Description

ABB MB805: Precision – Driven Force Sensor Excellence

Product Basics

The ABB MB805 is a high – performance force sensor meticulously crafted by ABB, a globally renowned leader in industrial automation and power technology. This sensor is designed to accurately measure forces within industrial settings, playing a pivotal role in ensuring the precision and efficiency of various manufacturing and production processes.

Technical Specifications at a Glance

| Parameter | Details |

| Measurement Range | Tailored to handle a wide spectrum of force magnitudes, suitable for both delicate operations and heavy – duty industrial applications. Specific range details can be customized according to user requirements. |

| Accuracy | Boasts an extremely high – level of accuracy, with minimal error margins. This ensures that the measured force values are highly reliable, crucial for maintaining product quality in precision – demanding industries. |

| Resolution | Offers a high – resolution output, capable of detecting even the slightest changes in force. This enables operators to make fine – tuned adjustments in the production process. |

| Output Signal | Provides a stable and standardized output signal, which can be easily integrated with other components in an industrial control system, such as programmable logic controllers (PLCs) or data acquisition systems. |

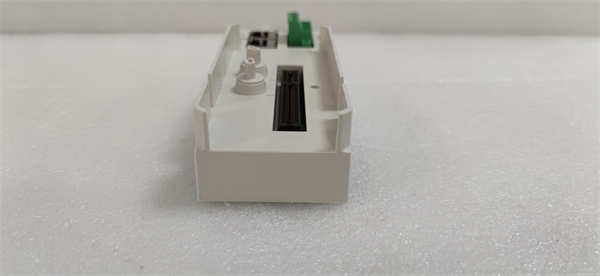

| Mechanical Design | Constructed with a robust and durable housing, the MB805 is engineered to withstand harsh industrial environments, including high temperatures, vibrations, and mechanical stress. Its compact design also allows for easy installation in various setups. |

| Power Requirements | Operates on a standard industrial power supply, ensuring compatibility with existing factory infrastructure. Power consumption is optimized to minimize energy usage without sacrificing performance. |

ABB MB805

Core Functionality and Operation

The ABB MB805 functions by converting the applied force into an electrical signal. When a force is exerted on the sensor, it deforms a sensing element within the device. This deformation causes a change in an electrical property, such as resistance or capacitance, which is then measured and converted into a proportional electrical signal. The sensor’s advanced signal – processing algorithms then refine this signal, removing any noise or interference to provide a clean and accurate representation of the applied force.

Key Features and Benefits

Exceptional Precision: The high – accuracy and resolution of the MB805 make it ideal for applications where precise force control is essential. In industries like electronics manufacturing, where delicate components need to be handled with care, the sensor can accurately measure the forces involved in processes such as pick – and – place operations. This precision helps to prevent damage to components and ensures consistent product quality.

Reliability in Harsh Environments: With its rugged construction and ability to operate under extreme conditions, the MB805 is a reliable choice for industrial settings. In automotive manufacturing plants, for example, where there are high levels of vibration and temperature fluctuations, the sensor can continue to function accurately, providing real – time force data for processes like robotic assembly.

Easy Integration: The standardized output signal of the MB805 allows for seamless integration into existing industrial automation systems. It can be easily connected to PLCs, which can then use the force data to control other machinery or make decisions in the production process. This ease of integration reduces the complexity and cost of system upgrades.

Customizability: ABB offers a degree of customizability for the MB805. Users can specify the measurement range, output signal type, and other parameters to suit their specific application requirements. This flexibility makes the sensor suitable for a wide variety of industries and processes.

Typical Application Scenarios

Robotics and Automation: In robotic applications, the MB805 is used to measure the forces exerted by robotic arms during tasks such as material handling, assembly, and surface finishing. By providing real – time force feedback, the sensor enables robots to perform tasks with greater precision and adaptability. For example, in a precision assembly line for medical devices, the robotic arm equipped with the MB805 can accurately apply the right amount of force when connecting small components, ensuring a secure and reliable connection.

Quality Control and Testing: The sensor is also widely used in quality control and testing processes. In the manufacturing of consumer goods, such as smartphones, the MB805 can be used to measure the force required to press buttons or close lids. This data can then be used to ensure that the products meet the required quality standards. In addition, in material testing laboratories, the sensor can be used to measure the tensile, compressive, and shear forces of various materials, providing valuable data for material research and development.

Packaging and Labeling: In the packaging industry, the MB805 plays a crucial role in ensuring that products are packaged correctly. It can be used to measure the force applied during the sealing process of packages, ensuring that the seals are tight and secure. In labeling applications, the sensor can measure the force required to apply labels to products, ensuring that the labels are applied evenly and firmly.

ABB MB805

Installation and Maintenance

Installation: Installing the ABB MB805 is a straightforward process. The sensor comes with clear installation instructions and mounting brackets. When installing, it is important to ensure that the sensor is properly aligned and securely fastened to the surface where the force will be applied. Care should also be taken to connect the sensor’s wiring correctly, following the electrical safety standards.

Maintenance: Regular maintenance of the MB805 is essential to ensure its optimal performance. This includes periodic cleaning of the sensor to remove any dust, debris, or contaminants that may affect its accuracy. The sensor’s calibration should also be checked and adjusted regularly, using a calibrated reference force source. In the event of any malfunction or damage, ABB provides a comprehensive range of replacement parts and technical support to ensure that the sensor can be quickly repaired or replaced.

Service and Support

ABB offers a comprehensive service and support package for the MB805. Their global network of technical experts is available to provide assistance with installation, calibration, and troubleshooting. In addition, ABB provides regular software updates and firmware upgrades to enhance the sensor’s performance and functionality. For customers who require additional support, ABB offers extended service contracts that include preventive maintenance services, priority technical support, and on – site training. With ABB’s long – standing reputation for quality and reliability, customers can be confident in the performance and support of the MB805 in their industrial applications.