Description

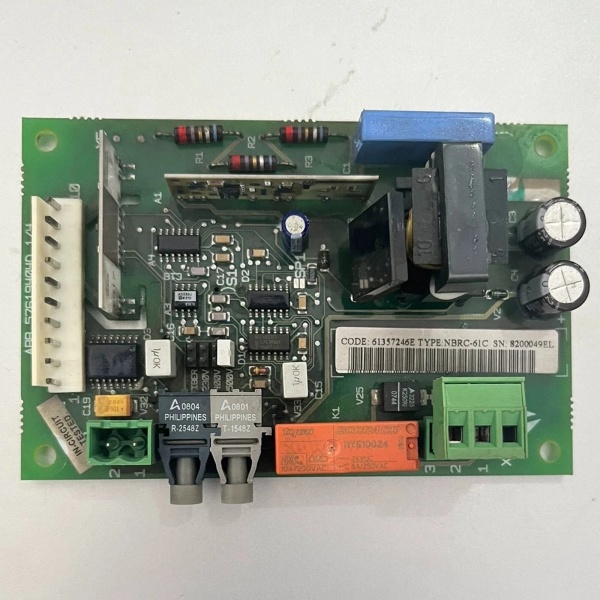

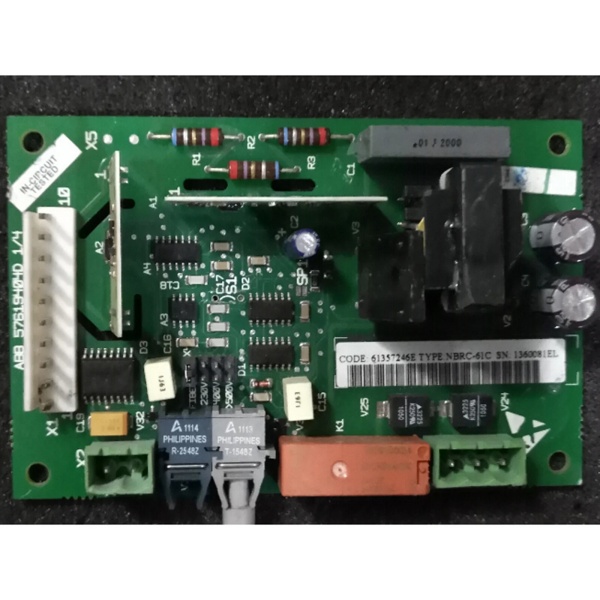

ABB NBRC-61

-

Model Number: NBRC-61 -

Manufacturer: ABB -

Product Type: Industrial Control Board (Chopper & Motor Control) -

Power Supply: 220V AC (±10%, 50/60Hz) or 12-24V DC (optional version) -

Output Frequency: 30-40 kHz (adjustable via software) -

Control Method: Chopper-based pulse-width modulation (PWM) -

Communication Interfaces: RS485 (Modbus RTU), Ethernet (Modbus TCP/IP, optional) -

Input Signals: Analog (0-10V, 4-20mA), Digital (24V DC, dry contact) -

Output Signals: PWM (to motor driver), Status relays (fault, ready) -

Enclosure Protection: IP20 (dust-protected, cabinet mount) -

Operating Temperature: -20°C to +60°C (extended storage: -40°C to +70°C) -

Humidity Range: 5-95% RH non-condensing -

Dimensions: 100mm x 100mm x 35mm (width x height x depth) -

Weight: 0.15kg -

Certifications: CE, UL, RoHS

NBRC-61