Description

Detailed parameter table

| Parameter name | Parameter value |

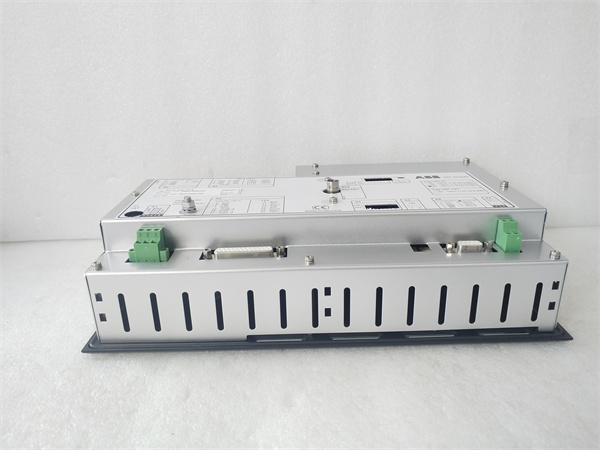

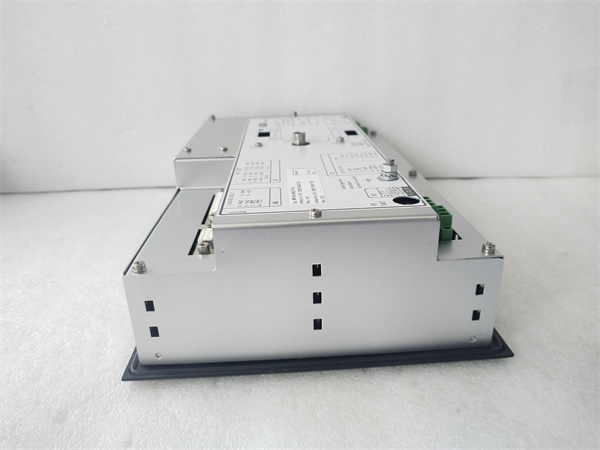

| Product model | MT-91-ARC FPA |

| Manufacturer | ABB |

| Product category | Robotic control display panel |

| Display type | 10.1-inch high-resolution color touchscreen (1280×800) |

| Operating system | Linux-based real-time OS |

| Processor | Quad-core ARM Cortex-A53 (1.8 GHz) |

| Memory | 4 GB RAM, 32 GB eMMC storage |

| Communication interfaces | 2×Ethernet (Gigabit), 2×USB 3.0, RS485, HDMI output |

| Supported protocols | PROFINET, EtherCAT, Modbus TCP, ABB Robot Communication Protocol |

| Operating temperature | 0°C to 50°C |

| Protection rating | IP65 (front panel), IP20 (rear connectors) |

| Mounting options | Panel mount, swing arm mount, or desktop stand |

| Power supply | 24 V DC ±10% (1.5 A typical) |

ABB MT-91-ARC FPA

Product introduction

The MT-91-ARC FPA is a cutting-edge robotic control display panel developed by ABB, specifically engineered for high-precision automation environments where reliability and user-centric operation are critical. As part of ABB’s Advanced Robotics Control series, MT-91-ARC FPA serves as the primary human-machine interface (HMI) for programming, monitoring, and troubleshooting robotic systems, bridging the gap between operators and complex automation workflows.

Equipped with a 10.1-inch high-resolution touchscreen and a powerful quad-core processor, MT-91-ARC FPA delivers responsive performance even when handling multiple tasks—from editing robot trajectories to analyzing real-time production data. Its robust design, including an IP65-rated front panel, ensures durability in harsh industrial settings, while seamless integration with ABB’s YuMi®, IRB, and SWIFTI robot families makes it a versatile solution across diverse manufacturing sectors. Whether deployed in automotive assembly lines or electronics production facilities, MT-91-ARC FPA enhances operational efficiency by simplifying complex robotic control processes.

Core advantages and technical highlights

Intuitive multi-touch interface: The MT-91-ARC FPA features a scratch-resistant, anti-glare touchscreen with multi-touch capability, allowing operators to zoom, pan, and swipe through robot programs and diagnostic data with the same familiarity as consumer devices. This reduces training time for new users by up to 40% compared to traditional button-based panels, while customizable widgets let experienced technicians configure the interface to prioritize critical metrics like cycle time or error rates.

Real-time data processing and visualization: Powered by a quad-core ARM processor and Linux-based real-time OS, MT-91-ARC FPA processes and displays robot telemetry—such as joint positions, speed, and torque—with sub-100ms latency. This enables operators to identify subtle performance deviations, like unexpected vibration in a welding robot, before they escalate into production errors. The panel’s 1280×800 resolution ensures clear visibility of 3D robot models and trajectory previews, simplifying path optimization for complex tasks.

