments. Its operating temperature range of -10°C to 50°C ensures reliable performance in cold storage facilities or heated industrial zones, eliminating the need for protective enclosures in most applications.

Modbus RTU connectivity: Equipped with an RS-485 port supporting Modbus RTU, the ABB LDMUI-001 61320946C enables communication with the drive’s control system. This allows the interface to mirror data from the drive’s internal network, ensuring operators see the same parameters as the central control system. It also supports parameter upload/download, enabling quick replication of settings across multiple drives in a system.

Compact and easy to install: The ABB LDMUI-001 61320946C‘s small form factor (70mm × 50mm × 25mm) fits easily into tight spaces on drive enclosures or control panels. Its flush panel mount design requires only a 60mm × 40mm cutout, simplifying installation. The module connects to the drive via a standard 5-pin M12 connector, reducing wiring time and ensuring secure connections.

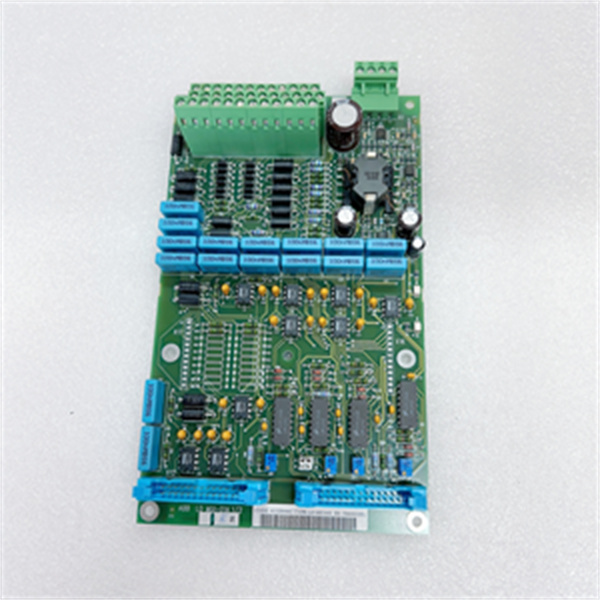

Typical application scenarios

In manufacturing facilities, the ABB LDMUI-001 61320946C is installed on ACS880 drives powering conveyor systems. Operators use it to adjust conveyor speed, monitor motor current to detect jams, and reset fault codes without leaving the production line. Its IP65 rating allows installation near washdown stations in food or pharmaceutical plants, where hygiene requirements demand frequent cleaning.

Within water and wastewater treatment plants, the ABB LDMUI-001 61320946C interfaces with ACS580 drives controlling pumps. It displays flow rates derived from drive speed, allows adjustment of pressure setpoints, and alerts operators to overload conditions via fault codes. Its rugged design withstands the humid, dusty environments typical of pump stations.

In HVAC systems for commercial buildings, the ABB LDMUI-001 61320946C is used with ACS550 drives managing fan and blower motors. Facility technicians use it to optimize airflow by adjusting motor speed, monitor energy consumption, and troubleshoot issues like phase loss or overheating. Its compact size fits neatly on drive enclosures in mechanical rooms with limited space.

ABB LDMUI-001 61320946C

Related model recommendations

ABB LDUCB-01: A communication adapter that extends the ABB LDMUI-001 61320946C‘s connectivity to Ethernet/IP networks, enabling remote monitoring.

ABB ACS880-01-04A1-3: A 1.5kW industrial drive commonly paired with the ABB LDMUI-001 61320946C for small to medium motor applications.

ABB Drive composer: Software that complements the ABB LDMUI-001 61320946C by providing advanced drive configuration and data logging on a PC.

ABB M12 cable assembly: A shielded cable for connecting the ABB LDMUI-001 61320946C to the drive, ensuring reliable communication in noisy environments.

ABB DPAD-02: A handheld programming device that offers portability beyond the fixed ABB LDMUI-001 61320946C for multi-drive systems.

ABB AC500 PLC: A controller that integrates with drives via the ABB LDMUI-001 61320946C‘s Modbus interface for centralized system control.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the ABB LDMUI-001 61320946C, verify the panel cutout dimensions (60mm × 40mm) and ensure the mounting surface is clean and flat. Check that the operating voltage (24 VDC ±10%) matches the drive’s auxiliary power supply. Required tools include a hole saw or panel cutter, torque screwdriver (0.3-0.5 Nm), and a small flathead screwdriver for terminal connections. Use the provided M12 connector to link the module to the drive, ensuring the cable length does not exceed 5 meters to maintain communication integrity.

Maintenance suggestions: Inspect the ABB LDMUI-001 61320946C semi-annually for dust accumulation on the display or key membrane; clean with a soft, dry cloth. Check the cable connection for tightness and signs of corrosion, especially in humid environments. Test the display and keys quarterly by navigating through drive menus and verifying all functions operate correctly. If the backlight fails or keys become unresponsive, replace the module with an ABB-approved unit to ensure compatibility with the drive system.

Service and guarantee commitment

The ABB LDMUI-001 61320946C comes with a 24-month warranty from the date of installation, covering manufacturing defects and ensuring proper functionality with compatible ABB drives. ABB guarantees replacement of faulty units within 48 hours for critical applications, minimizing downtime in drive operation.

Technical support includes access to ABB’s drive specialists, available for assistance with installation, menu navigation, and troubleshooting. Online resources include user manuals, quick-start guides, and compatibility charts specific to the ABB LDMUI-001 61320946C. Customers can opt for extended service contracts that include annual system checks and priority support, ensuring the module remains a reliable interface throughout its 8-year design lifespan.