Description

MG200Q2YS40: Product Overview

The ABB MG200Q2YS40 is an industrial servo motor designed to deliver high-precision motion control for demanding industrial applications. As part of ABB’s extensive servo motor portfolio, it is engineered to meet the rigorous requirements of automated machinery, robotics, and advanced manufacturing systems.

Role in Automation Systems:

The MG200Q2YS40 serves as a critical component in industrial automation systems, acting as the “muscle” that executes precise movements dictated by controllers (e.g., PLCs, CNC systems). It converts electrical signals from the controller into mechanical motion, enabling tasks such as:

-

Positioning robotic arms for assembly or welding.

-

Controlling the speed of conveyor belts or machine tools.

-

Maintaining torque for material handling equipment (e.g., hoists, grippers).

Core Functionality:

-

Precision Control: Delivers accurate position, speed, and torque control, with high resolution for fine-tuned adjustments.

-

Dynamic Response: Enables rapid acceleration and deceleration, critical for high-speed automation tasks.

-

Reliability: Built with industrial-grade components to withstand harsh environments (e.g., vibration, temperature fluctuations).

Platform Benefits (ABB Servo Systems):

The MG200Q2YS40 leverages ABB’s expertise in servo technology, offering:

-

Compatibility: Seamlessly integrates with ABB’s servo drives and controllers (e.g., ACS880 series) for optimized performance.

-

Scalability: Suitable for a wide range of applications, from small robotic cells to large-scale manufacturing lines.

-

Energy Efficiency: Designed to minimize power consumption while maintaining performance, reducing operational costs.

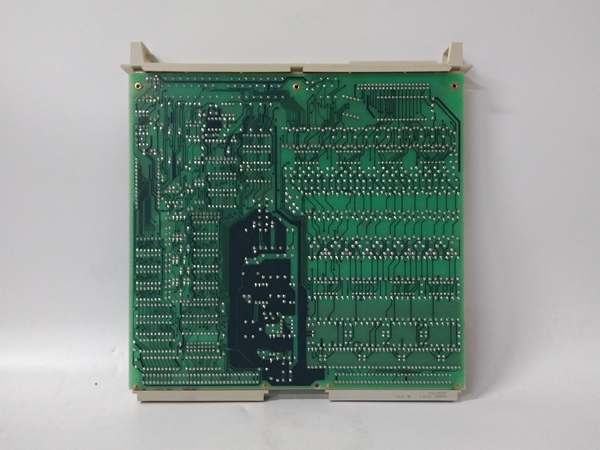

ABB DSCS131 57310001-LM

Technical Specifications

Model Number: MG200Q2YS40

Manufacturer: ABB

Product Type: Industrial Servo Motor

-

Function: Position servo control

-

Application: Industrial automation (robotics, machine tools, material handling)

-

Supplier: Shanghai Futian Automation Equipment Co., Ltd. (distributor)

-

Key Feature: High-precision motion control for industrial machinery

Core Features & Customer Value

1. High-Precision Motion Control:

The MG200Q2YS40 is designed for applications requiring exact positioning, such as robotic welding or CNC machining. Its precise control ensures consistent quality and reduces scrap, directly impacting customer profitability.

2. Dynamic Performance:

With fast acceleration and deceleration capabilities, the motor supports high-speed automation tasks, increasing throughput and efficiency in manufacturing lines.

3. Industrial-Grade Reliability:

Built to withstand harsh industrial environments, the motor’s robust design minimizes downtime and maintenance costs, ensuring continuous operation in critical applications.

4. Seamless Integration:

Compatible with ABB’s servo drives and controllers, the MG200Q2YS40 simplifies system design and setup, reducing integration time and effort for engineers.

ABB DSCS131 57310001-LM

Typical Applications

The ABB MG200Q2YS40 is widely used in industries requiring precise motion control:

-

Robotics:

-

Powers robotic arms for assembly, welding, or painting in automotive and electronics manufacturing.

-

Example: In an automotive assembly line, the motor positions a robotic arm to install doors with ±0.1 mm accuracy.

-

-

Machine Tools:

-

Controls spindle rotation or tool positioning in CNC milling or turning machines.

-

Example: A CNC lathe uses the MG200Q2YS40 to achieve precise cuts in metal parts, ensuring dimensional accuracy.

-

-

Material Handling:

-

Drives conveyor belts or hoists for transporting goods in warehouses or factories.

-

Example: A material handling system uses the motor to control the speed of a conveyor belt, synchronizing with robotic pick-and-place operations.

-