Seamless robotic ecosystem integration: MT-91-ARC FPA natively supports ABB’s Robot Communication Protocol, enabling plug-and-play connectivity with IRB 6700, YuMi collaborative robots, and other ABB models. It also communicates via PROFINET and EtherCAT, allowing synchronization with PLCs, vision systems, and conveyor controls in a unified automation network. In a battery manufacturing facility, for example, this integration lets the panel coordinate a SWIFTI robot’s pick-and-place actions with upstream molding machines, reducing changeover time between battery cell types.

Durability for industrial environments: With an IP65-rated front panel, the MT-91-ARC FPA withstands water jets and dust ingress—critical for food processing or automotive paint shop applications where equipment is regularly washed down. Its operating temperature range of 0°C to 50°C ensures reliable performance in unconditioned factory spaces, while reinforced mounting options (panel, swing arm, or desktop) adapt to diverse workspace layouts without compromising stability.

Typical application scenarios

In automotive body-in-white production, MT-91-ARC FPA serves as the control hub for a fleet of ABB IRB 6700 welding robots. Operators use the panel’s touchscreen to adjust weld parameters—such as current, voltage, and wire feed rate—with real-time previews of how changes affect bead formation. The interface displays live camera feeds from vision systems mounted on the robots, allowing technicians to inspect weld seams without pausing production. When a robot encounters a calibration error, MT-91-ARC FPA automatically pulls up step-by-step troubleshooting guides with annotated images of the affected joint, reducing downtime by enabling faster diagnostics.

In electronics manufacturing, MT-91-ARC FPA controls YuMi collaborative robots assembling smartphone circuit boards. Its multi-touch interface lets operators drag-and-drop waypoints to teach the robot new component placement patterns, while the panel’s integration with Modbus TCP allows synchronization with upstream PCB conveyors. The IP65 rating ensures the panel remains operational in cleanrooms where periodic sanitization is required, and its compact size fits comfortably on workbenches alongside manual assembly stations—facilitating smooth collaboration between human workers and robots.

ABB MT-91-ARC FPA

Related model recommendations

ABB IRC5 Compact Controller: The primary robot controller that pairs with MT-91-ARC FPA to execute motion control algorithms and manage I/O for ABB robots.

ABB DSQC 679: A safety controller module that works with MT-91-ARC FPA to configure emergency stop parameters and collaborative robot safety zones.

ABB IRB 1200: A compact 6-axis robot commonly controlled via MT-91-ARC FPA in electronics and small-part assembly applications.

ABB YuMi IRB 14000: A dual-arm collaborative robot whose precision tasks, like micro-assembly, are programmed and monitored through MT-91-ARC FPA.

ABB 800xA DCS: A distributed control system that integrates data from MT-91-ARC FPA to provide plant-wide visibility of robotic cell performance.

ABB CI627A: A communication module that extends MT-91-ARC FPA’s connectivity to PROFIBUS networks for legacy equipment integration.

Installation, commissioning and maintenance instructions

Installation preparation: Mount MT-91-ARC FPA in a location with unobstructed visibility for operators, ideally within 1.5 meters of the robot workcell. For panel mounting, cut a 272×184 mm opening and secure the panel with the provided brackets, torquing screws to 0.8 Nm. For swing arm mounting, use ABB’s recommended articulated arm (part number 3HAC031684-001) to ensure flexibility without vibration. Connect power via a 24 V DC supply with a 2A fuse, and route Ethernet and USB cables through cable glands to maintain IP65 integrity. Power off all connected robots and controllers during installation to prevent data corruption.

Maintenance suggestions: Clean the MT-91-ARC FPA’s touchscreen daily with a soft, lint-free cloth dampened with isopropyl alcohol to remove oil and debris, avoiding abrasive cleaners that could scratch the surface. Inspect cable connections monthly for tightness, especially in high-vibration environments, and check for error codes in the system log weekly to address issues like intermittent communication with the robot controller. If the touchscreen becomes unresponsive, recalibrate it via the maintenance menu; for persistent hardware faults, replace the panel with an ABB-certified unit to ensure compatibility with robot firmware. Back up custom interface configurations to a USB drive quarterly to streamline recovery after software updates.

Service and guarantee commitment

MT-91-ARC FPA is backed by a 3-year warranty from the date of installation, covering defects in materials and workmanship under normal industrial use. ABB’s global technical support team provides 24/7 remote assistance for troubleshooting via phone or email, with response times guaranteed under 2 hours for critical issues that halt production. On-site service is available within 48 hours in major industrial regions for hardware repairs or complex integration challenges.

The warranty includes free access to firmware updates, which add new features like enhanced robot model support or improved data visualization tools. Extended service contracts offer annual preventive maintenance, including calibration checks and software optimization, to maximize panel performance over its 7-year design lifespan. ABB’s commitment to quality ensures that MT-91-ARC FPA remains a reliable interface between operators and robotic systems, minimizing downtime and maximizing productivity in automation environments.